A Rotary Multi-station Automatic Flip and Reset Mechanism

A technology of automatic turning and reset mechanism, which is applied in the direction of hoisting device and hoisting device, etc. It can solve the problems that the automatic turning equipment cannot be widely used, the impact vibration and the noise are large, so as to shorten the layout length, reduce vibration and noise, and the method is simple Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the drawings:

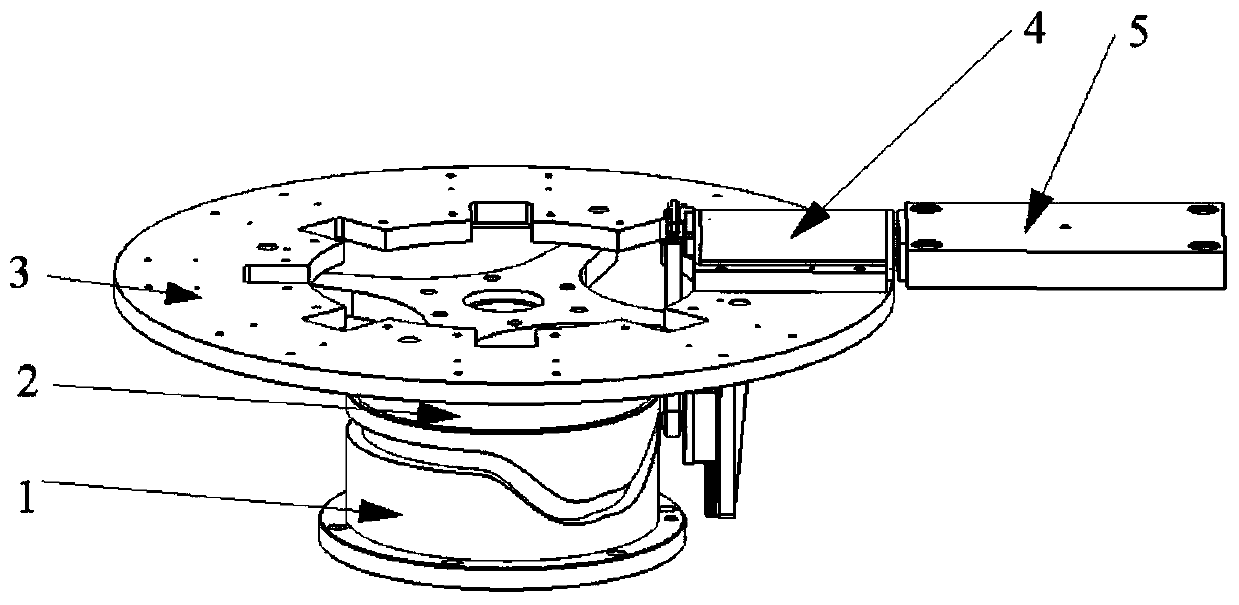

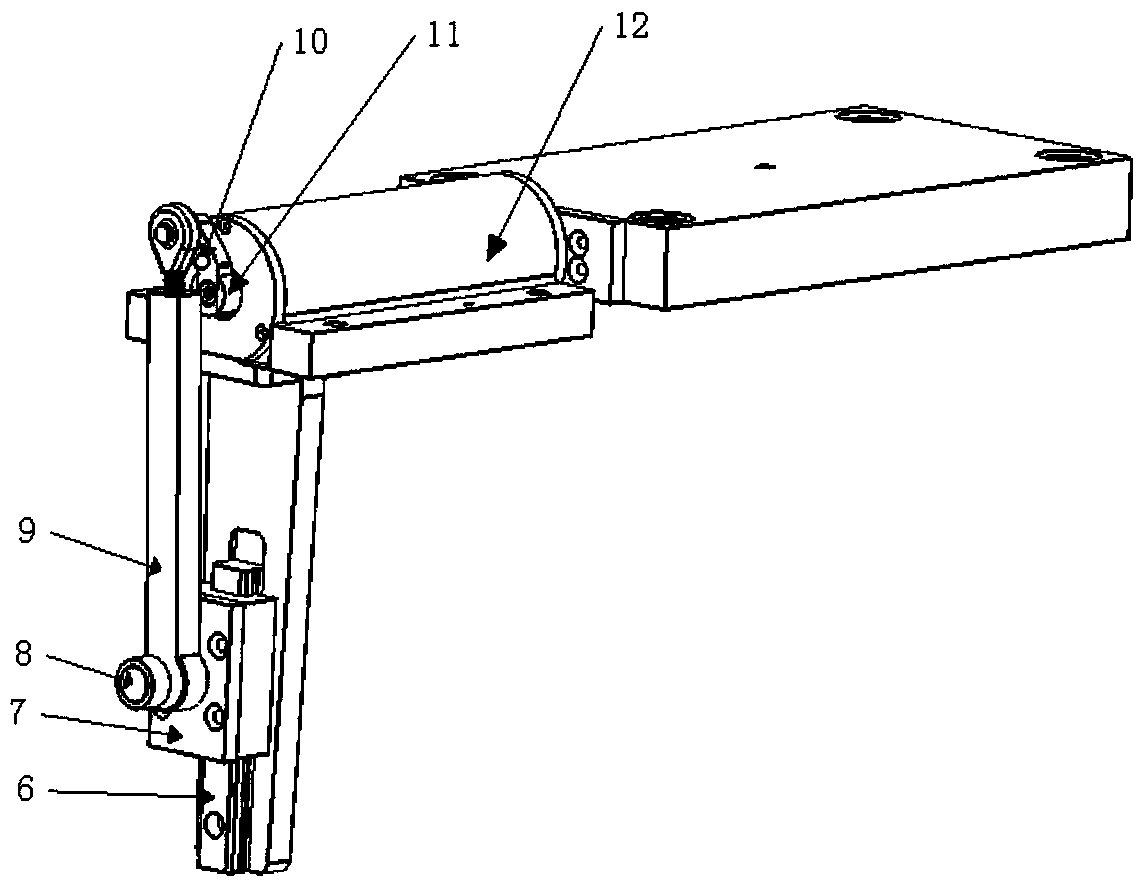

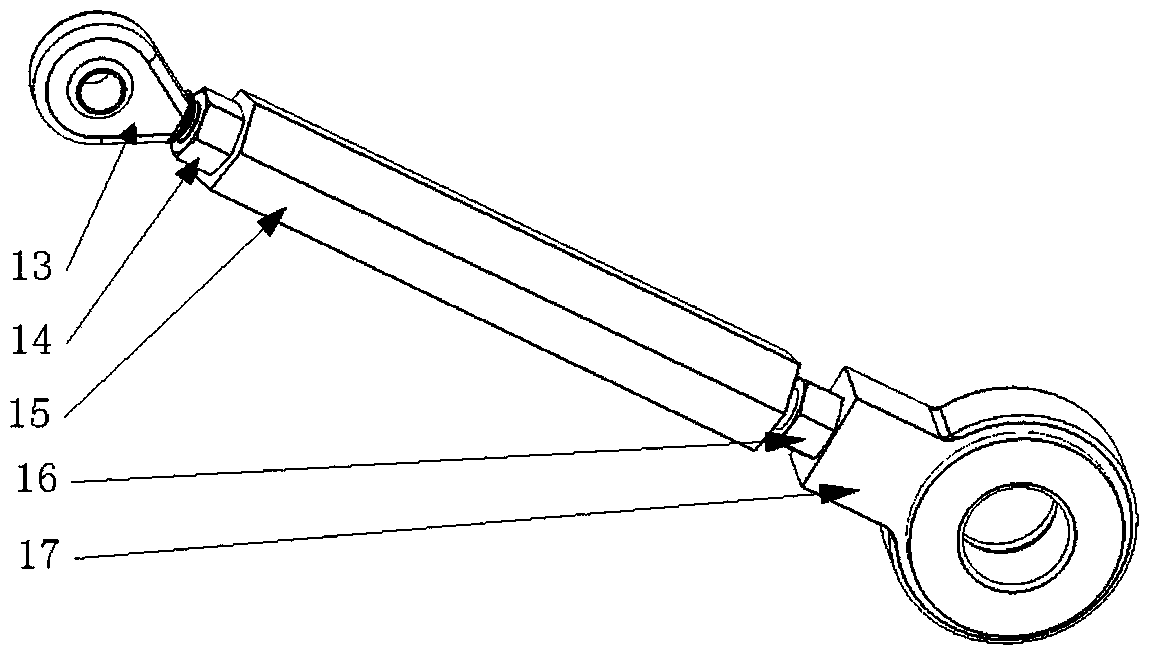

[0022] Such as figure 1 Shown is a schematic diagram of a rotary multi-station automatic turning and resetting mechanism. The rotary multi-station automatic turning and resetting mechanism of the present invention is characterized in that it includes a cylindrical cam (1), a slewing support (2), and a rotary platform ( 3), crank slider mechanism (4), turning platform (5). The cycle method adopted by the whole mechanism to repeatedly complete the flip and reset action is the periodic rotation mode. The cylindrical cam (1) is fixed, and the rotary power device drives the rotary platform (3) to rotate around the central axis of the cylindrical cam (1). The slewing bearing (2) is used as a rotating pair, and the slider crank mechanism (4) is fixedly installed on the slewing platform (3). When the slider crank mechanism (4) rotates with the slewing platform (3), the cylindrical c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com