Demand-based active anti-rollover hydraulic inline suspension system for heavy truck

A heavy-duty truck and suspension system technology, applied in the field of vehicle safety, can solve the problems of reduced vehicle ride comfort, low reliability, and difficulty in ensuring reliability, achieving high dynamic response performance, saving operating costs, and easy modification and implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

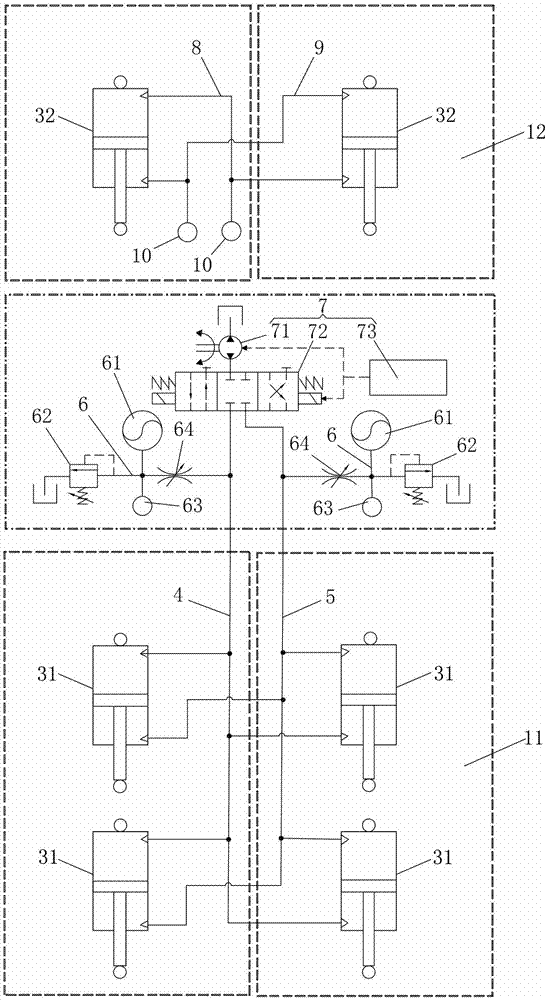

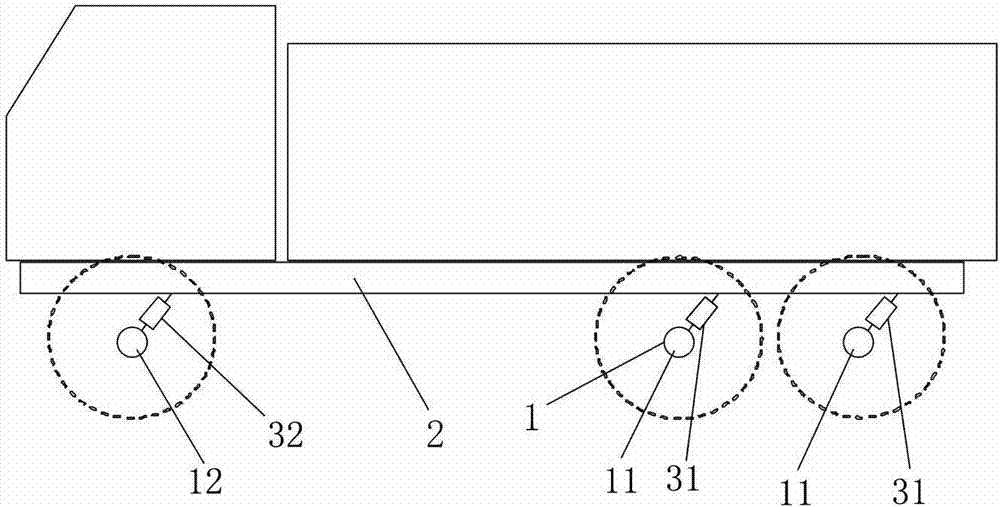

[0035] figure 1 with figure 2It shows an embodiment in which the on-demand active anti-rollover hydraulic inline suspension system for heavy trucks of the present invention is applied to three-axle vehicles. The on-demand active anti-rollover hydraulic inline suspension system includes The middle and rear axle anti-rollover hydraulic system between the middle and rear axle 11 and the vehicle frame 2, the middle and rear axle anti-rollover hydraulic system includes four middle and rear axles supported between the middle and rear axle 11 of the vehicle axle 1 and the vehicle frame 2 Rear axle oil cylinder 31, four middle and rear axle oil cylinders 31 are symmetrically arranged on the left and right sides of vehicle frame 2, and each middle and rear axle oil cylinder 31 is connected with vehicle axle 1 and vehicle frame 2 through a ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com