Manufacturing method of target material assembly

A manufacturing method and target material technology, applied in metal material coating technology, ion implantation plating, coating, etc., can solve the problems of large sandblasting force, affecting yield, and weak adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

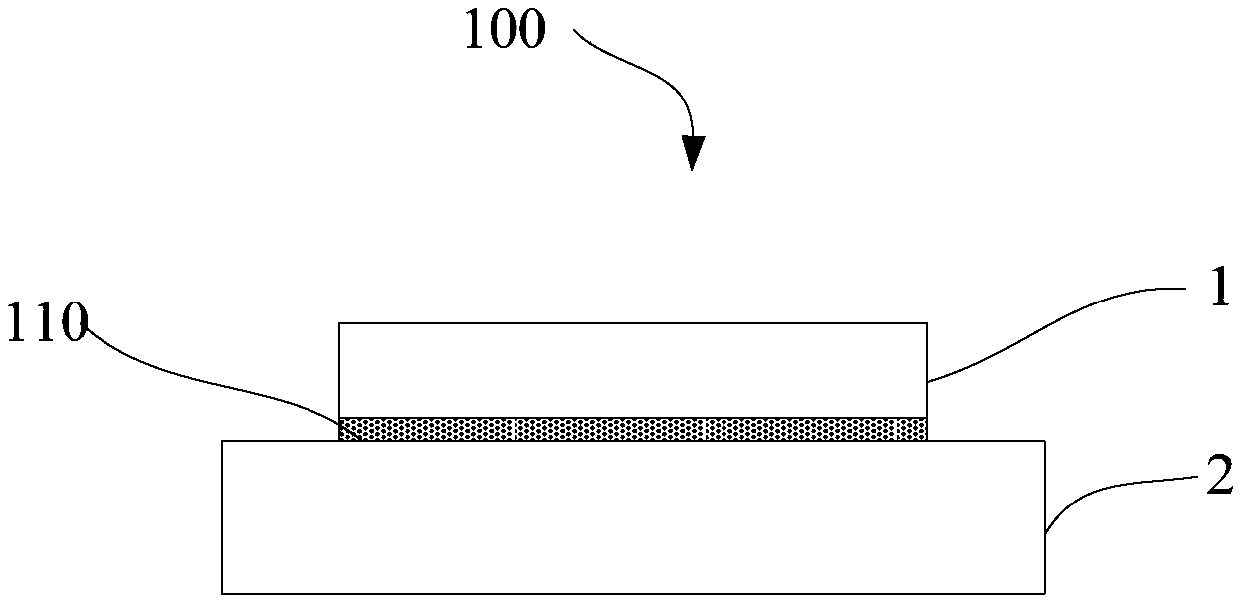

[0028] Figure 1 to Figure 3 It is a structural diagram corresponding to each step in the first embodiment of the manufacturing method of the target assembly of the present invention.

[0029] first reference figure 1 , providing a target assembly 100, the target assembly 100 includes a target 1 and a backing plate 2, and the target 1 is connected to the backing plate 2.

[0030] In this embodiment, the shape of the target 1 is a cuboid. In other embodiments, the shape of the target 1 may be a cylinder, an elliptical cylinder or other shapes.

[0031] In this embodiment, Velcro 110 is provided at the joint between the target 1 and the backboard 2 .

[0032] In other embodiments, double-sided adhesive tape and the like may also be provided at the joint between the target material 1 and the back plate 2 .

[0033] In this embodiment, adhesive tape is used to realize the bonding of the Velcro 110 and the target 1 . In other embodiments, glue and the like can be used to bond ...

no. 2 example

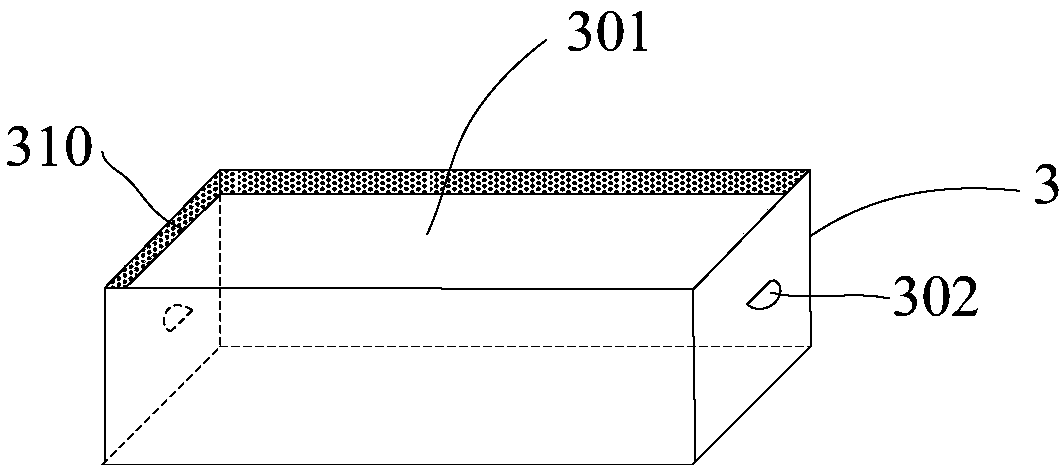

[0051] Figure 4 It is a structural schematic diagram of the set in the second embodiment of the manufacturing method of the target assembly of the present invention.

[0052] The difference between the second embodiment and the first embodiment is only that the set in the first embodiment is integrally formed, while the set in the second embodiment is formed step by step.

[0053] first reference Figure 4 , providing an inner sleeve 4, the side of the inner sleeve 4 is arranged in two layers.

[0054] In this embodiment, the inner sleeve 4 has an opening 401, and the inner sleeve 4 is also in the shape of a cuboid, which is due to figure 1 It is determined by the shape of the target material 1.

[0055] Taking one side of the inner sleeve 4 as an example, the two-layer structure of the side and the connection between the two layers are introduced.

[0056] In this embodiment, the sides include a first side 410 and a second side 420 .

[0057]In this embodiment, the fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com