Field 3D printed wall column structure and construction method thereof

A technology of 3D printing and printing walls, which is applied in the direction of building structures, walls, building components, etc., and can solve the problems of printing construction, poor building integrity of structural columns, and high building costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

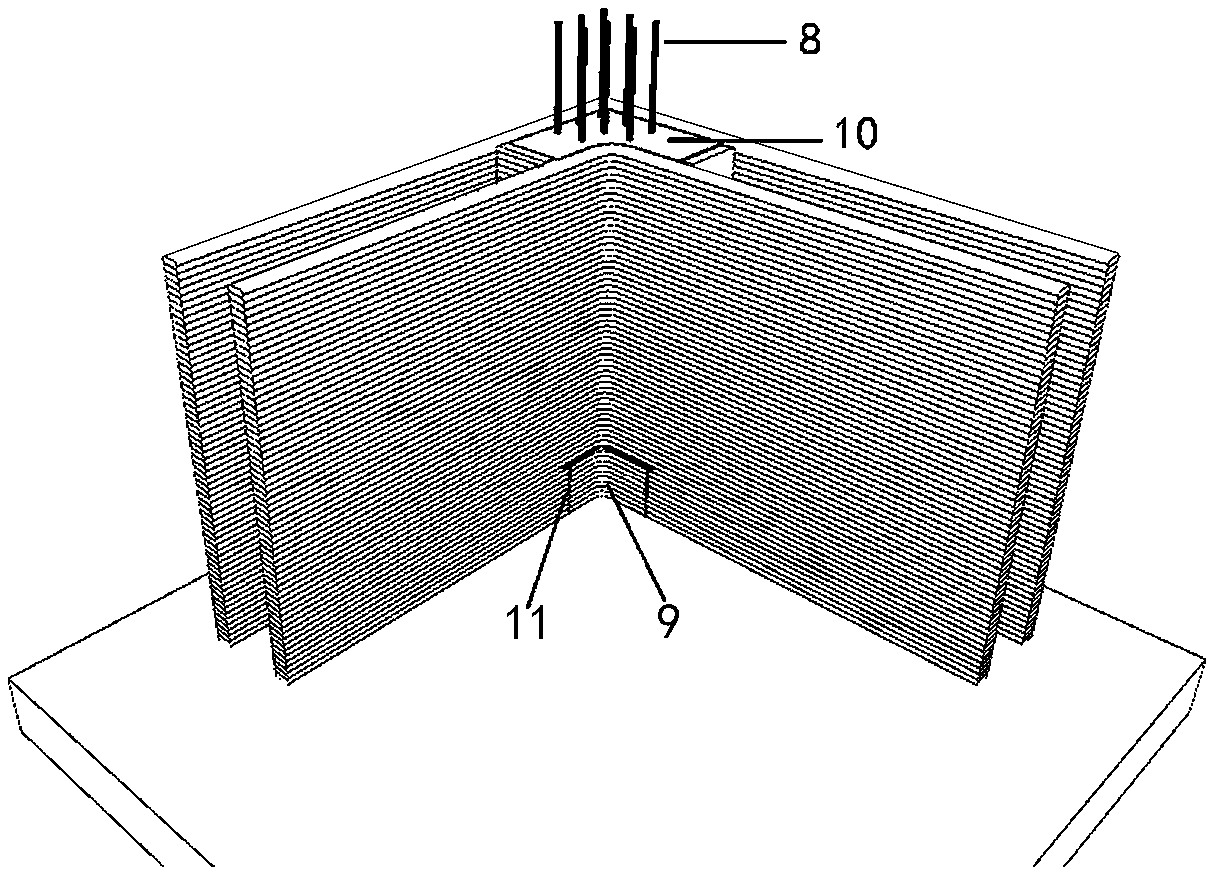

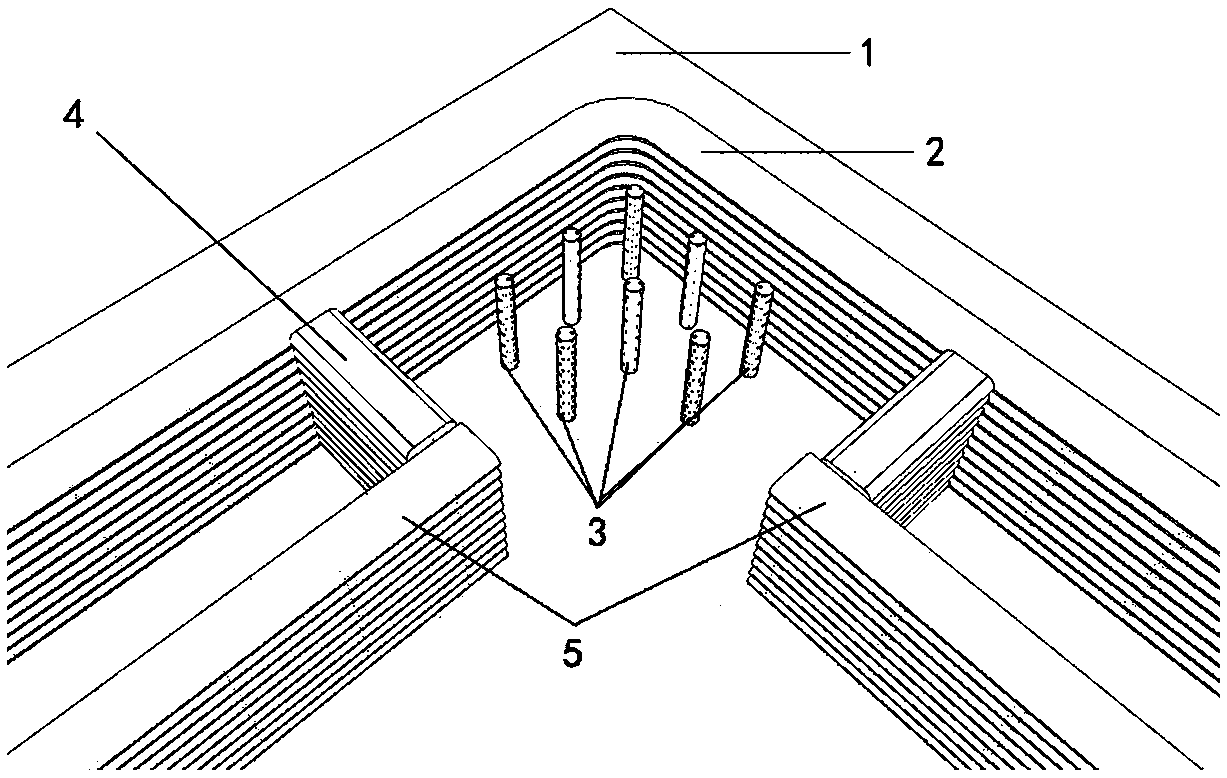

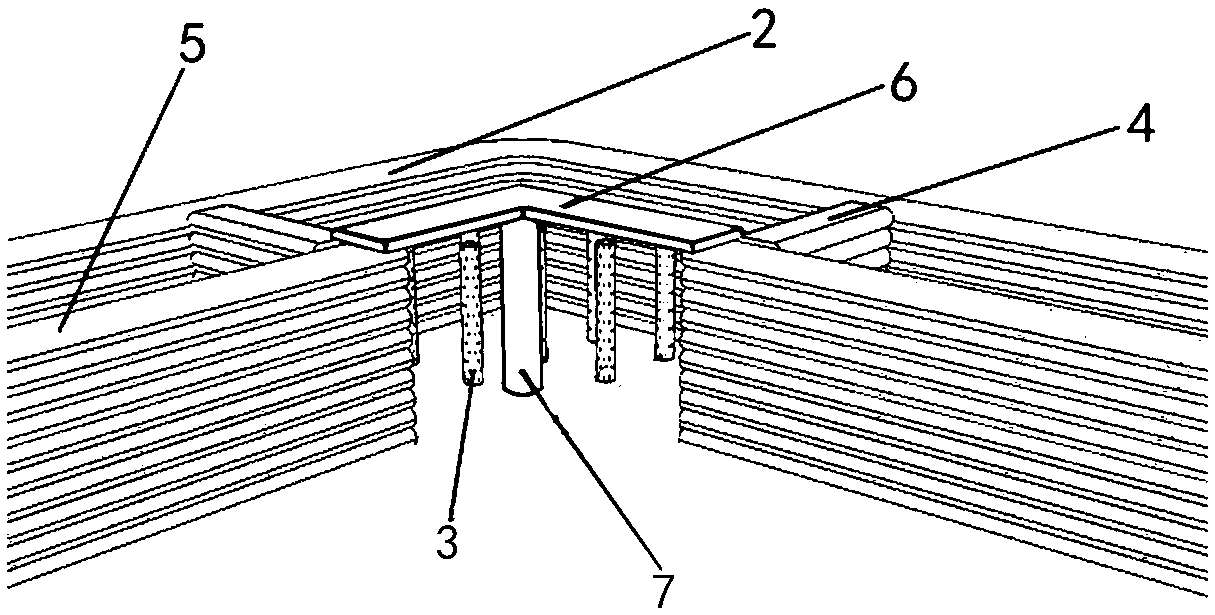

[0040] see Figure 1-7 As shown, an on-site 3D printed wall column structure, including concrete structure bottom plate 1, pre-embedded steel bar 3, opening lintel 6, structural column reinforcement cage, 3D printed outer wall 2, 3D printed inner wall 5, 3D printed Ribs 4 and cast-in-place column concrete 10 in the wall, and the structural column reinforcement cage includes vertical main reinforcement 8 and horizontal reinforcement.

[0041] The shape of the 3D printed outer wall 2 and the 3D printed inner wall 5 are both L-shaped. The 3D printed inner wall 5 is located inside the 3D printed outer wall 2. The corners of the printed inner wall 5 and two 3D printed inner wall ribs 4 are jointly enclosed to form a column formwork for pouring the cast-in-place column concrete 10, and the two ends of the 3D printed inner wall ribs 4 are respectively fixed and connected to the 3D Print the outer side of the inner wall body 5 and the inner side of the 3D printed outer wall body 2 . ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com