Welding-free and paint-free color steel door body, door frame and assembled metal door

A non-welding, color steel technology, applied in the direction of window/door frame, door leaf, corner joint/side joint, etc., can solve the problems of knocking, scratching, jamming, pressing, high foreign trade transportation cost, dust pollution and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

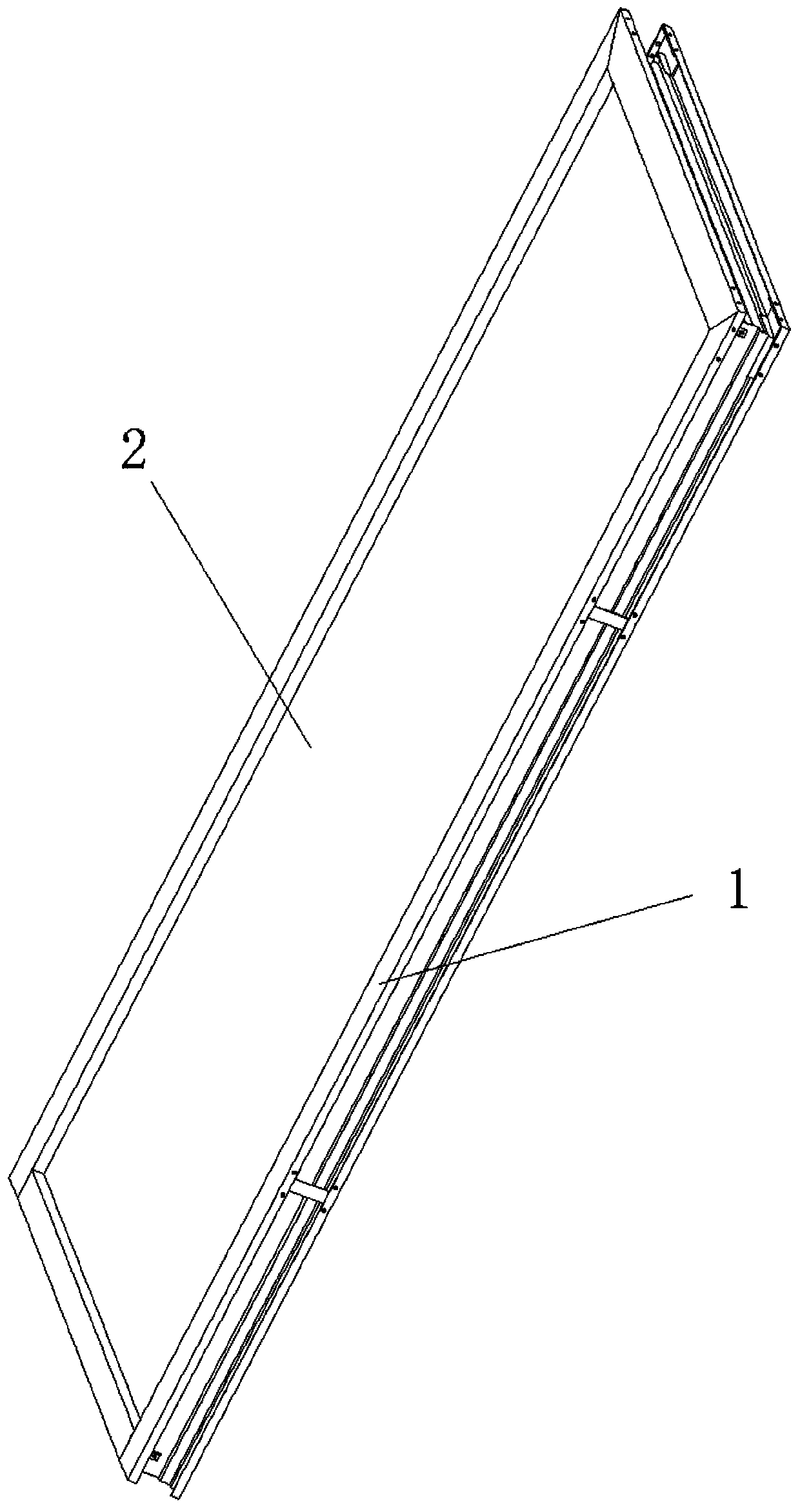

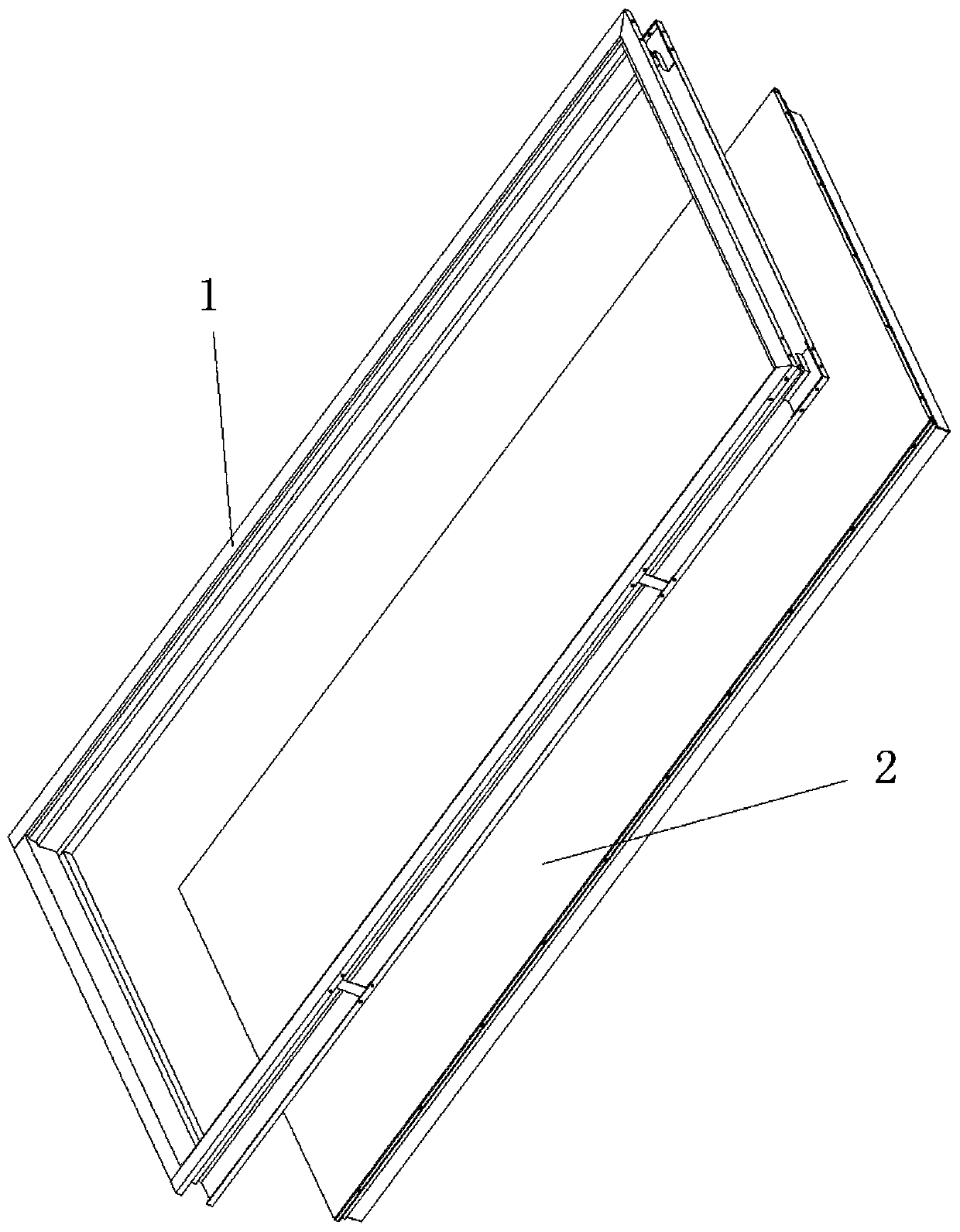

[0066] Please refer to Figure 1 to Figure 2 A non-welded assembled metal door is shown, which includes a door frame 1 and a door body 2, the door body 2 is located in the door frame 1, and the two are compatible, specifically, one side of the door body 2 passes through two or more A hinge is rotatably installed on the door frame 1, and the door frame 1 has a limiting frame that limits the opening direction of the door body 2 and closes the door body 2 and the door frame 1. The other side of the door body 2 is connected to the door frame 1 by a lock. Connection, wherein, locks and hinges are common structures in the prior art, not shown in the figure.

[0067] The metal door is a metal anti-theft door or a metal fire-proof door, and in this embodiment is an anti-theft door. In addition, in this embodiment, the paint-free color steel plate is a digitally printed color steel plate, which uses cold-rolled steel plate, electro-galvanized steel plate, hot-dip galvanized steel plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com