Direct type LED panel lamp automatic assembly line and assembly process

An LED panel light, direct type technology, applied in lighting devices, transportation and packaging, conveyor objects, etc., can solve the problems of low degree of automation, low efficiency, high labor cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

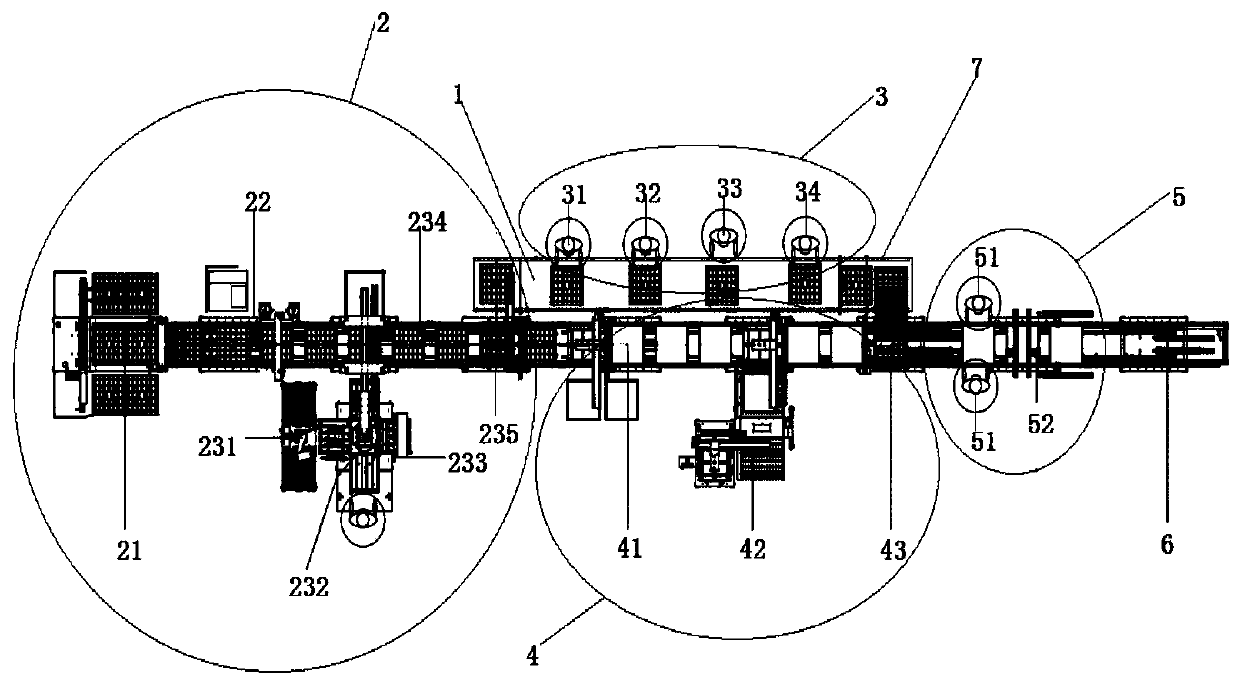

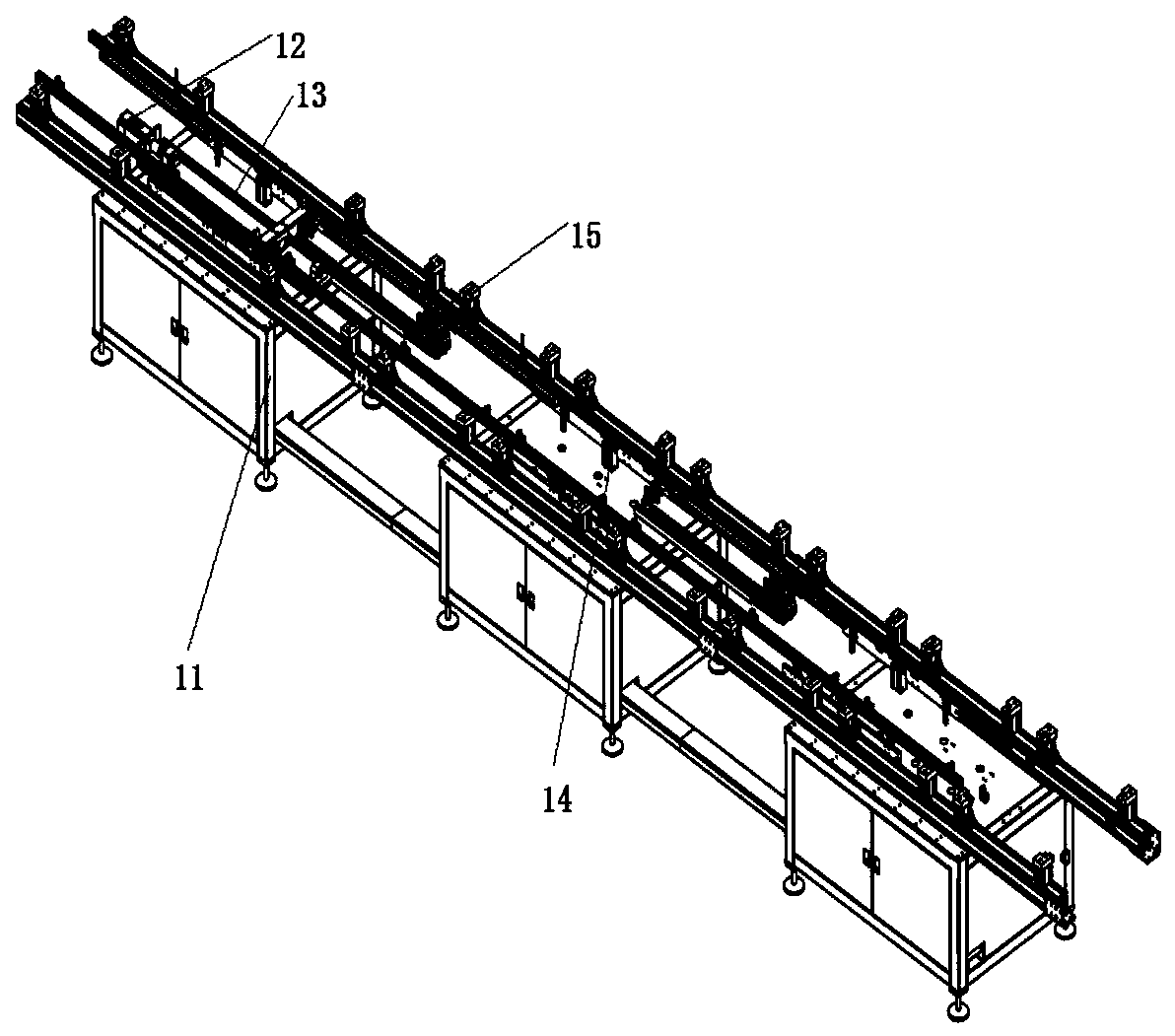

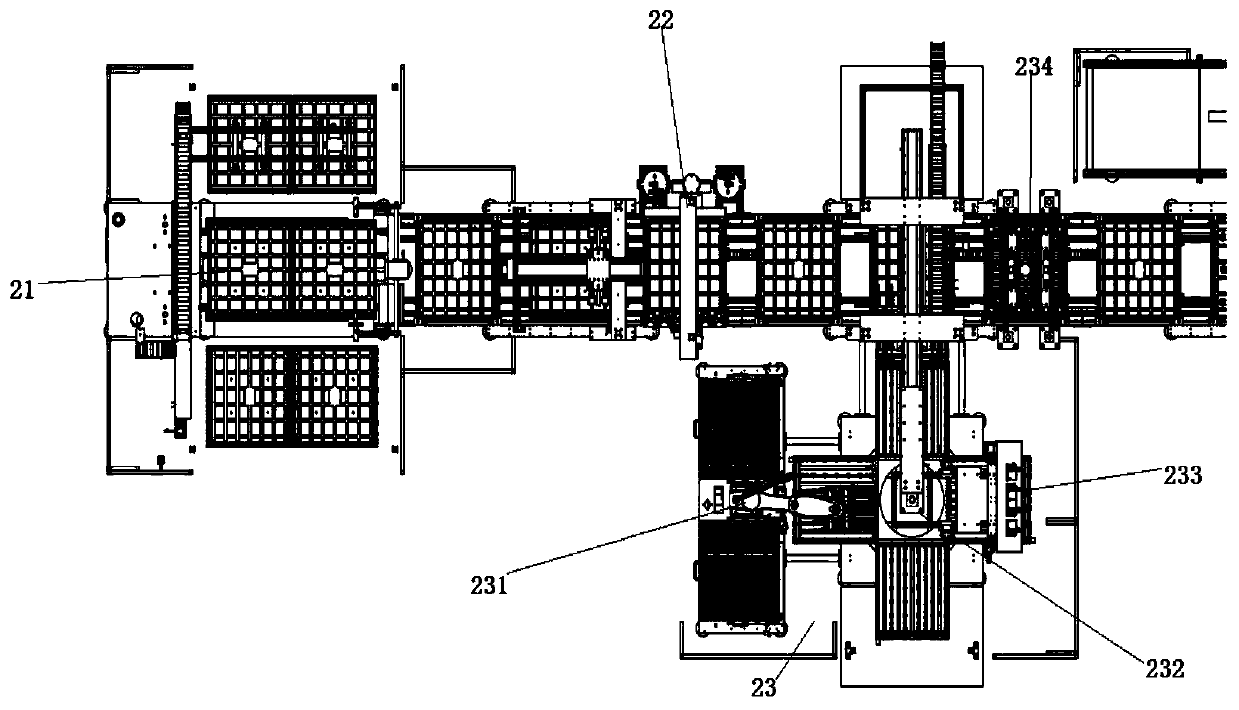

[0050] Such as Figure 1 to Figure 10 As shown, a direct-type LED panel light automatic assembly line, including material progressive handling unit 1, bottom shell automatic lighting module section 2, manual assistance section 3, surface frame and diffusion plate automatic cleaning installation section 4, screw lock Attached area 5 and unloading station 6, the bottom shell automatically installs the lighting module 2 includes an automatic bottom shell area 21, a glue dispensing station 22, and a lighting module automatic welding and light board placement station 23, the glue dispensing station 22 includes a bottom Shell point hot melt glue area 221 and bottom shell point silicone area 222, manual assistance section 3 includes manual welding drive connecting line section 31, manual driver clamping line buckle section 32, artificial point driver f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com