Flexible job shop scheduling method of co-fusion AGV

A flexible operation and workshop scheduling technology, applied in the direction of instruments, calculation models, data processing applications, etc., can solve the problems of genetic algorithm local optimal solution and low local search efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

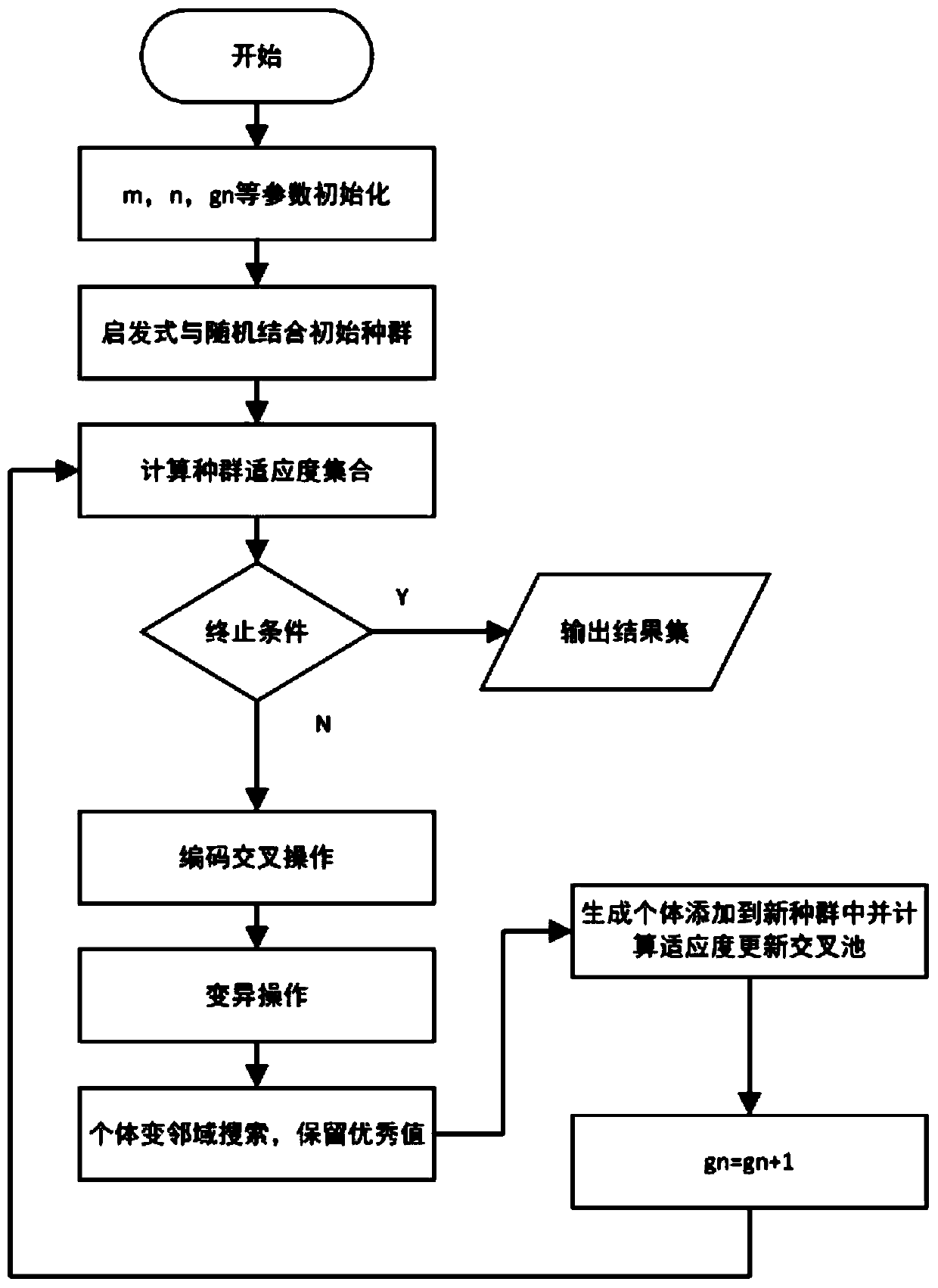

Method used

Image

Examples

Embodiment

[0082] Table 1 shows an example of a 3×4FJSP problem. The data in the table represent the time spent on processing the process on the corresponding machine, and the handling time of AGV between machines is shown in Table 2.

[0083] Table 1 Example of 3×4FJSP problem

[0084]

[0085] Table 2 AGV handling time

[0086]

[0087] Set the initial parameters according to the table.

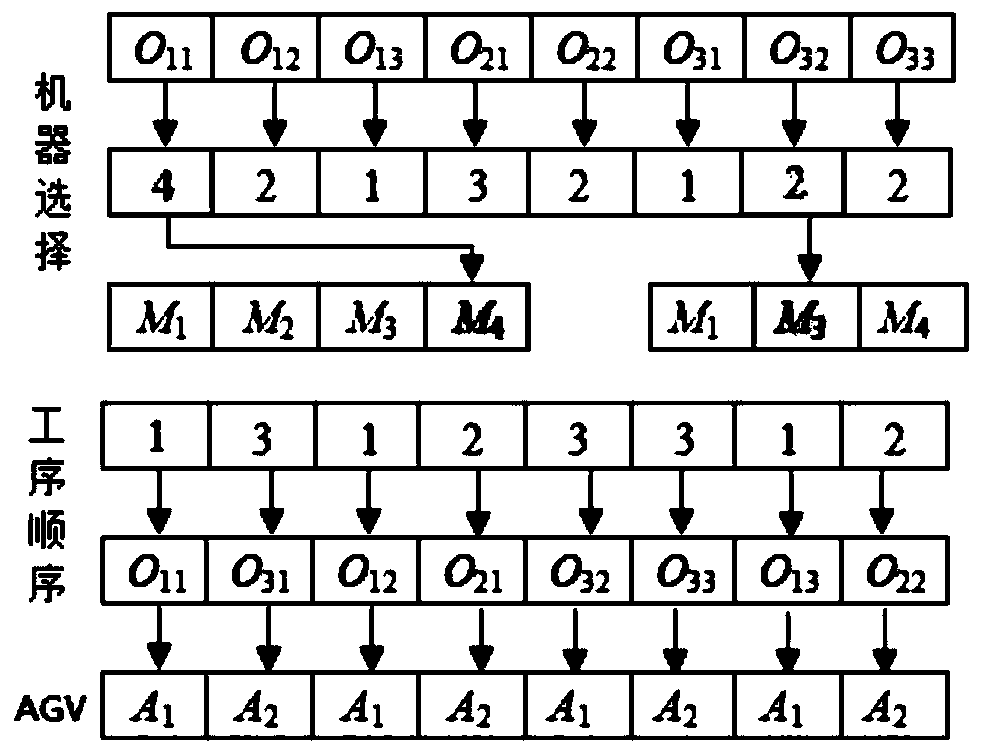

[0088] The FJSP problem involving AGV handling consists of three sub-problems: machine selection, process sequencing, and AGV sequence coding. According to the constraints of different machine processing time and idle conditions, select the appropriate machine for each process, and then sort the processes of the workpieces. Finally, AGV handling sequences are generated according to the process code in an evenly distributed manner, and the processing sequence and time are determined. The final encoding structure is as figure 2 As shown, the number of the machine selection code indicates which...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com