New fuel cell end plate structure

A single cell and end plate technology, applied in fuel cells, circuits, electrical components, etc., can solve problems such as single cell service life and uneven contact resistance distribution that affect the working efficiency of fuel cells, so as to improve overall performance, improve efficiency, The effect of uniform pressure distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

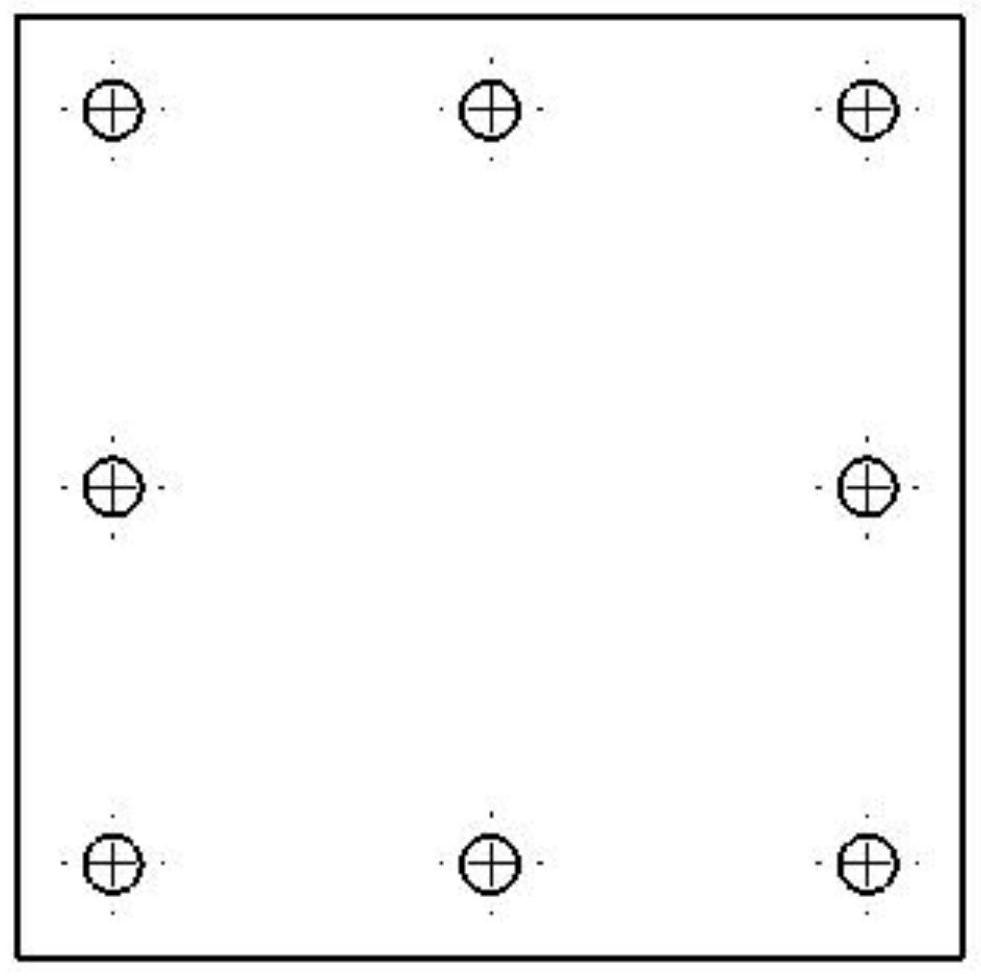

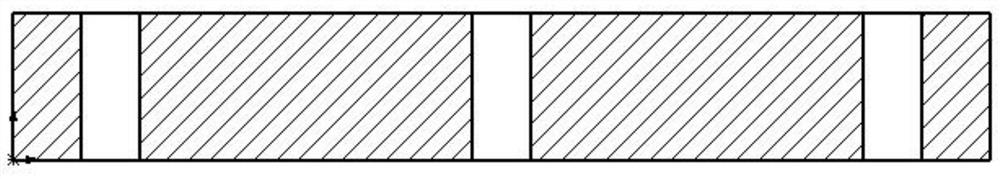

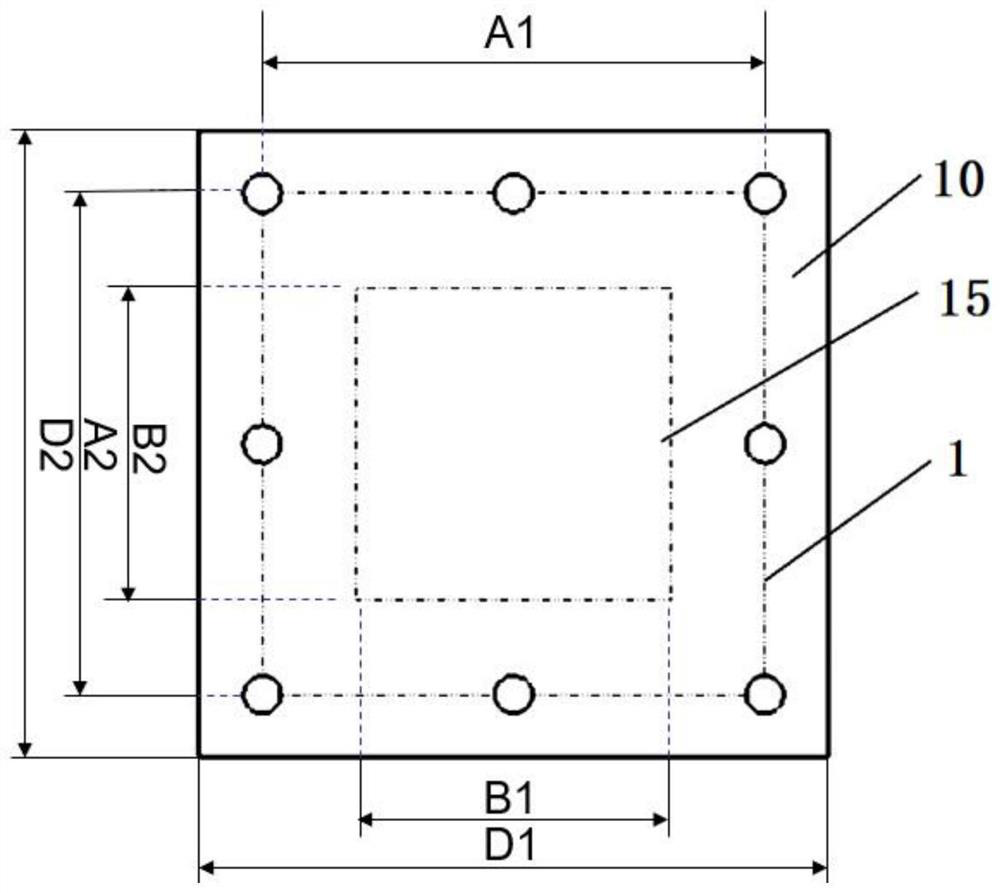

[0025] Such as Figure 6 The axial side structure diagram of the new single fuel cell end plate is shown, and there are 8 evenly distributed bolt holes around the end plate of the fuel cell end plate, which are connected to other structural components of the fuel cell through connecting bolts. There is a circle of deep grooves on the lower surface of the end plate. The distance from the deep groove to the side of the end plate is the same as the distance from the bolt hole to the side of the end plate. The central part of the lower end surface is provided with a boss whose relative position is the same as the active area of the fuel cell membrane electrode. The position is consistent, the size of the boss is the same as the maximum size of the active area, the height of the boss is consistent with the depth of the deep groove, which...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com