Piezoelectric ceramic driver clamping structure, linear driving device and periscopic lens

A piezoelectric ceramic and clamping structure technology, applied in the field of piezoelectric motors, can solve problems such as unavailability of side space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

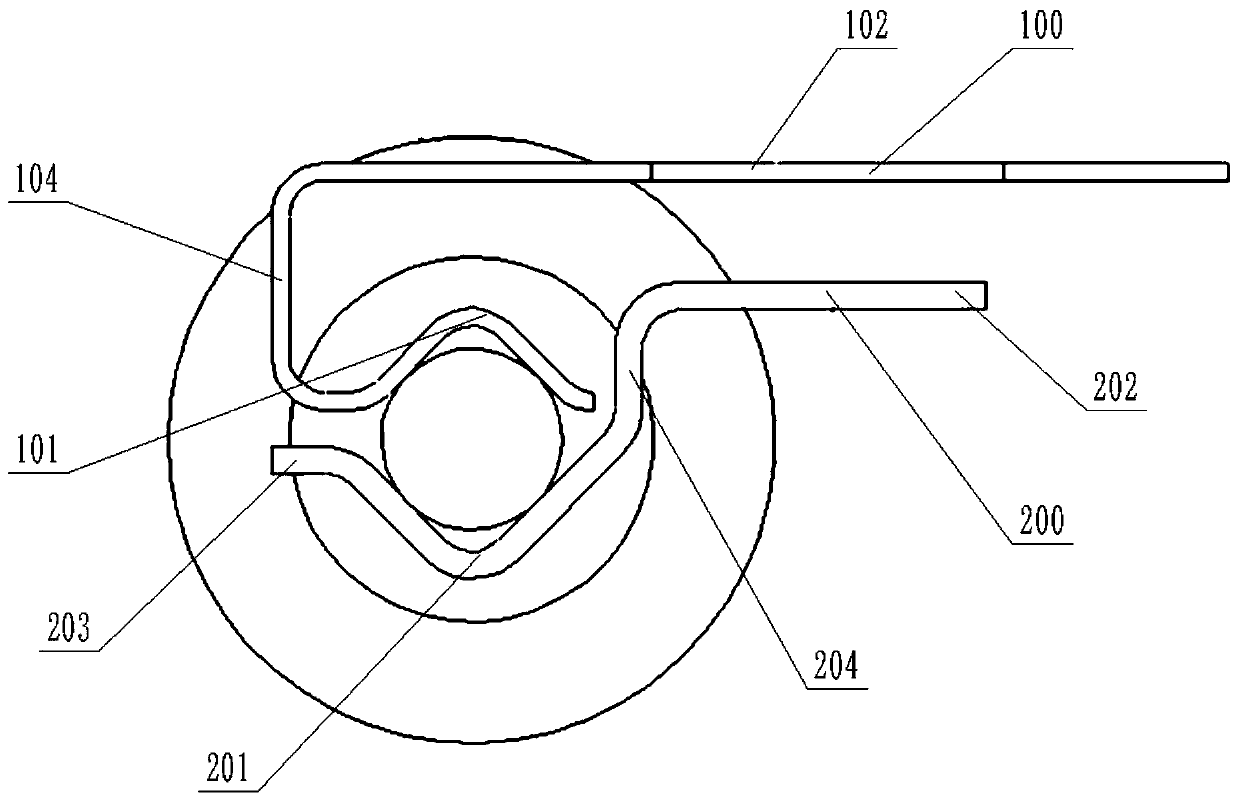

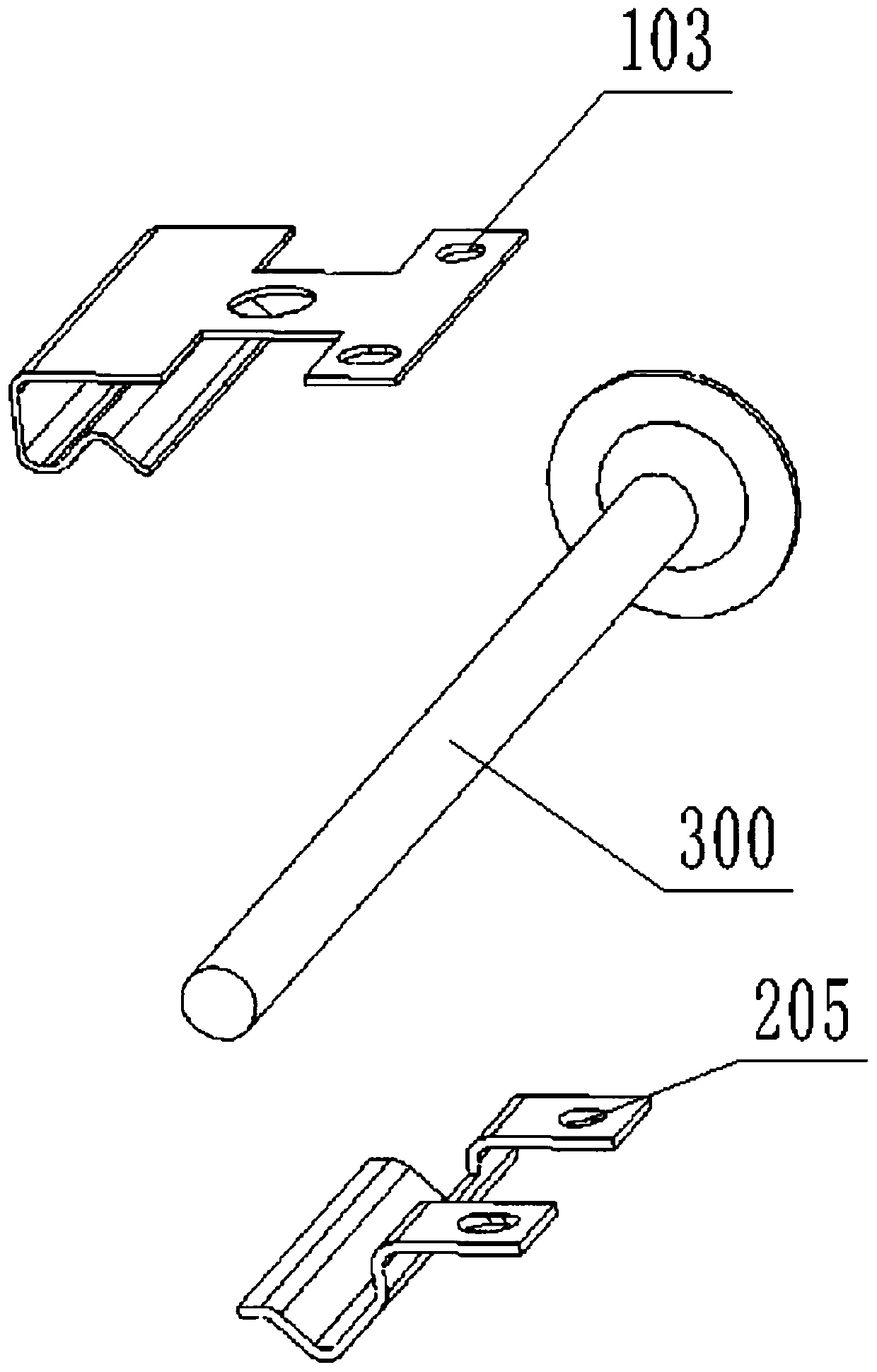

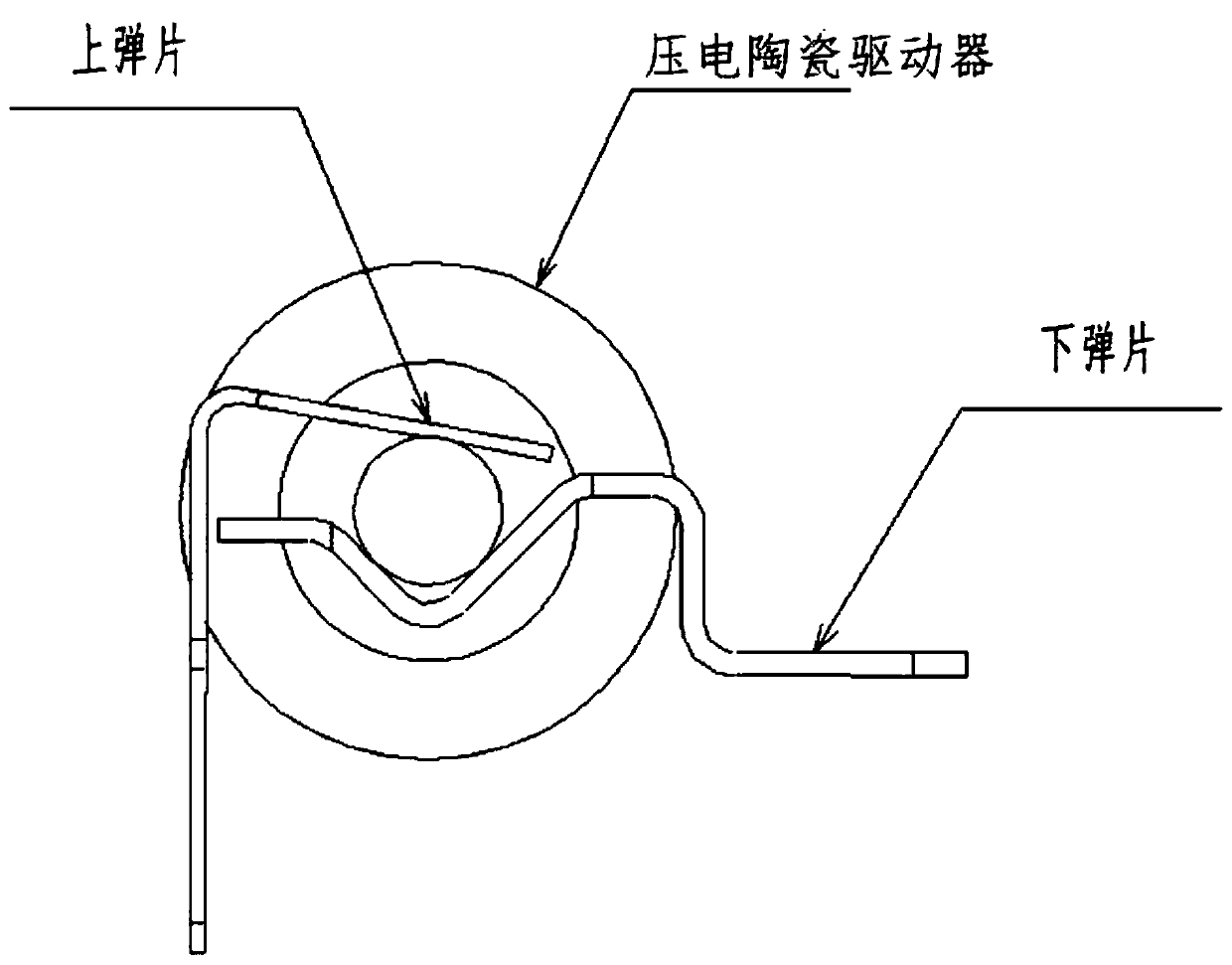

[0039] Example 1, please refer to Figure 1-4 , a clamping structure of a piezoelectric ceramic driver, comprising an upper elastic piece 100 and a lower elastic piece 200,

[0040] The upper elastic sheet 100 includes an integrally formed upper elastic sheet holding part 101 and an upper elastic sheet placement part 102. The upper elastic sheet placement part 102 is arranged horizontally, wherein the upper elastic sheet placement part 102 is in an I-shaped shape, and an upper installation hole is opened on the right side of the placement 103, the left end of the upper shrapnel placement part 102 is bent downward by 90 degrees to form an upper shrapnel vertical part 104, and the connection between the upper shrapnel placement part 102 and the upper shrapnel vertical part 104 is arranged in a circular arc transition, and the upper shrapnel vertical part 104 Bending 90 degrees to the right is connected with the upper elastic sheet holding part 101, and the connection between the...

Embodiment 2

[0045] Example 2, please refer to Figure 5-11 , a linear drive device, including the clamping structure of the above-mentioned piezoelectric ceramic driver, and also includes a frame body 400, a zoom lens bracket 500, a focusing lens bracket 600, a guide mechanism 700, and a piezoelectric ceramic driver 300;

[0046] The frame body 400 is a rectangular frame body with upper and lower openings, the upper and lower ends of the frame body 400 are provided with cover plates 401, and the cover plate 401 is fastened to the frame body 400;

[0047] Specifically, the left and right sides of the frame body are provided with fastening blocks 402, the left and right sides of the cover plate 401 are bent at 90 degrees, and the bent part is provided with a fastening groove adapted to the fastening block 402. 403;

[0048] The guide mechanism 700 is used to carry the zoom lens holder 500 and the focus lens holder 600 and make it slide on the guide mechanism 700. The guide mechanism 700 in...

Embodiment 3

[0058] Embodiment 3, the present invention also provides a periscope lens, including the linear drive device, and the periscope lens also includes a multi-reflection periscope ultra-telephoto structure, that is, by setting several The mirror structure is used to reflect multiple times to extend the optical path. Compared with the ordinary periscope lens, the optical path ratio is improved, and the telephoto is improved.

[0059] A telephoto lens has a long focal length, a small viewing angle, and a large image on the film. Therefore, at the same distance, it can shoot a larger image than the standard lens, which is very suitable for shooting distant objects. At the same time, because its depth of field is smaller than that of the standard lens, it can more effectively blur the background and highlight the focused subject. The subject and the camera are generally far apart, and the distortion in the perspective of the portrait is small, and the portrait will be more vivid. At t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com