A scraping oil for dispelling dampness and dispelling cold, warming the middle and relieving pain and preparation method thereof

A technology of warming and relieving pain and scraping oil, which is applied to non-central analgesics, medical preparations with no active ingredients, medical preparations containing active ingredients, etc., to achieve the effects of regulating qi, blood, yin and yang, relieving pain, and treating inflammation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

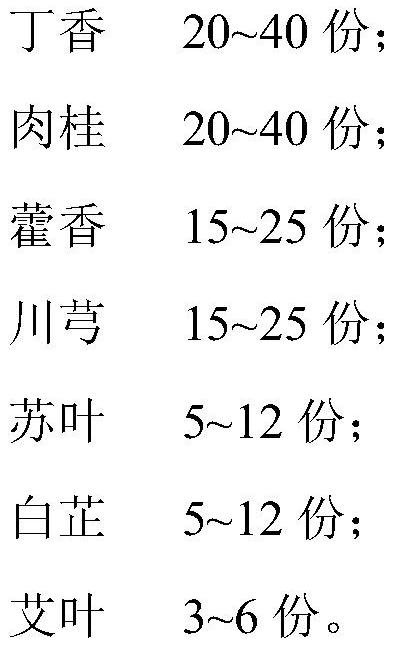

Method used

Image

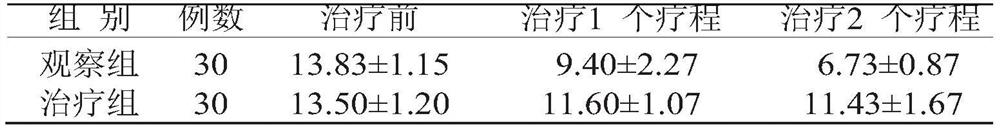

Examples

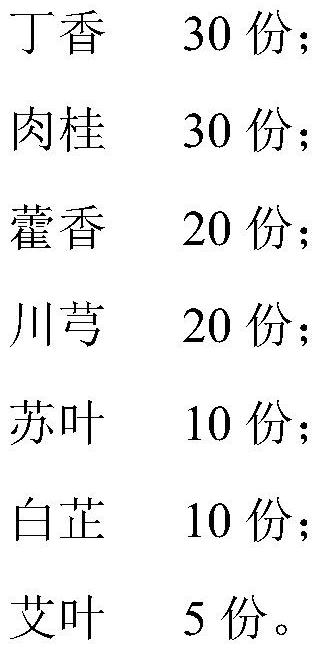

Embodiment 1

[0061]Chinese drug composition consisting of: cloves 30g, cinnamon 30g, Agastache 20g, Chuanxiong 20g, sage 10g, Angelica 10g, leaves 5g.

[0062] (1) mixing raw materials drugs, using an attritor pulverization of the drug, controlling the rotational speed of 1000r / min, pulverized at room temperature for 20 minutes through a 100 mesh sieve to obtain a crude powder material;

[0063] (2) The step (1) of crude powder material was charged in the extraction vessel, and then charged into the extraction kettle liquid CO 2 And boosting thermostat, the temperature control of the extraction vessel 50 ℃, a pressure of 50 MPa, the extraction time of 3 hours, so that the active ingredient in the powder crude material was dissolved in volatile liquid CO 2 And then the dissolved solution into the separator with a drug extract, the pressure within the separator is controlled to 10 MPa or, a temperature of 50 ℃, be liquid CO 2 Gasification, to give after separation drug extract;

[0064] (3) St...

Embodiment 2

[0066] Chinese drug composition consisting of: cloves 20g, cinnamon 20g, Agastache 15g, Chuanxiong 15g, sage 5g, Angelica 5g, leaves 3g.

[0067] (1) mixing raw materials drugs, using an attritor pulverization of the drug, controlling the rotational speed of 800r / min, pulverized at room temperature for 30 minutes through a 100 mesh sieve to obtain a crude powder material;

[0068] (2) The step (1) of crude powder material was charged in the extraction vessel, and then charged into the extraction kettle liquid CO 2 And boosting thermostat, the temperature control of the extraction vessel 20 ℃, a pressure of 40MPa, the extraction time of 4 hours, so that the active ingredient in the powder crude material was dissolved in volatile liquid CO 2 And then the dissolved solution into the separator with a drug extract, the pressure within the separator is controlled to 4MPa, a temperature of 40 ℃, be liquid CO 2 Gasification, to give after separation drug extract;

[0069] (3) Step (2) o...

Embodiment 3

[0071] Chinese drug composition consisting of: cloves 40g, cinnamon 40g, Agastache 25g, Chuanxiong 25g, sage 12g, Angelica 12g, leaves 6g.

[0072] (1) mixing raw materials drugs, using an attritor pulverization of the drug, controlling the rotational speed of 1000r / min, pulverized at room temperature for 30 minutes through a 100 mesh sieve to obtain a crude powder material;

[0073] (2) The step (1) of crude powder material was charged in the extraction vessel, and then charged into the extraction kettle liquid CO 2 And boosting thermostat, the temperature control of the extraction vessel 65 ℃, a pressure of 30MPa, extraction time of 1 hour, so that the active ingredient in the powder crude material was dissolved in volatile liquid CO 2 And then the dissolved solution into the separator with a drug extract, the pressure within the separator is controlled to 12MPa, temperature 30 ℃, be liquid CO 2 Gasification, to give after separation drug extract;

[0074] (3) Step (2) obtaine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com