A mof@tio 2 @pdvb photocatalyst and its preparation method and application

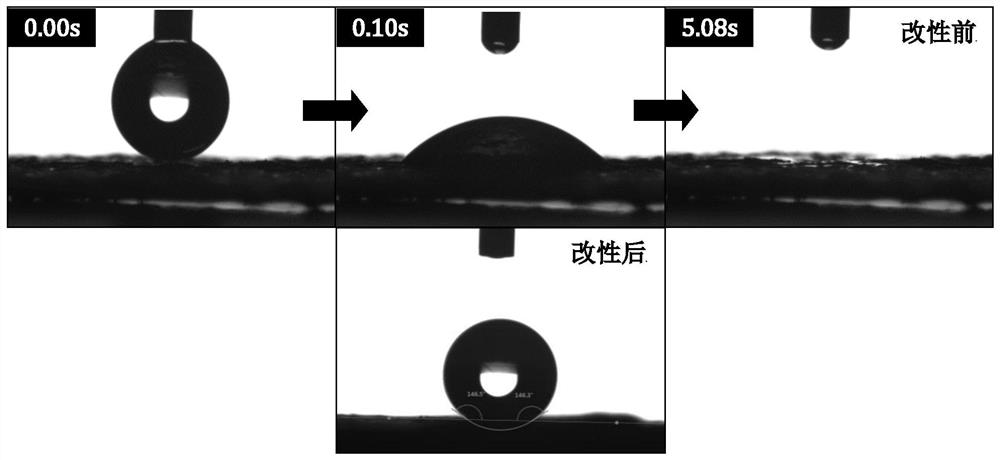

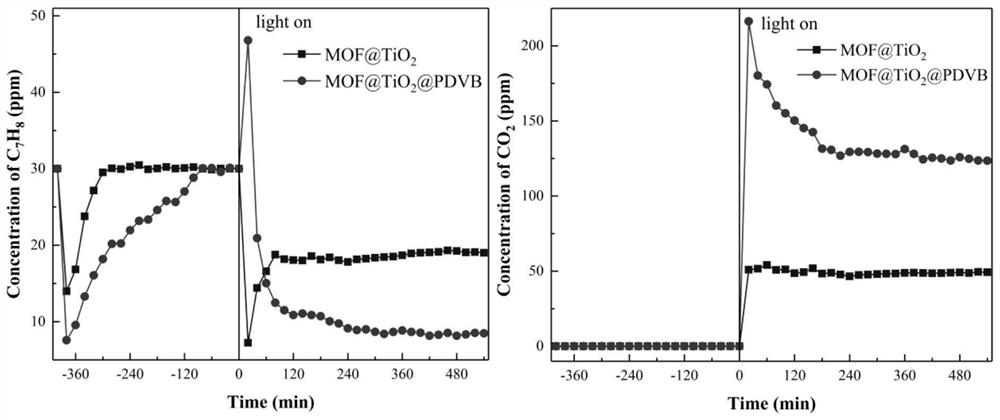

A photocatalyst and reaction kettle technology, applied in physical/chemical process catalysts, organic compound/hydride/coordination complex catalysts, chemical instruments and methods, etc. Hydrophilic, poor photocatalytic activity, etc., to achieve the effect of short cycle, inhibition of deposition on the surface of the material, and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Preparation of PDVB: Mix 2.0g of divinylbenzene and 20mL of tetrahydrofuran to form mixed solution A, stir at room temperature at 25°C for 10min, then add 0.05g of azobisisobutylcyanide to mixed solution A, mix and stir for 240min to obtain mixed solution B , and then transfer B to a polytetrafluoroethylene reactor, then put the liner of the polytetrafluoroethylene reactor into a high-pressure reactor, conduct a hydrothermal reaction at 100°C for 12 hours, and after natural cooling, dissolve the organic solvent at 25°C Volatilization and removal to prepare superhydrophobic material PDVB;

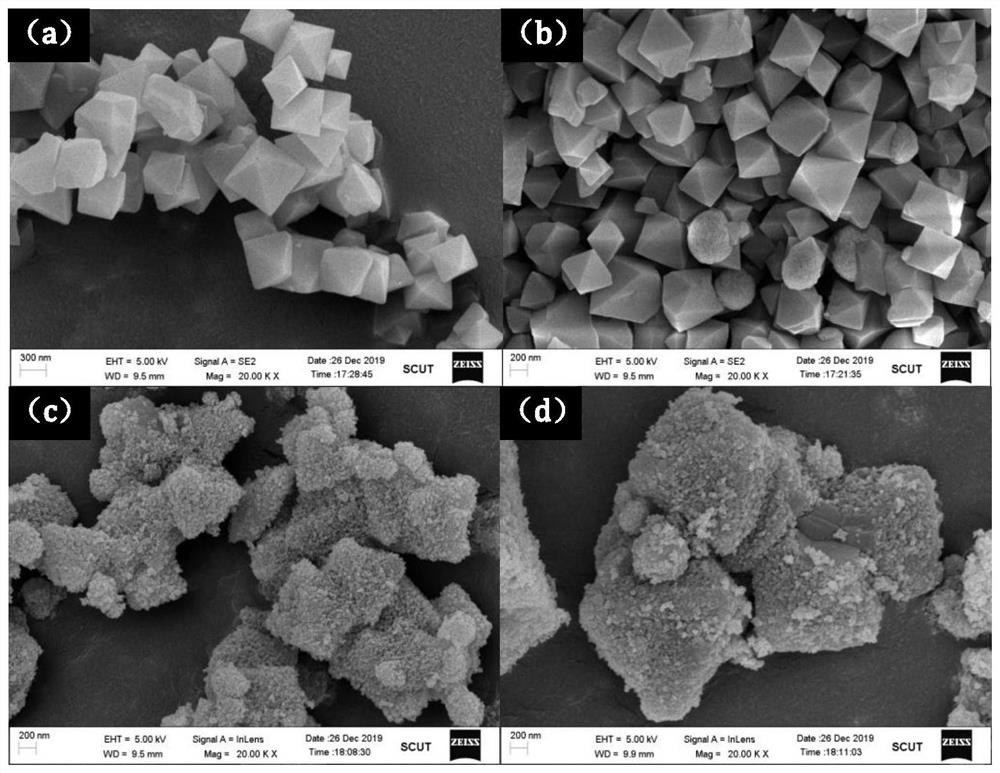

[0033] Preparation of MIL-101: Add 3.2g of chromium nitrate and 1.3g of terephthalic acid into 56mL of deionized water to obtain mixed solution A, stir at room temperature at 25°C for 30min, then add 0.4ml of hydrofluoric acid solution into mixed solution A , mixed and stirred for 30 minutes to obtain a mixed solution B, which was transferred to a polytetrafluoroethylene reactor liner...

Embodiment 2

[0037] Preparation of PDVB: Mix 2.0g of divinylbenzene and 20mL of tetrahydrofuran to form mixed solution A, stir at room temperature at 25°C for 10min, then add 0.05g of azobisisobutylcyanide to mixed solution A, mix and stir for 240min to obtain mixed solution B , and then transfer B to a polytetrafluoroethylene reactor, then put the liner of the polytetrafluoroethylene reactor into a high-pressure reactor, conduct a hydrothermal reaction at 100°C for 12 hours, and after natural cooling, dissolve the organic solvent at 25°C Volatilization and removal to prepare superhydrophobic material PDVB;

[0038] Preparation of MIL-101: Add 3.2g of chromium nitrate and 1.3g of terephthalic acid into 56mL of deionized water to obtain mixed solution A, stir at room temperature at 25°C for 30min, then add 0.4mL of hydrofluoric acid solution into mixed solution A , mixed and stirred for 30 minutes to obtain a mixed solution B, which was transferred to a polytetrafluoroethylene reactor liner...

Embodiment 3

[0042] Preparation of PDVB: Mix 2.0g of divinylbenzene and 20mL of tetrahydrofuran to form mixed solution A, stir at room temperature at 25°C for 10min, then add 0.05g of azobisisobutylcyanide to mixed solution A, mix and stir for 240min to obtain mixed solution B , and then transfer B to a polytetrafluoroethylene reactor, then put the liner of the polytetrafluoroethylene reactor into a high-pressure reactor, conduct a hydrothermal reaction at 100°C for 12 hours, and after natural cooling, dissolve the organic solvent at 25°C Volatilization and removal to prepare superhydrophobic material PDVB;

[0043] Preparation of MIL-101: Add 3.2g of chromium nitrate and 1.3g of terephthalic acid into 56mL of deionized water to obtain mixed solution A, stir at room temperature at 25°C for 30min, then add 0.4ml of hydrofluoric acid solution into mixed solution A , mixed and stirred for 30 minutes to obtain a mixed solution B, which was transferred to a polytetrafluoroethylene reactor liner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com