3D printing method and 3D printing equipment for realizing printing method

A 3D printing and equipment technology, applied in the field of 3D printing, can solve the problems of expensive orthopedic implants, unaffordable families of ordinary patients, and high manufacturing costs, and achieve excellent biological activity, excellent biocompatibility, and low cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

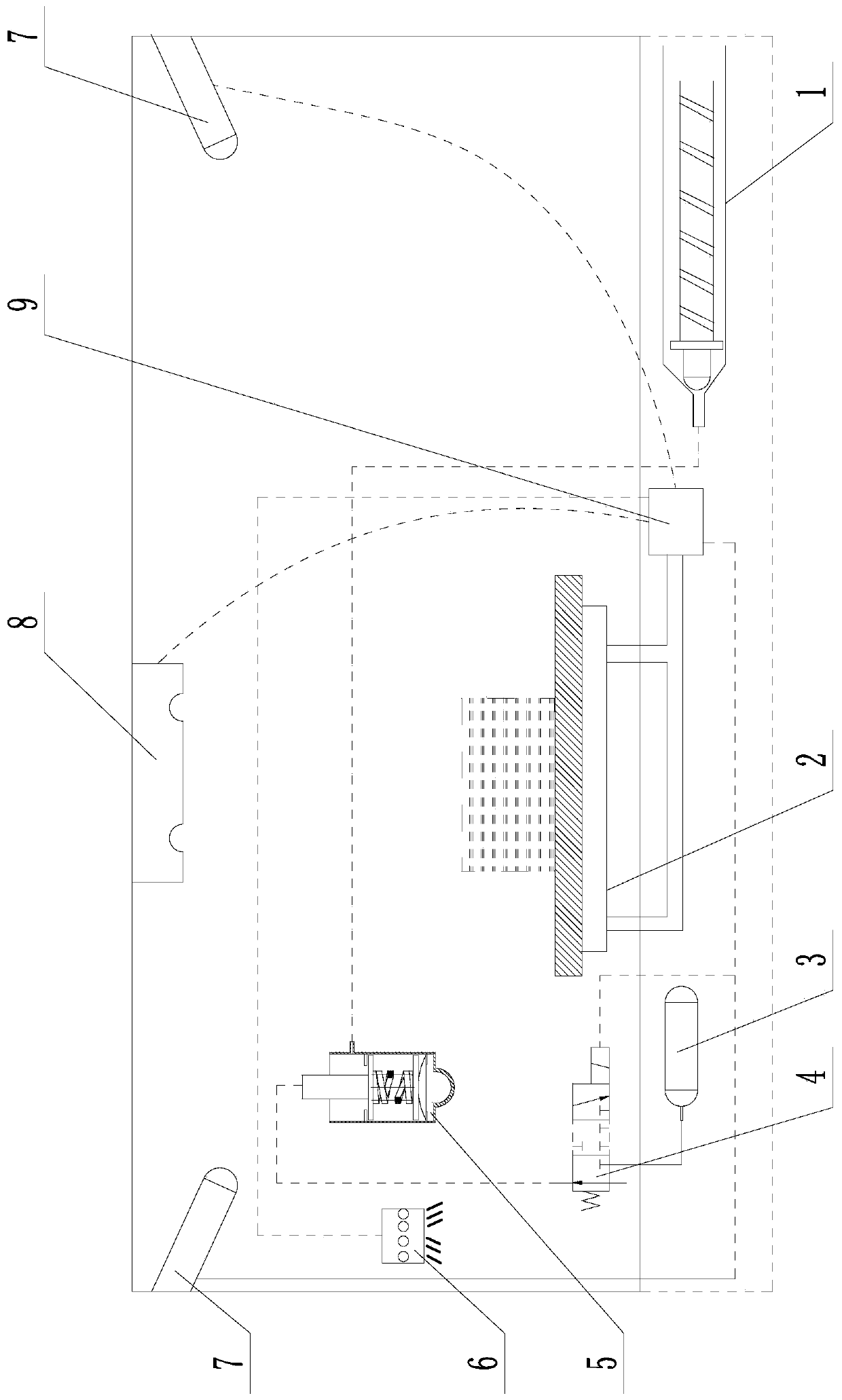

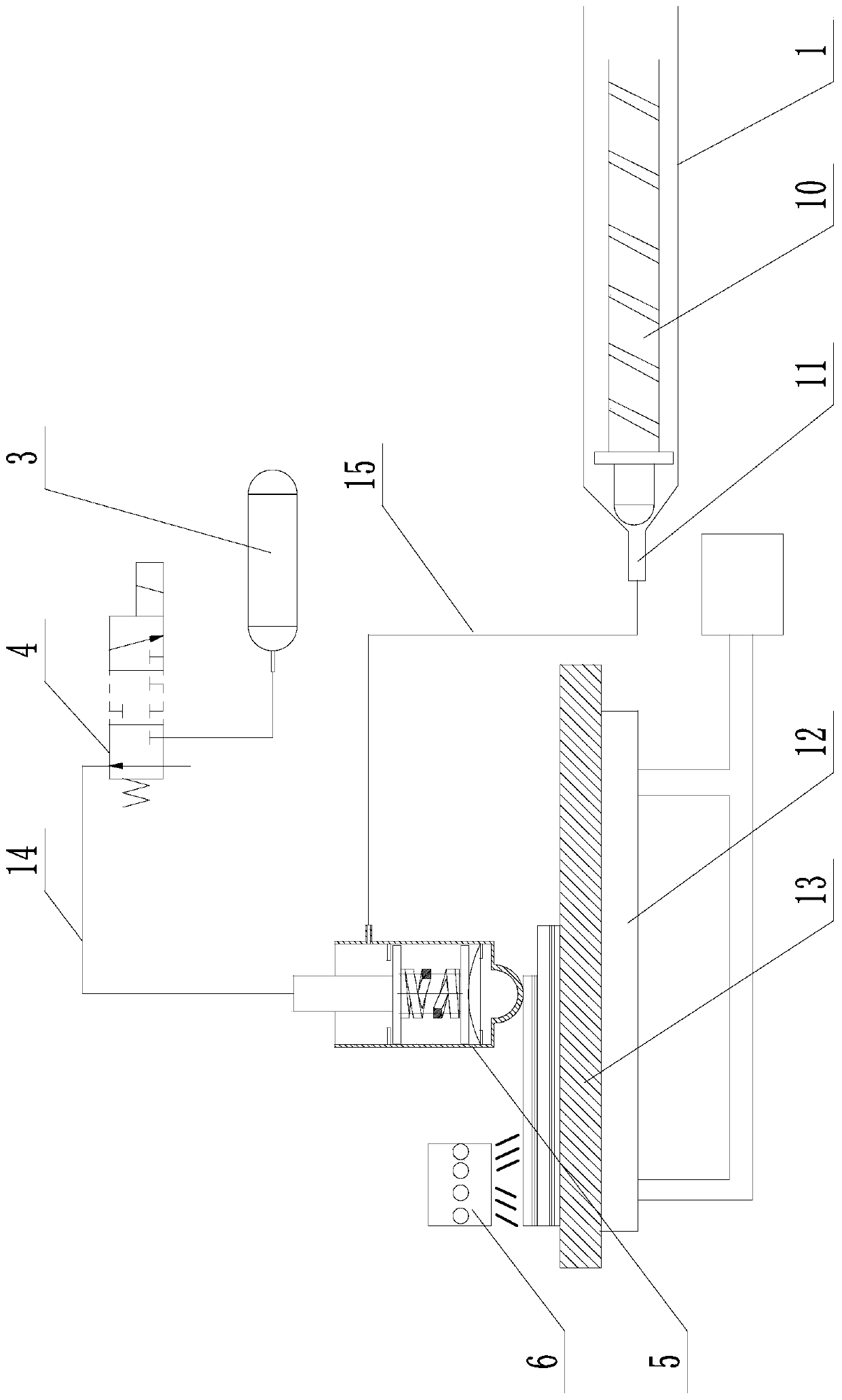

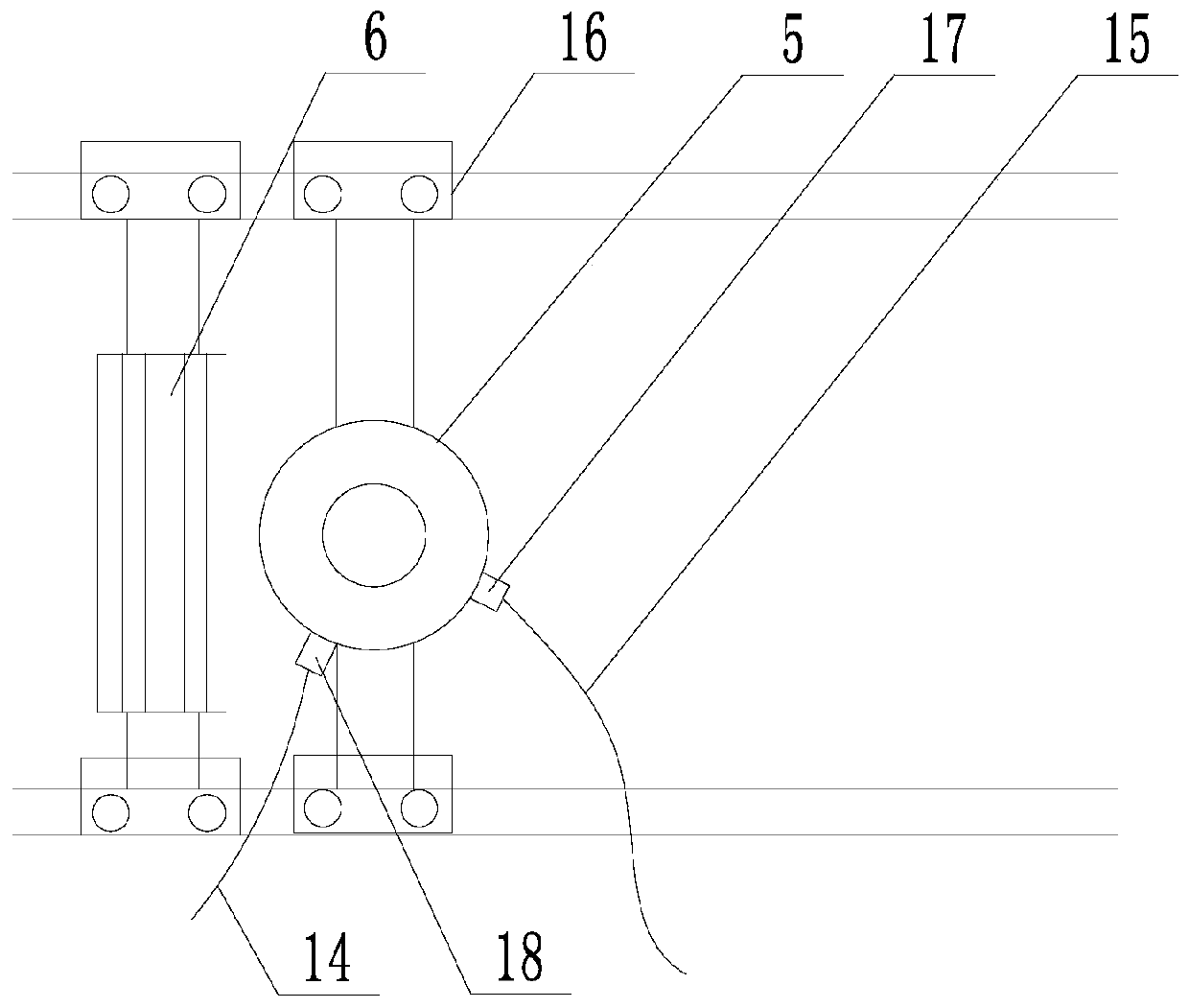

[0044] Embodiments of the present invention are further described below in conjunction with accompanying drawings:

[0045] like Figure 1~4 As shown, the 3D printing equipment for realizing the 3D printing method of the present invention includes a mixing extruder 1, a printing hot bed 2, an infrared heater 6, an ultrasonic flaw detector 7, a three-dimensional data detector 8 and a control system 9; The discharge port 11 of the mixing extruder 1 is connected to the feed port 17 on the printing nozzle 5 through the feeding pipe 15, and the air inlet 18 at the top of the printing nozzle 5 is connected to the air pressure system 3 through the air supply pipeline 14, and the air supply pipe The electromagnetic valve 4 is installed on the road 14; the printing nozzle 5 and the infrared heater 6 are movable; the printing hot bed 2 can be lifted. Among them, the movement of the printing nozzle 5 and the infrared heater 6 can be realized by using the electric track 16 in the convent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com