Synthesis method of secondary alcohol polyoxyethylene ether

A technology of secondary alcohol polyoxyethylene ether and polyoxyethylene ether, which is applied in the field of synthesis of secondary alcohol polyoxyethylene ether, and can solve the problems of small residual amount of secondary alcohol and large residual amount of secondary alcohol

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

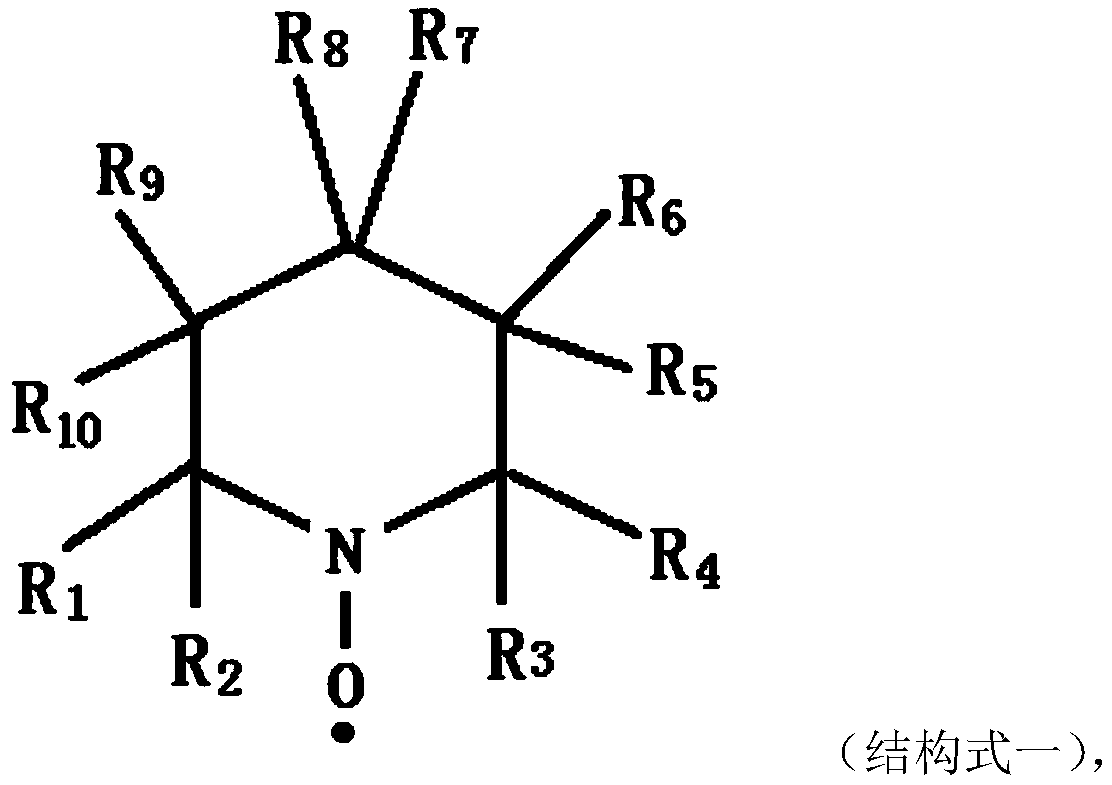

Method used

Image

Examples

Embodiment 1

[0035]Put 200g of secondary tridecyl alcohol and 0.5g of metallocene catalyst into a 1-liter high-pressure reactor with stirring, electric heating jacket and inner water-cooling coil, seal the high-pressure reactor, start stirring, nitrogen replacement three times, at a temperature of 100°C and The pressure of -0.096MPa is evacuated and dehydrated for 30 minutes, then slowly feed ethylene oxide into the reactor kettle, control the reaction temperature at 120°C and the reaction pressure to be 0.20MPa, until the total amount of ethylene oxide fed is 264g, Stop feeding ethylene oxide, then maintain the reaction temperature until the pressure of the reactor no longer drops, indicating that the aging reaction is completed, cool the temperature to 60° C. and add 1 g of lactic acid for neutralization to obtain a secondary alcohol polyoxyethylene (6) ether product.

[0036] The residual secondary alcohol in the product is measured by gas chromatography, and the secondary alcohol residu...

Embodiment 2

[0038] Put 200g of secondary tridecanol and 1g of metallocene catalyst into a 1-liter high-pressure reactor with stirring, electric heating jacket and inner water-cooling coil, seal the high-pressure reactor, start stirring, nitrogen replacement three times, at a temperature of 100°C and - The pressure of 0.096MPa was evacuated and dehydrated for 30 minutes, and then ethylene oxide was slowly passed into the reactor kettle, the reaction temperature was controlled at 120°C and the reaction pressure was 0.20MPa, until the total amount of ethylene oxide was 264g, stop Feed ethylene oxide, and then maintain the reaction temperature until the pressure of the reactor no longer drops, indicating that the aging reaction is complete, cool the temperature to 60° C. and add 1 g of lactic acid for neutralization to obtain a secondary alcohol polyoxyethylene (6) ether product.

[0039] The residual secondary alcohol in the product is measured by gas chromatography, and the secondary alcohol...

Embodiment 3

[0041] Put 200g of secondary tridecyl alcohol and 1.5g of metallocene catalyst into a 1-liter high-pressure reactor with stirring, electric heating jacket and inner water-cooling coil, seal the high-pressure reactor, start stirring, nitrogen replacement three times, at a temperature of 100°C and The pressure of -0.096MPa is evacuated and dehydrated for 30 minutes, then slowly feed ethylene oxide into the reactor kettle, control the reaction temperature at 120°C and the reaction pressure to be 0.20MPa, until the total amount of ethylene oxide fed is 264g, Stop feeding ethylene oxide, then maintain the reaction temperature until the pressure of the reactor no longer drops, indicating that the aging reaction is completed, cool the temperature to 60° C. and add 1 g of lactic acid for neutralization to obtain a secondary alcohol polyoxyethylene (6) ether product.

[0042] The residual secondary alcohol in the product is measured by gas chromatography, and the secondary alcohol resid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com