Papermaking waste residue harmless treatment process

A technology of harmless treatment and papermaking waste residue, which is applied in the direction of incinerators, waste fuel, petroleum industry, etc., can solve the problems of inconvenient disassembly, limited degree of waste gas purification, and shortage of papermaking raw materials, so as to facilitate free disassembly, improve purification efficiency, The effect of increasing the success rate of ignition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

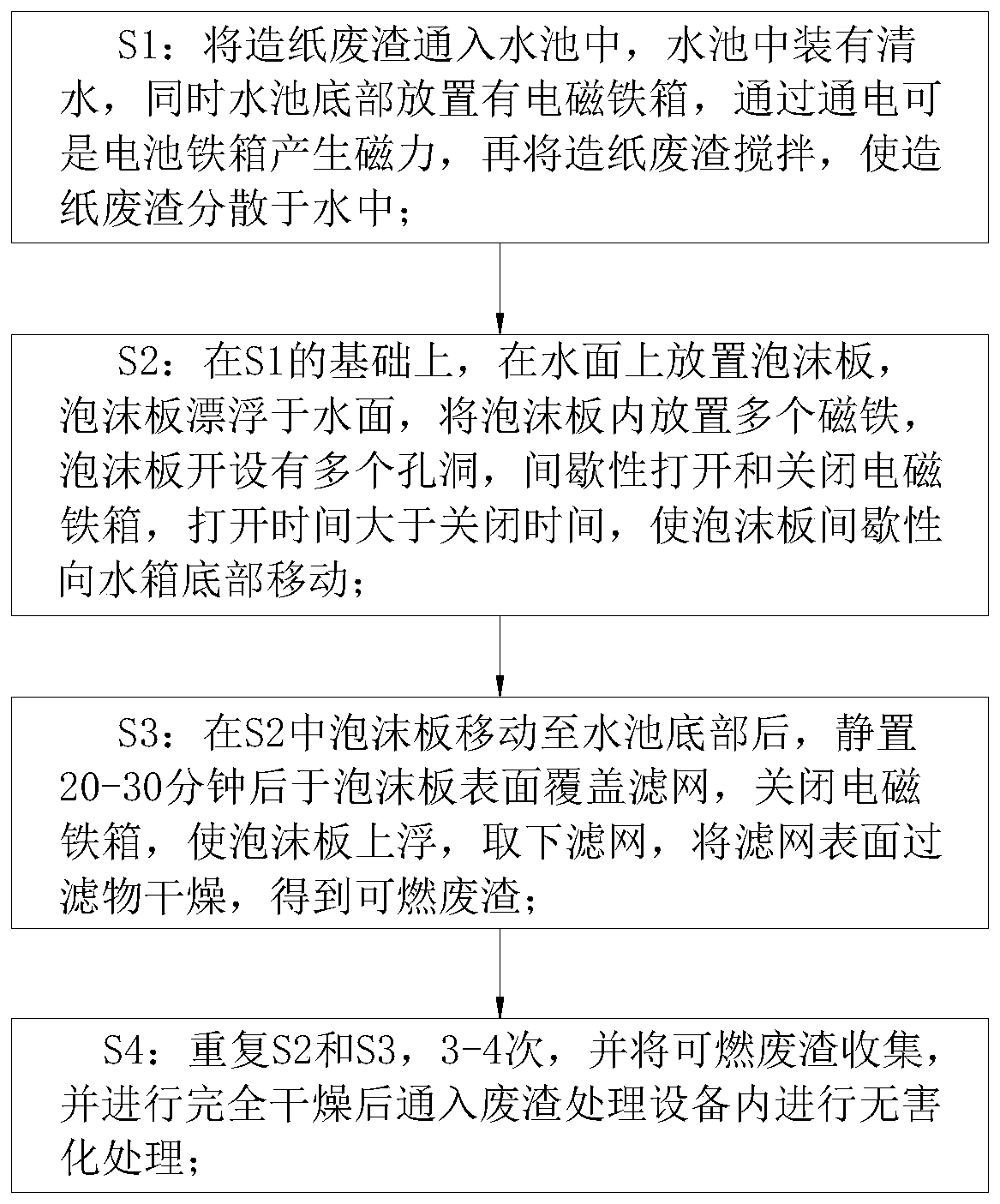

Method used

Image

Examples

Embodiment approach

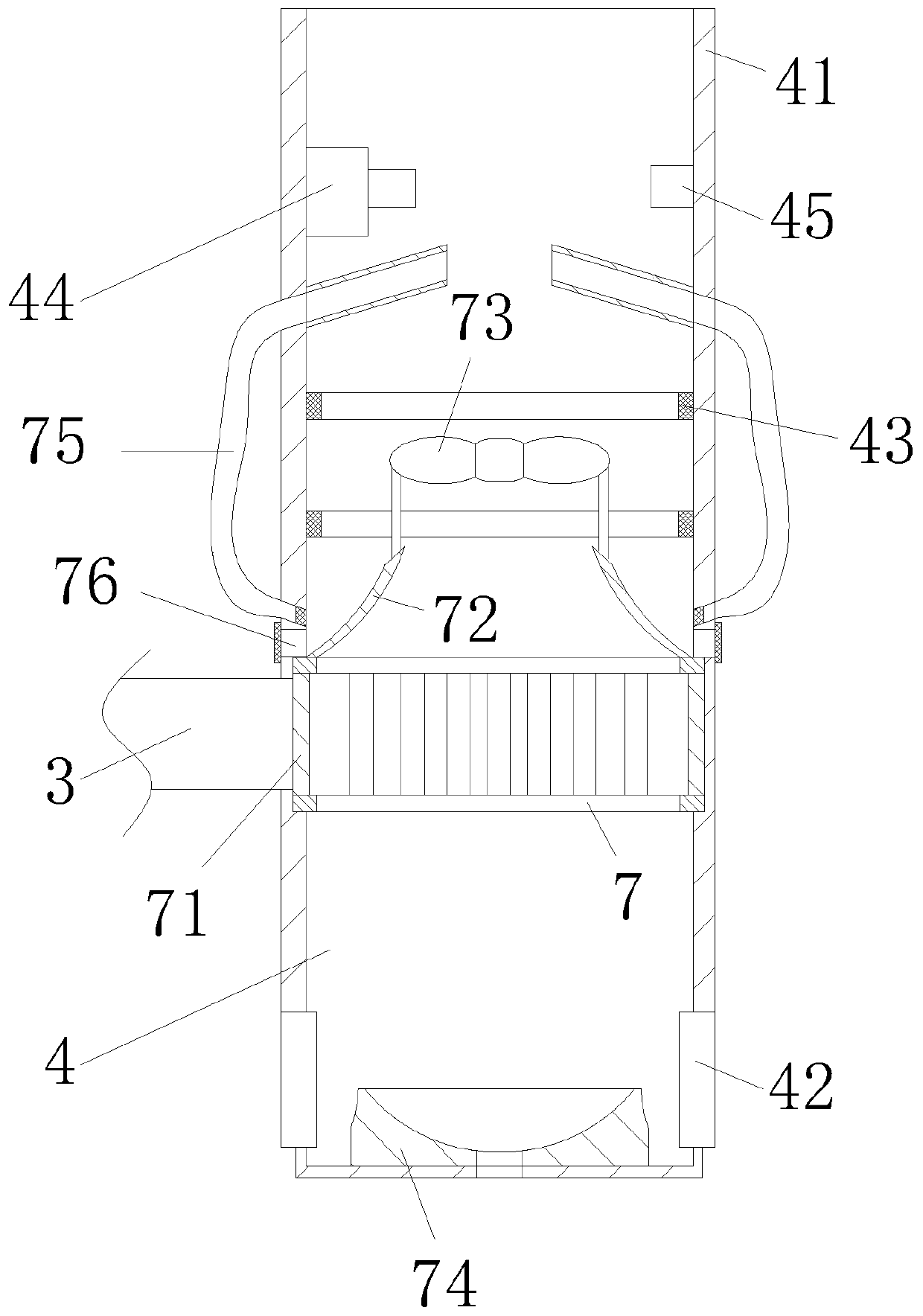

[0036] As an embodiment of the present invention, the outer cylinder wall 41 is provided with a chute on the inner wall where the exhaust pipe 3 communicates; two swivel rings 7 are slidably connected in the chute; the two swivel rings 7 are fixedly connected There is a uniformly arranged power plate 71; the power plate 71 is designed to be inclined; the upper surface of the swivel 7 above is fixedly connected with a drive ring 72; the drive ring 72 is designed to be inclined, and the upper end of the drive ring 72 passes through a uniformly arranged fixed rod Be fixedly connected with impeller 73, described impeller 73 is positioned between two hygroscopic cottons 43; Air, so that the airflow flows downward; the bottom of the outer cylinder wall 41 is fixedly connected with an ash accumulation box 74; the ash accumulation box 74 is designed in a bowl shape, and the bottom of the ash accumulation box 74 is connected to the outer design of the outer cylinder wall 41; , the exha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com