Environment-friendly metal surface treatment device

A kind of metal surface treatment and environment-friendly technology, applied in the direction of metal material coating process, coating, hot-dip plating process, etc., to achieve the effect of avoiding fracture, increasing practicability, and increasing service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

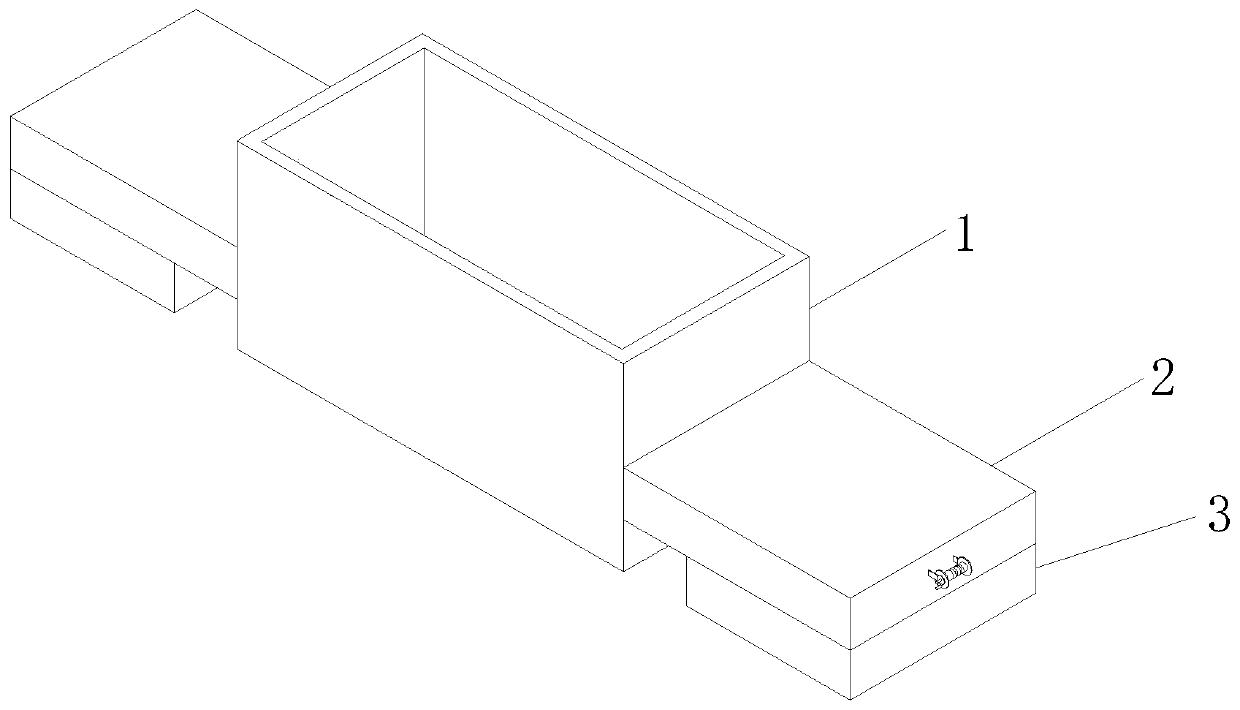

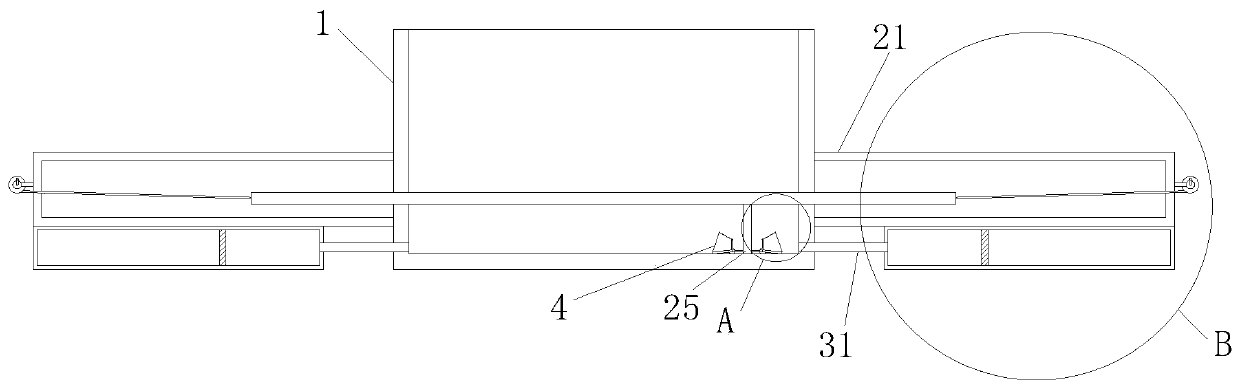

[0030] Example 1: Please refer to Figure 1-2 , an environment-friendly metal surface treatment device, including a galvanized box 1, the left and right sides of the galvanized box 1 are symmetrically provided with the same partition cleaning device 2, and a filter discharge device 3 is provided below the two partition cleaning devices 2, The partition cleaning device 2 is located at the horizontal position in the middle section of the galvanized box body 1, the filter discharge device 3 is located on the same level as the bottom surface of the galvanized box body 1, and the filter discharge device 3 is fixedly connected with the galvanized box body 1, and the partition cleaning device 2 is located at The part inside the galvanized box body 1 is provided with a cleaning mechanism 4 .

Embodiment 2

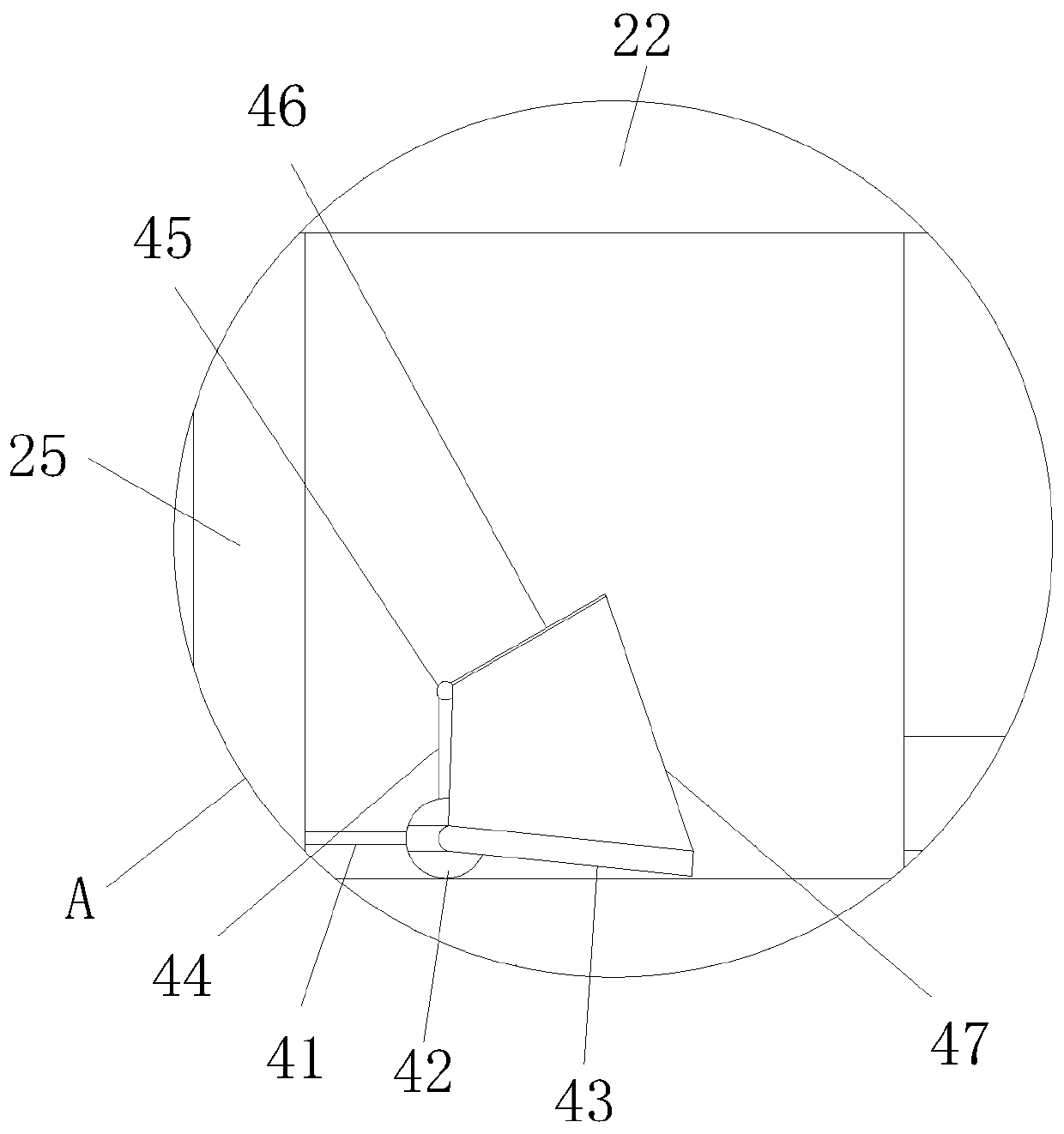

[0031] Embodiment 2: On the basis of Embodiment 1, please refer to figure 2 and Figure 4, the partition cleaning device 2 includes a movement plate 22, the length of the movement plate 22 is 2.2 times the length of the galvanized box body 1, and the movement plate 22 is arranged horizontally through the galvanized box body 1, and the front and rear ends of the movement plate 22 Located in the front and rear walls of the galvanized box 1, that is, the moving plate 22 can completely separate the interior of the galvanized box 1 into upper and lower parts.

Embodiment 3

[0032] Embodiment three: on the basis of embodiment two, please refer to figure 2 and Figure 4 , the partition cleaning device 2 also includes a movement accommodation frame 21, the movement accommodation frame 21 is located at the position where the left and right ends of the movement plate 22 protrude from the galvanized box body 1, and the movement accommodation frame 21 is fixedly connected to the outer wall of the galvanized box body 1, The side wall of the motion storage frame 21 far away from the galvanized box body 1 is provided with a winding shaft 23, and the winding shaft 23 is fixedly connected with the side wall of the motion storage frame 21 through a connecting rod, and the motion plate 22 is fixedly installed and connected with the side wall away from the galvanized box body 1. Belt 24, the other end of the connection belt 24 runs through the side wall of the motion storage frame 21 and is fixedly connected to the winding shaft 23, and the left and right side...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap