Pure titanium implant provided with cobalt-doped coating and preparation method of pure titanium implant

A technology of implants and pure titanium, which is applied in coatings, prostheses, pharmaceutical formulations, etc., can solve the problems of insufficient osseointegration on the surface of implants, and achieve the effects of preventing inflammation, uniform coating thickness, and promoting differentiation and proliferation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The invention provides a method for preparing a pure titanium implant with a cobalt-doped coating, comprising the following steps:

[0025] (1) The surface of the pure titanium implant is sequentially polished, sandblasted, cleaned and dried to obtain a pretreated pure titanium implant;

[0026] (2) acid-etching the surface of the pretreated pure titanium implant to obtain an acid-etched pure titanium implant;

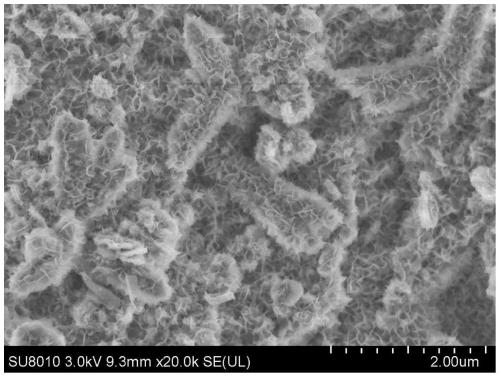

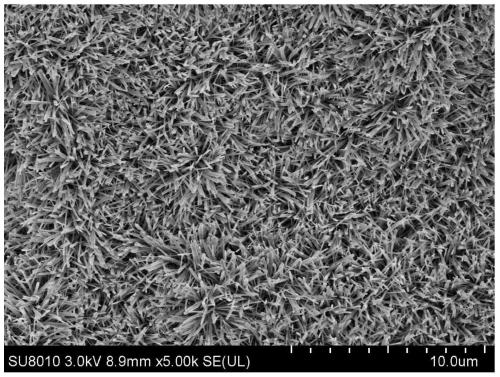

[0027] (3) Using the acid-etched pure titanium implant as the cathode, a two-electrode system is used for electrochemical deposition in a cobalt-containing electrolyte, and a cobalt-doped coating is formed on the surface of the pure titanium implant to obtain a pure titanium implant with a cobalt-doped coating body; the cobalt-containing electrolyte consists of CaCl 2 , NH 4 h 2 PO 4 , NaCl, CoCl 2 Prepared with water raw materials.

[0028] In the present invention, the surface of the pure titanium implant is sequentially polished, sand blasted, cleaned a...

Embodiment 1

[0044] (1) The pure titanium sheet is polished with sandpaper of 320 mesh, 600 mesh, 800 mesh, and 1000 mesh in order from small to large. After the grinding is smooth and uniform, the large particle emery is used for sandblasting under the pressure of 4MPa until the surface of the titanium sheet is uniform. No obvious reflection; ultrasonically clean the sandblasted titanium sheet in acetone solution for 15 minutes, repeat 3 times, then ultrasonically clean in 75% ethanol and deionized water for 15 minutes each, and dry in an oven;

[0045] (2) Use 0.09mol / L nitric acid, 0.11mol / L hydrofluoric acid and distilled water to prepare the first acid etching solution (4:2:1000 by volume), and immerse the completely dried in step (1). The surface of the titanium sheet is placed at room temperature for the first acid etching for 10 minutes. After the specified reaction time is reached, the solution in the glass dish is discarded, and the surface of the titanium sheet is rinsed with a l...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap