Installation and construction method of grinding roller base of raw material grinding mill

A construction method and roller grinding technology, which can be applied in basic structure engineering, construction, etc., can solve problems such as base deviation, hollowing, and inability to flow grouting materials, and achieve the effects of increased fluidity, convenient operation, and strong applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

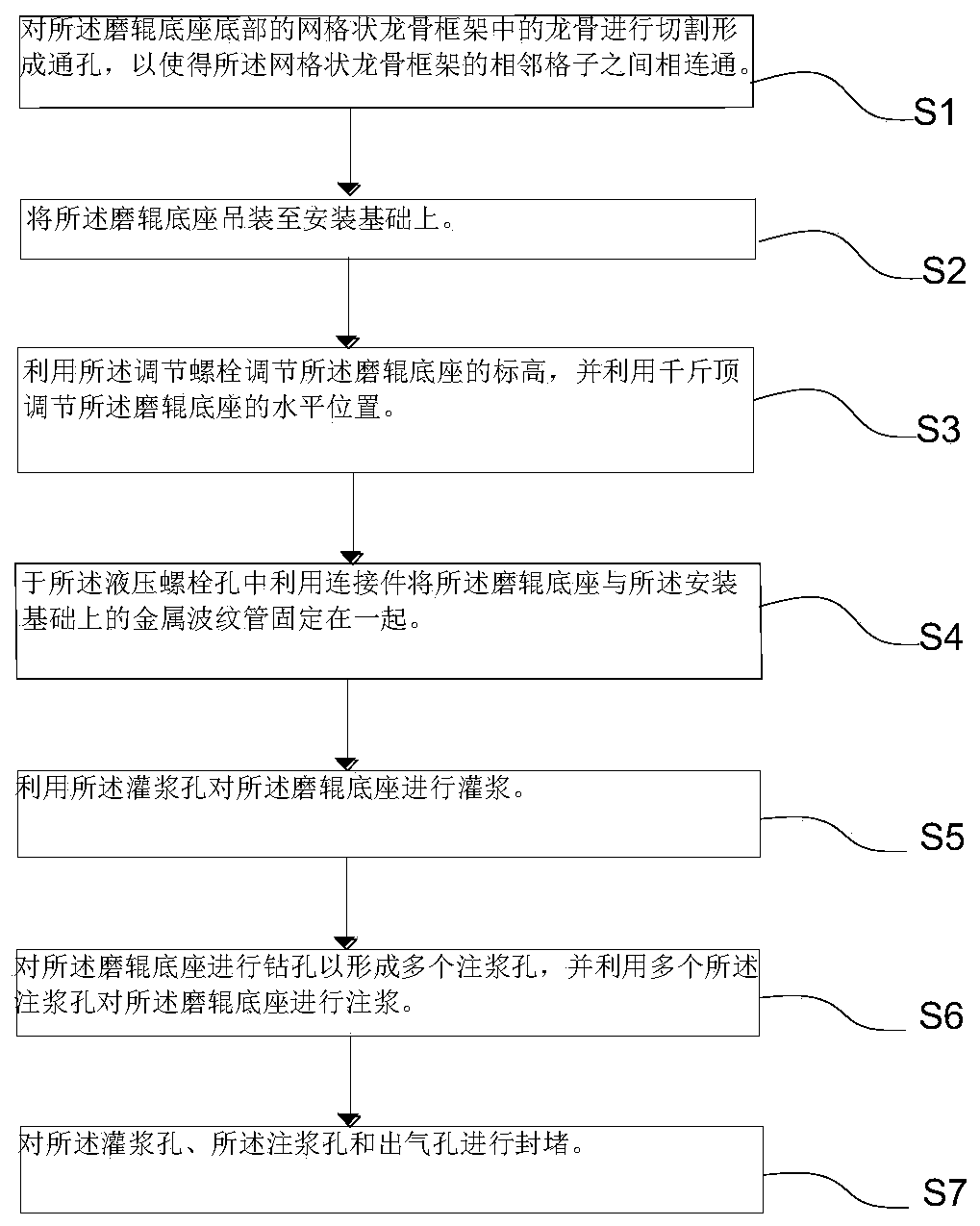

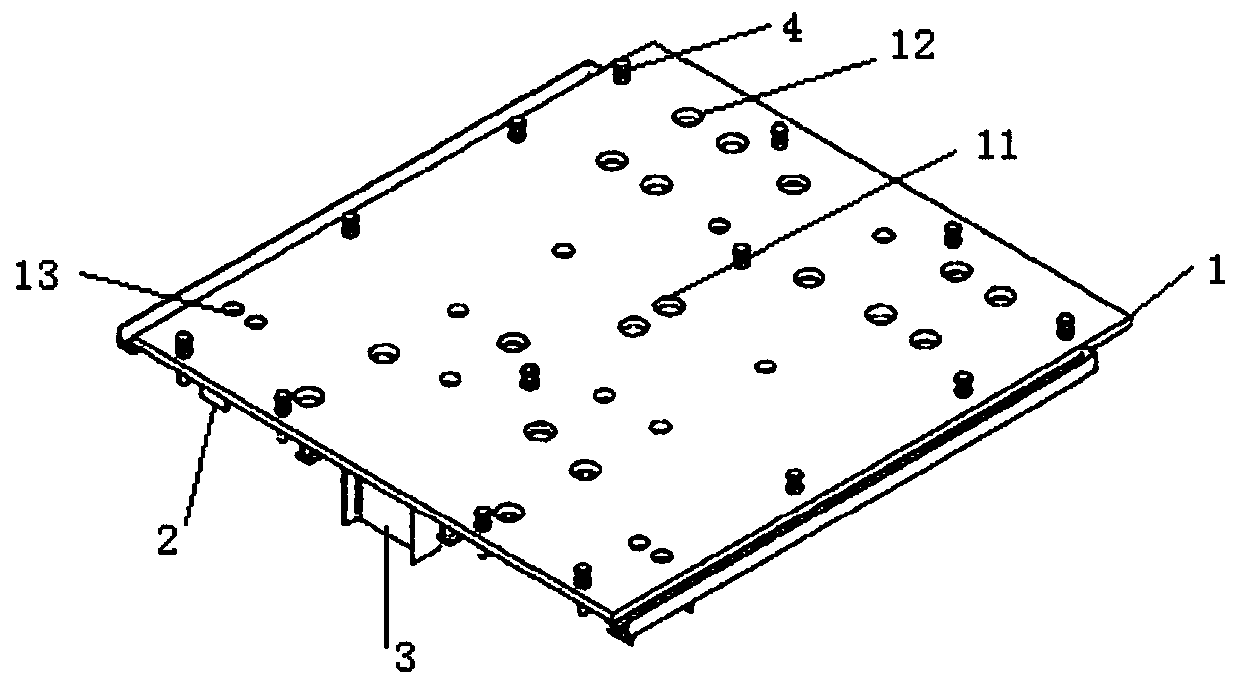

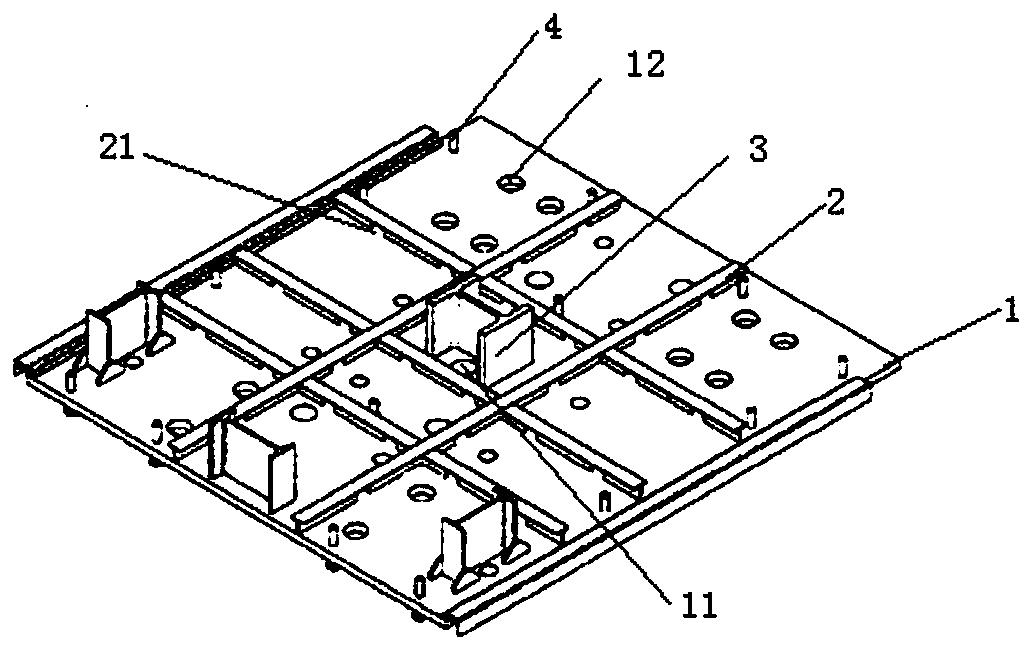

[0030] Such as Figure 1~6 As shown, the present invention discloses a method for installing and constructing a raw material grinding roller base. The grinding roller base includes a bottom plate 1 and a grid-shaped keel frame 2 fixed on the bottom of the bottom plate 1, and the bottom plate 1 is provided with adjusting bolts 4 , hydraulic bolt holes 12, air outlet holes 13 and grouting holes 11, specifically, the method comprises the following steps:

[0031] Step S1, cutting the keels in the grid-shaped keel frame 2 at the bottom of the grinding roller base to form cutting holes 21, so that adjacent grids of the grid-shaped keel frame 2 are connected.

[0032] In the embodiment of the present invention, after the cutting holes 21 are formed, iron wires are passed through the cutting holes 21 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com