Assembled self-resetting energy dissipation shear wall

A self-resetting and shear wall technology, applied to walls, protective buildings/shelters, buildings, etc., can solve the problems of difficult to effectively ensure structural safety, self-resetting and poor energy consumption performance, and achieve good self-resetting Excellent performance, strong energy consumption and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

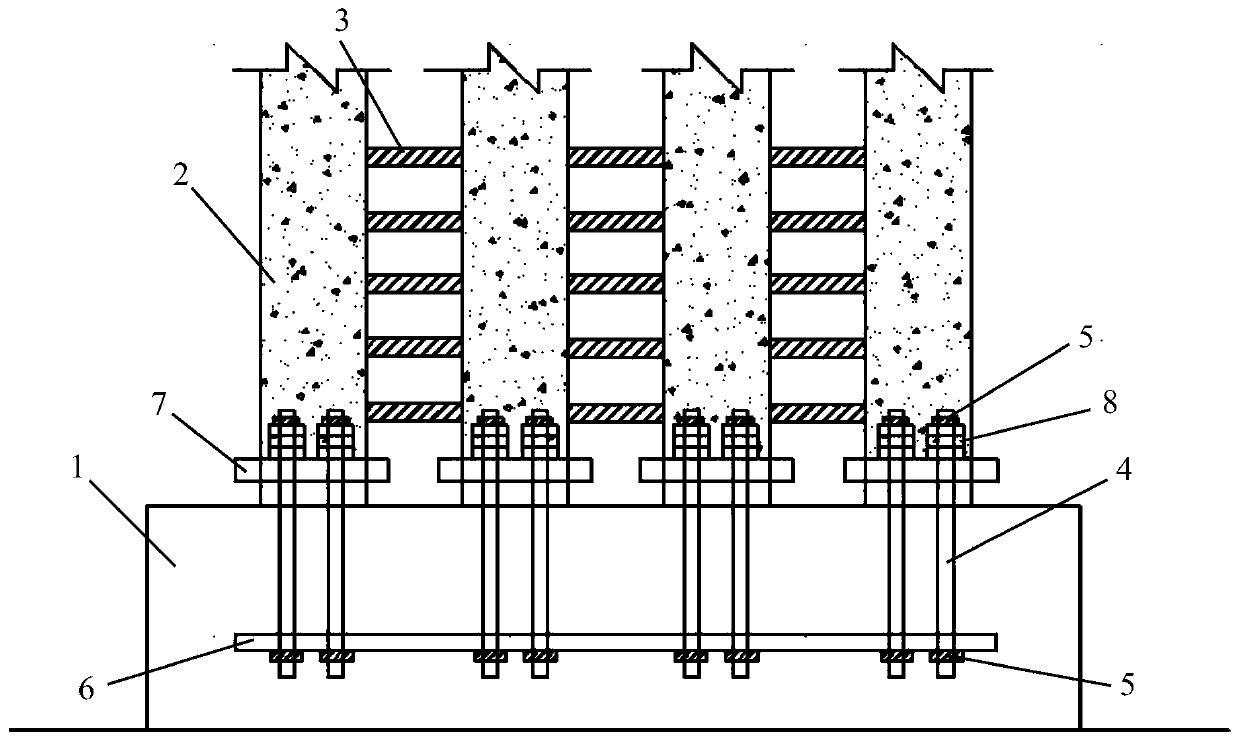

[0052] See attached Figure 8 , the embodiment of the present invention discloses an assembled self-resetting energy-dissipating shear wall, including: a foundation 1, a steel tube concrete column 2, a damper 3, a high-strength anchor rod 4 and a nut 5;

[0053] The foundation 1 is pre-embedded and fixed with a pre-embedded steel plate 6;

[0054] The number of concrete-filled steel tube columns 2 is multiple, and they are arranged at intervals on the top surface of the foundation 1, and each concrete-filled steel tube column 2 is composed of multiple sections; cantilevered plate 7;

[0055] There are multiple dampers 3, and they are fixed between two adjacent concrete-filled steel tube columns 2;

[0056] The number of high-strength anchor rods 4 is multiple, and the top of each high-strength anchor rod 4 passes through the cantilever plate 7, and is equipped with a disc spring group 8, and the bottom end is inserted into the interior of the foundation 1 and passes through th...

Embodiment 2

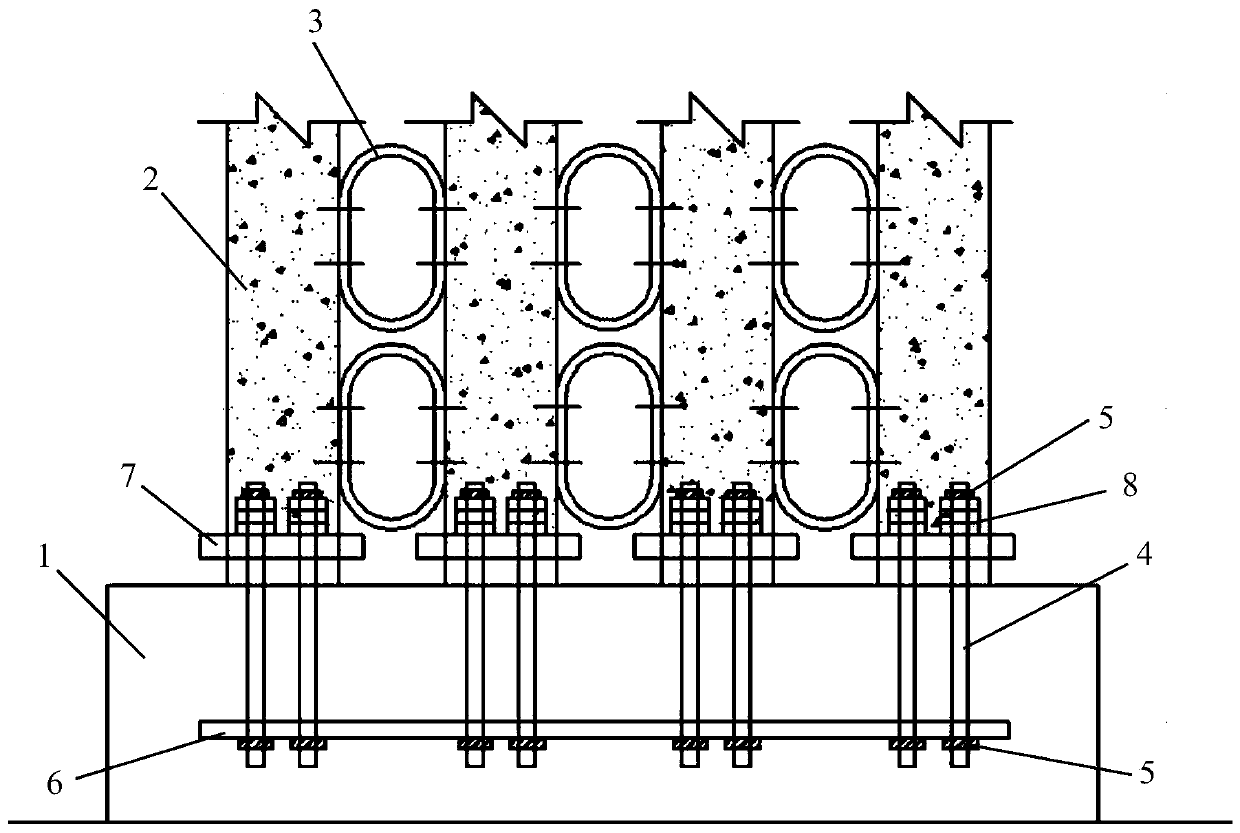

[0068] See attached Figure 9 And attached Figure 10 The difference between this embodiment and Embodiment 1 is that: the bottom surface of the steel pipe concrete column 2 and the top surface of the foundation 1 are connected by a hinge member 9, and a zigzag hinge connection is formed between the hinge member 9 and the top surface of the foundation 1 form. The self-resetting performance of the structure is improved.

[0069] Other structures and principles of this embodiment are the same as those of Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com