A method for automatic control of thermoelectric load

A load and thermoelectric technology, which is applied in the direction of engine components, machines/engines, steam engine devices, etc., can solve the problems of inability to coordinate thermoelectric loads and uneven adjustment effects, so as to improve the level of automation, safety and stability, and the adjustment process is safe and reliable , good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to further illustrate the technical solution of the present invention, the present invention will be further described below through examples.

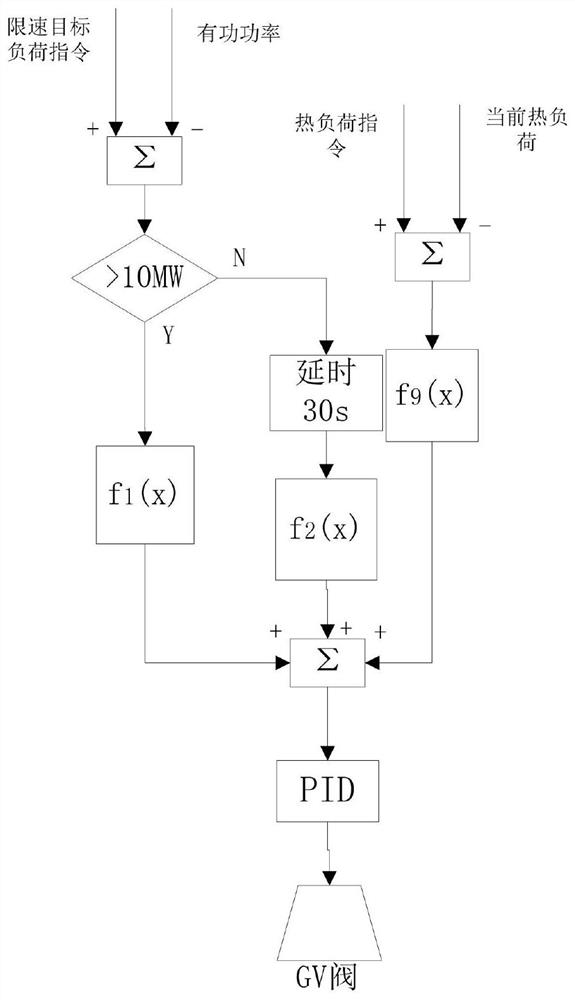

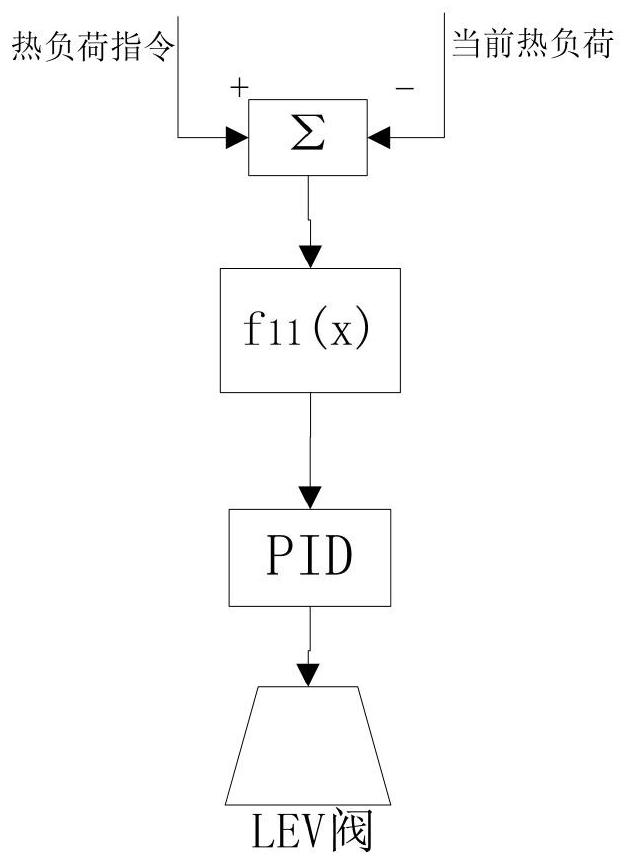

[0025] A method for automatic control of thermoelectric loads, comprising the following steps:

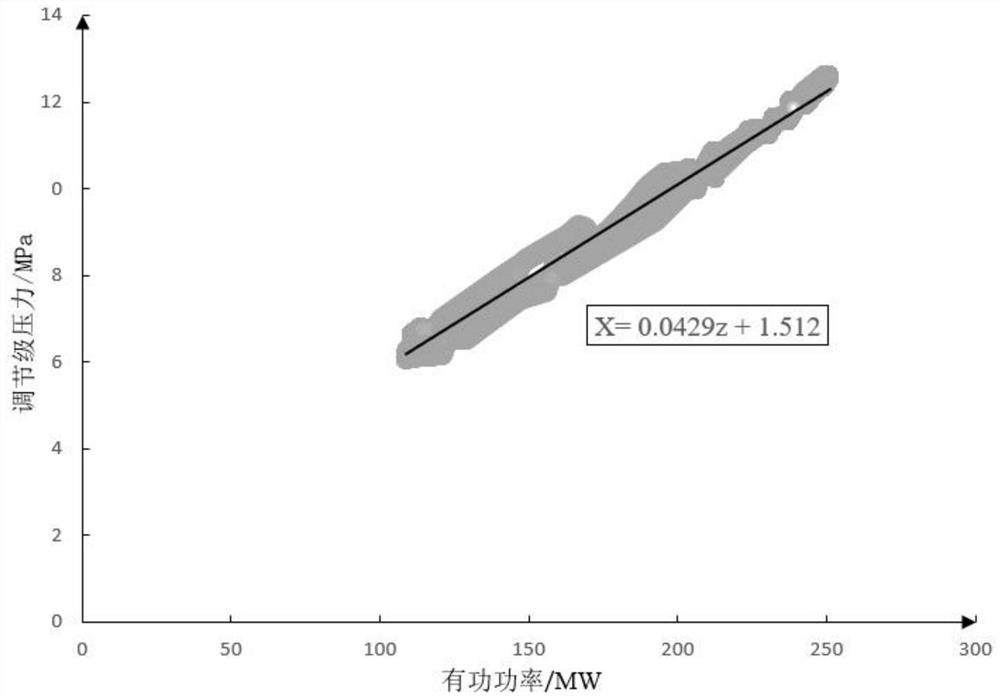

[0026] 1) The function fits the upper and lower limits of the exhaust pressure of the intermediate pressure cylinder and the relationship between the optimal exhaust pressure of the intermediate pressure cylinder and the active power; specifically: according to the operating data of the historical electric load and the pressure of the regulating stage, the active power and the regulating The relationship between the stage pressure; according to the function relationship between the given regulating stage pressure, the upper and lower limits of the exhaust pressure of the intermediate pressure cylinder, and the optimal exhaust pressure of the intermediate pressure cylinder, the active power and the upper and lower limits of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com