Method for manually adjusting static hydraulic balance of centralized heating pipe network based on impedance

A technology of hydraulic balance and manual adjustment, applied in space heating and ventilation details, heating methods, household heating, etc., can solve problems such as limitations, complicated calculation process, and inability to adapt to large systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0069] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

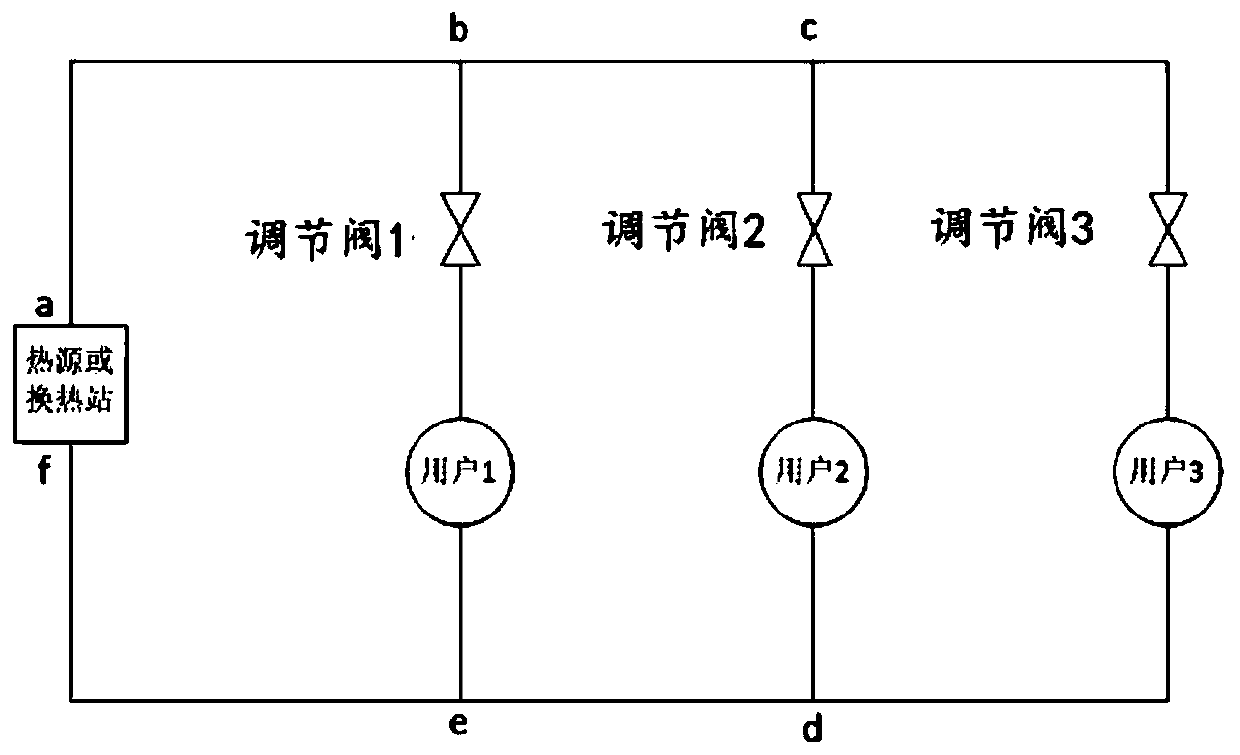

[0070] figure 1 In the illustrated embodiment, there are three users, and user 3 is the most unfavorable user. When using the method of the present invention to manually adjust the static hydraulic balance of the central heating pipe network of the embodiment, firstly, a continuous flow channel is set on each user's branch pipeline. Adjust the opening of the static balance regulating valve, the specific adjustment method is:

[0071] The first step: the configuration of the static balance regulating valve and the calibration of its performance parameters

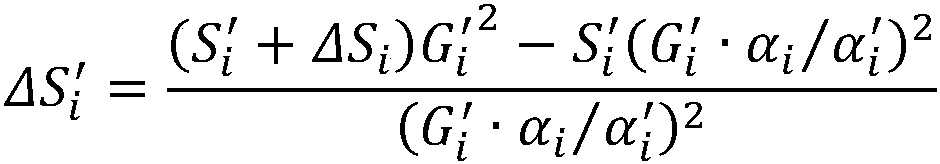

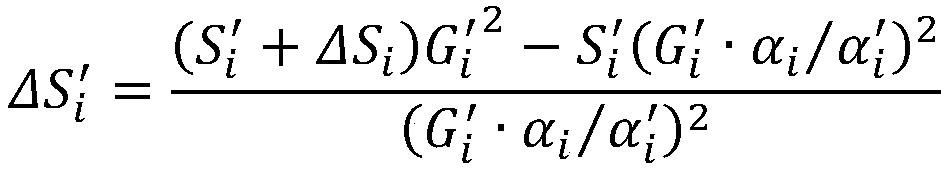

[0072] According to the method introduced in the first step of the technical plan, static balance co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com