Monitoring system and online monitoring method for working state of engine bearing

A monitoring system and working state technology, applied in the direction of mechanical bearing testing, mechanical component testing, machine/structural component testing, etc., can solve unfavorable bearing fault monitoring and life prediction, it is difficult to accurately grasp the actual situation of the engine, flight safety Hidden dangers and other problems to achieve the effect of improving monitoring accuracy, small quality, and ensuring normal operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

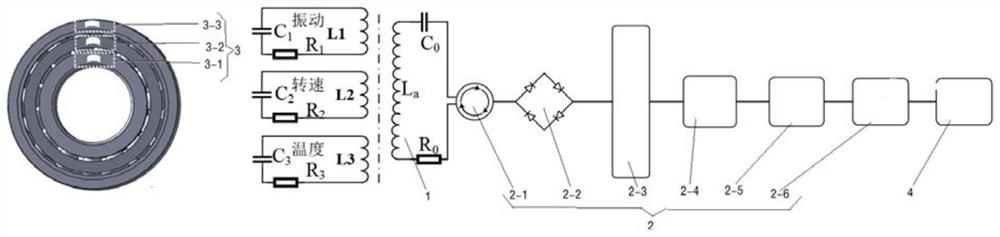

[0042] This embodiment provides a monitoring system for real-time monitoring of the working state of the engine bearing, such as figure 1 As shown, the monitoring system includes a reading antenna 1 , a signal conditioning circuit 2 , and a sensor group 3 .

[0043] Among them, such as figure 1 As shown, the sensor group 3 includes a plurality of passive MEMS sensors with different structures. Specifically, the passive MEMS sensors include a passive MEMS temperature sensor 3-1, a passive MEMS rotational speed sensor 3-2, and a passive MEMS vibration sensor 3- 3. The passive MEMS temperature sensor 3-1 is set on the inner ring of the bearing to measure the temperature data on the surface of the inner ring of the bearing; the passive MEMS speed sensor is set on the cage to measure the speed data of the cage; passive The MEMS vibration sensor is arranged on the outer ring of the bearing to measure the vibration data of the outer ring of the bearing.

[0044] Further, since each...

Embodiment 2

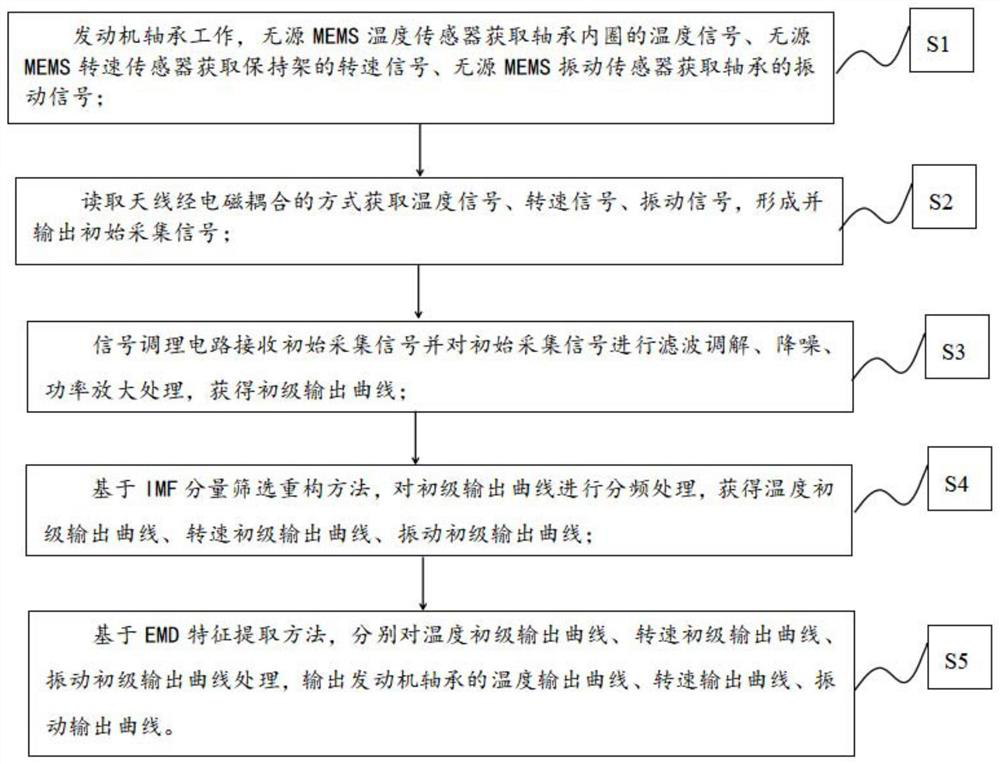

[0055] This embodiment provides an online monitoring method for the working state of the engine bearing. The monitoring system in Embodiment 1 is used to detect the rotational speed, temperature and vibration parameters of the engine bearing, such as figure 2 As shown, the online monitoring method includes the following steps:

[0056] S1. The engine bearing works, the passive MEMS temperature sensor obtains the temperature signal of the inner ring of the bearing, the passive MEMS speed sensor obtains the speed signal of the cage, and the passive MEMS vibration sensor obtains the vibration signal of the bearing.

[0057]Specifically, the passive MEMS temperature sensor is fixed on the surface of the bearing inner ring through the sputtering process, and the temperature signal of the bearing inner ring can be obtained in real time through its Au functional layer; the passive MEMS speed sensor is set on the cage through the sputtering process, The speed signal of the cage can b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com