Double-channel in-situ infrared reaction tank

An in-situ infrared and reaction cell technology, which is applied in the direction of material analysis, instruments, and measuring devices through optical means, can solve problems such as the inability to take into account the interface species of liquid phase species, and the inability to achieve absolute in-situ analysis, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

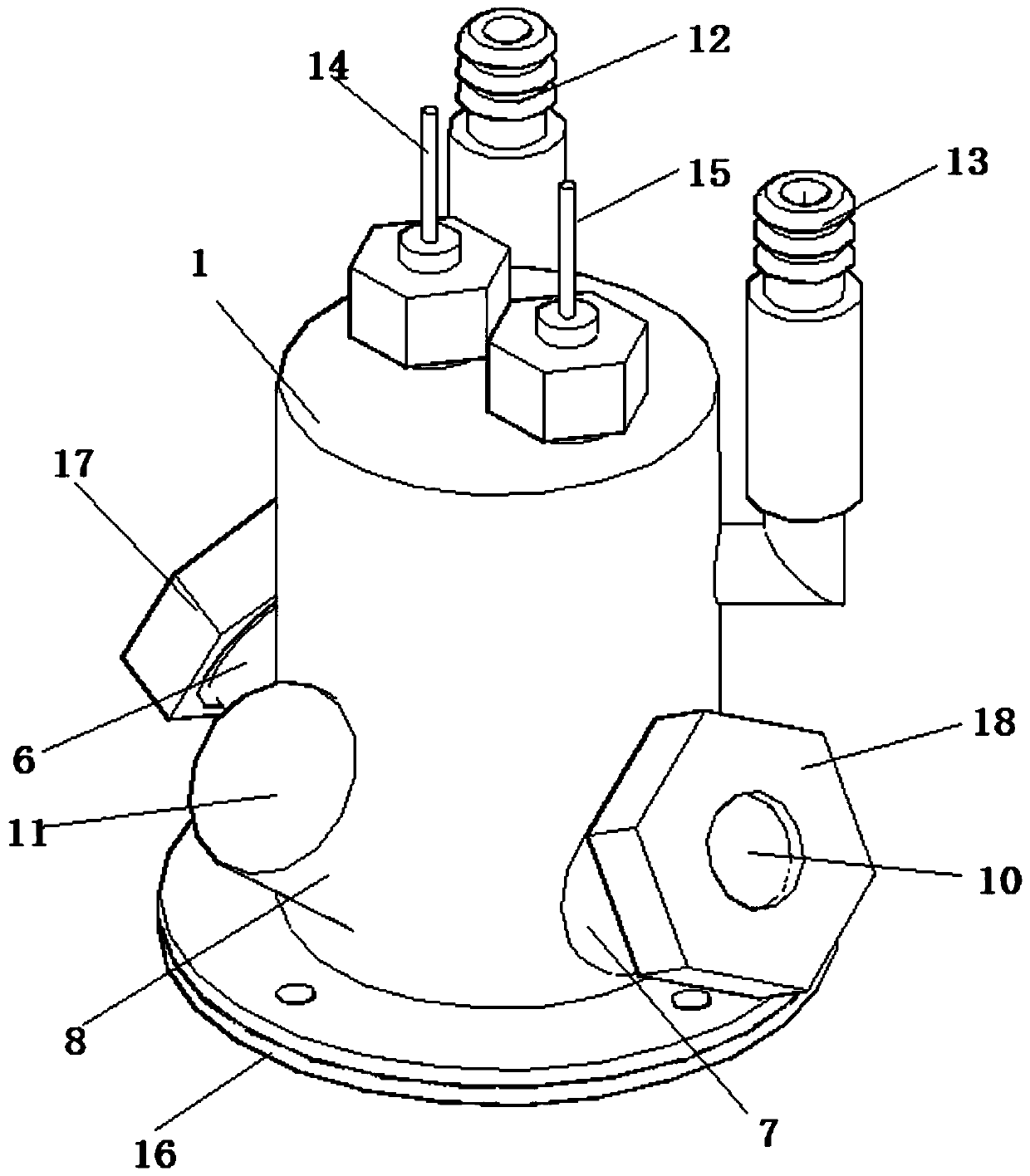

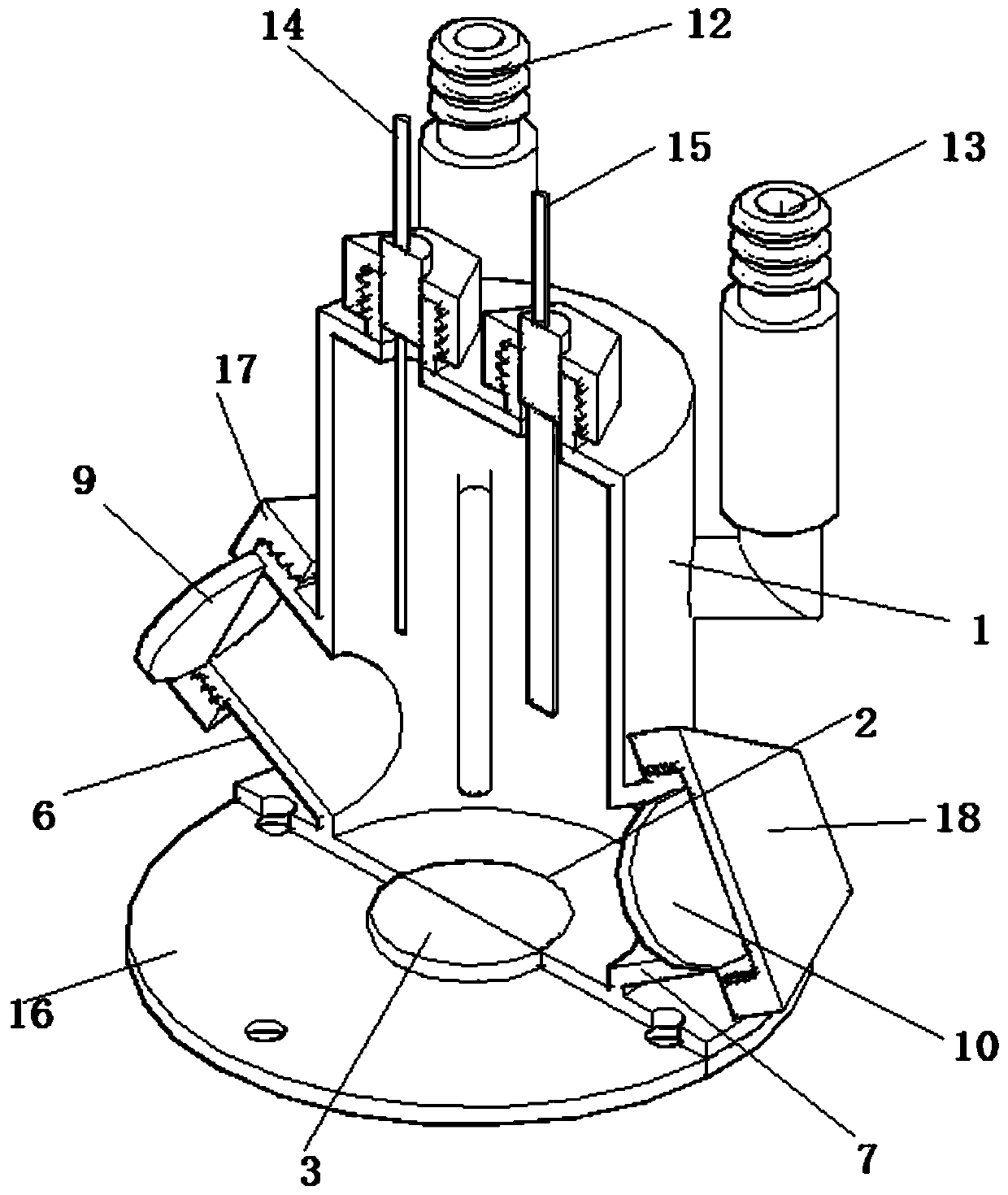

[0020] Reference Figure 1-Figure 4 , The present invention proposes a dual-channel in-situ infrared reaction cell, including a cell body 1; wherein:

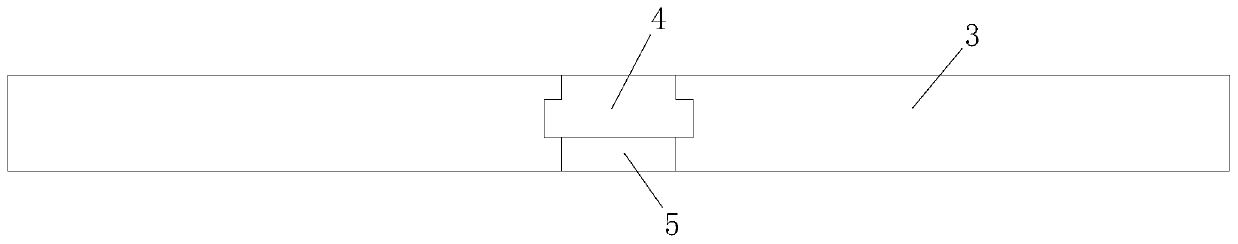

[0021] The bottom of the cell body 1 is provided with a sample slot 2, and the sample slot 2 is clamped with a sample stage 3 connected to the external circuit. The top surface of the sample stage 3 is provided with a slot 4 for fixing the attenuated total reflection crystal, and the slot bottom of the slot 4 There is a through hole 5 capable of passing infrared light, the clamping slot 4 is a stepped groove, and the stage diameter of the clamping slot 4 close to the through hole 5 is larger than the stage diameter of the stage away from the through hole 5. A lower gasket 16 that can transmit infrared light is connected to the bottom of the pool body 1.

[0022] The side wall of the pool body 1 is provided with a first window 6, a second window 7, and a third window 8. The first window 6 and the second window 7 are respectively ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com