Battery pole piece scratch detection system and detection method

A battery pole piece and detection system technology, applied in the direction of measuring devices, optical testing flaws/defects, image data processing, etc., can solve the problems of automatic detection systems such as false detection, low accuracy, and hysteresis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0074] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention clearer, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention. Obviously, the described embodiments It is a part of embodiments of the present invention, but not all embodiments.

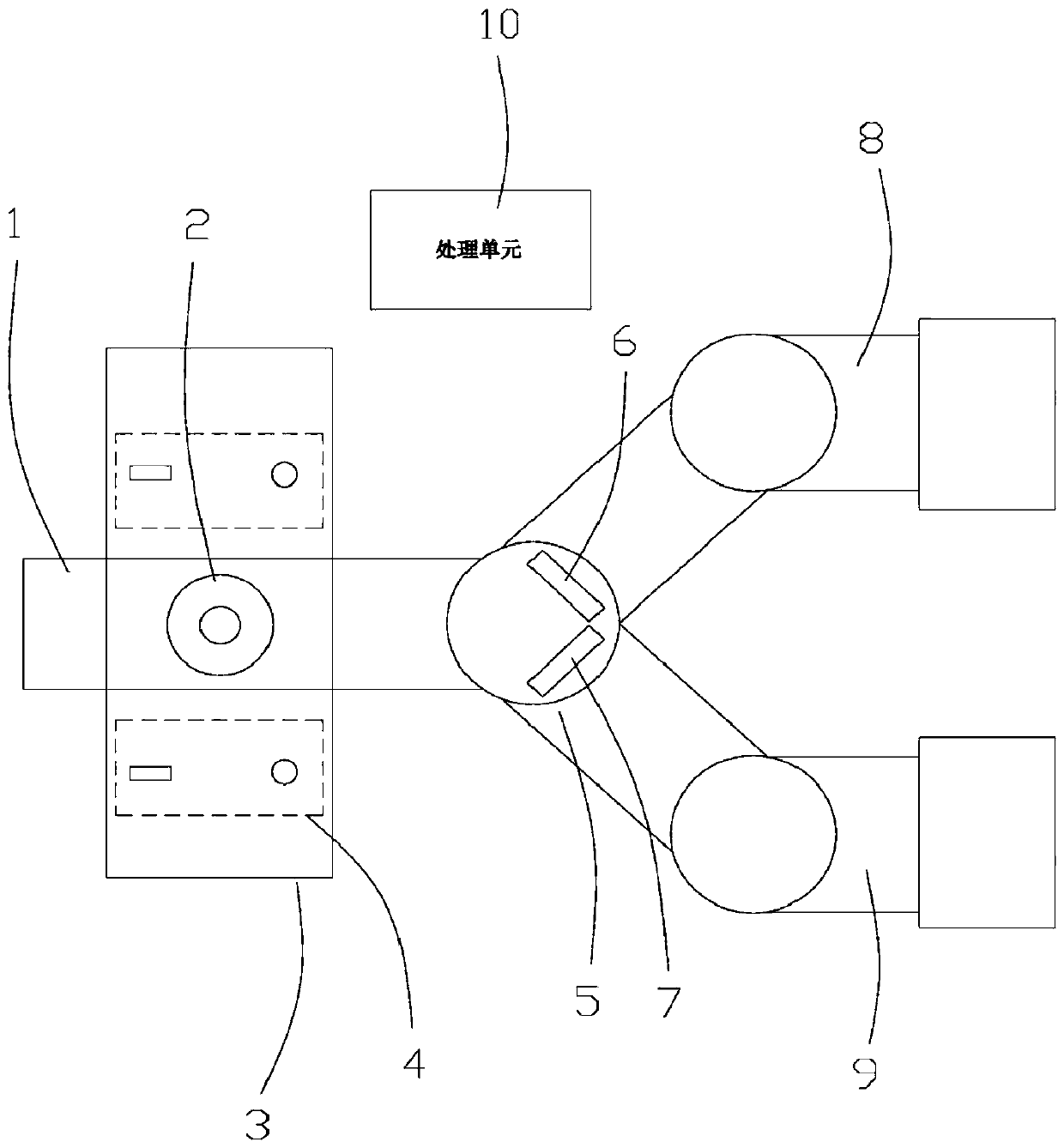

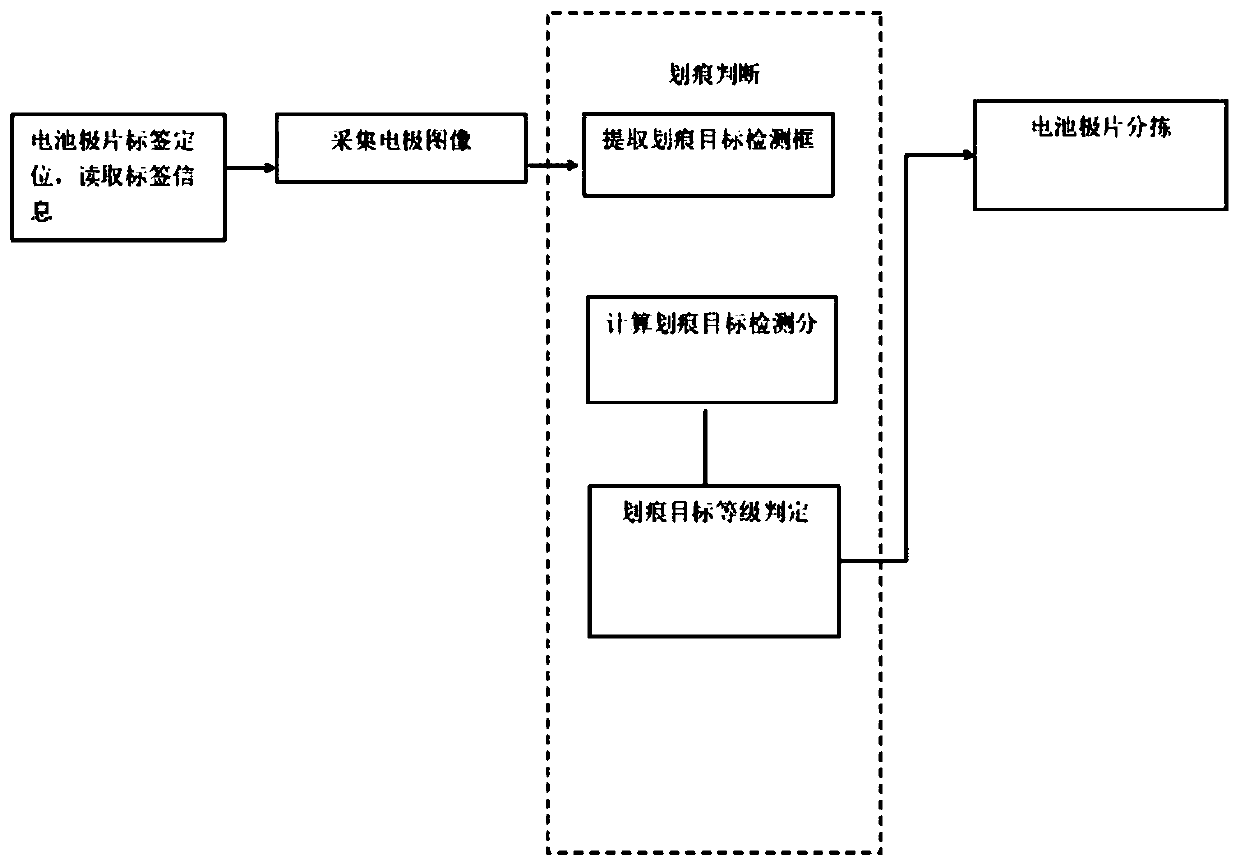

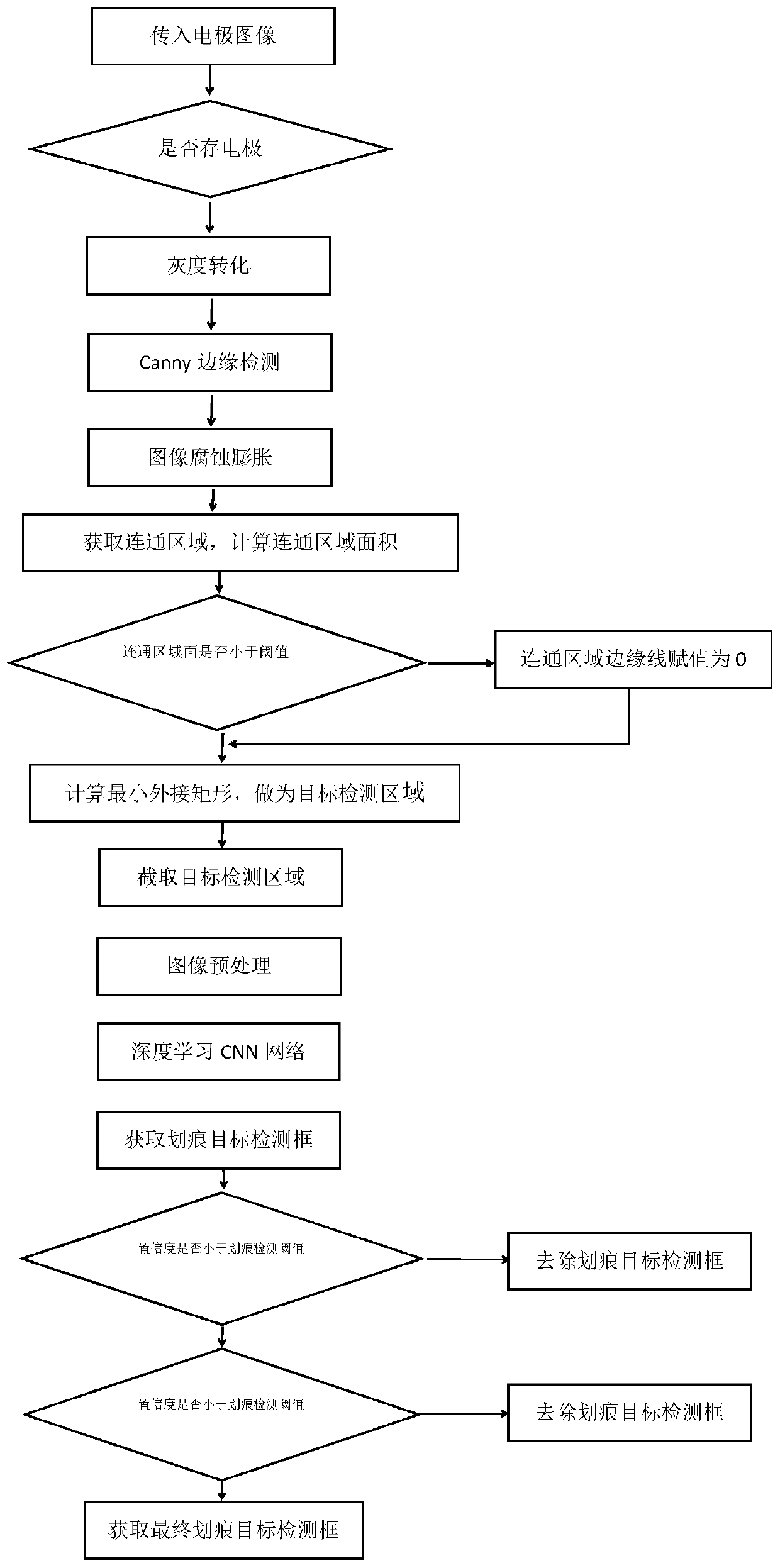

[0075] Such as figure 1 As shown, the battery pole piece scratch detection system described in this embodiment includes a holding platform 2 for loading battery pole pieces, a label is provided on the battery pole piece, and a rotating belt 1 for transporting the holding platform is placed on the rotating belt. A supporting box 3 is provided, a sorting module 5 is arranged on the rotating belt behind the supporting box, and a picture collecting module 4 for collecting label pictures and battery pole piece pictures is arranged in the supporting box, ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap