Array type multistage semiconductor refrigeration method for large-target-surface detector

A detector array and semiconductor technology, applied in the direction of semiconductor devices, electric solid devices, radiation control devices, etc., can solve the problems of large volume, affecting the cooling effect of detectors, complex structure, etc., to improve efficiency, suppress dark current noise, Effect of reducing thermal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

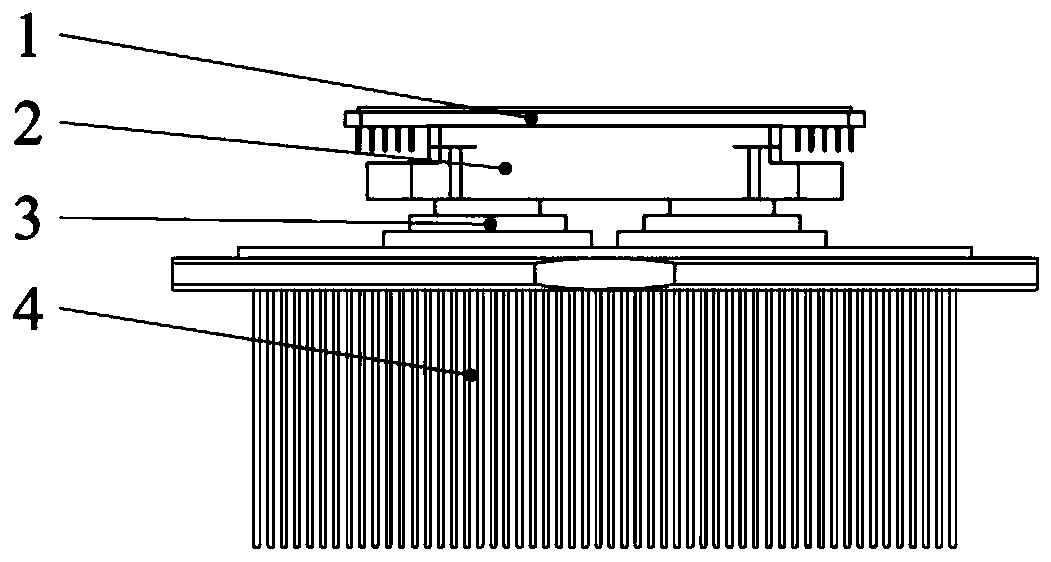

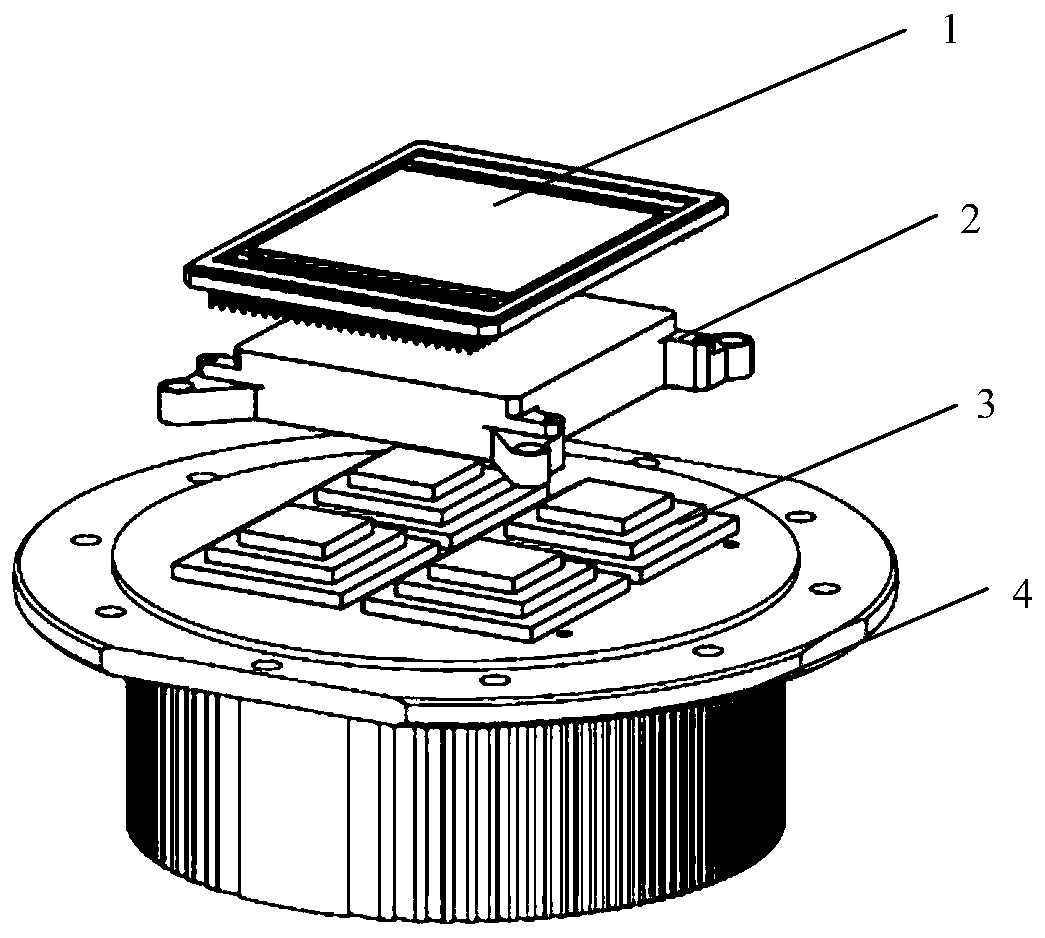

[0013] Specific implementation mode 1. Combination figure 1 and figure 2 Describe this embodiment, a large target surface (pixel 6K × 6K) detector array multi-stage semiconductor refrigeration device, including a large target surface (pixel 6K × 6K) detector 1, cold plate 2, array multistage semiconductor refrigerator 3 and heat sink 4, using a 2×2 array of multi-stage semiconductor coolers to cool the large target surface (pixel 6K×6K) detectors, using series, parallel or series-parallel combinations between the semiconductor coolers, the array Low-temperature solder is used for welding between the hot end and the heat sink of the semiconductor refrigerator, and between the cold end of the array semiconductor and the cold plate. The low-temperature solder refers to the solder with a melting point of <200°C. The molten low-temperature solder can form a metallographic structure at the weld after cooling , so that there is no gap between the semiconductor cooler and the cold p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com