Pole plate group continuous slot entering device for lead-acid storage battery

A lead-acid battery and battery technology, which is applied in the construction, transportation and packaging of lead-acid batteries and lead-acid batteries, can solve the problems of inability to continuously enter the tank and low work efficiency, and achieve good tank entry effect and tank entry. Accurate method and the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

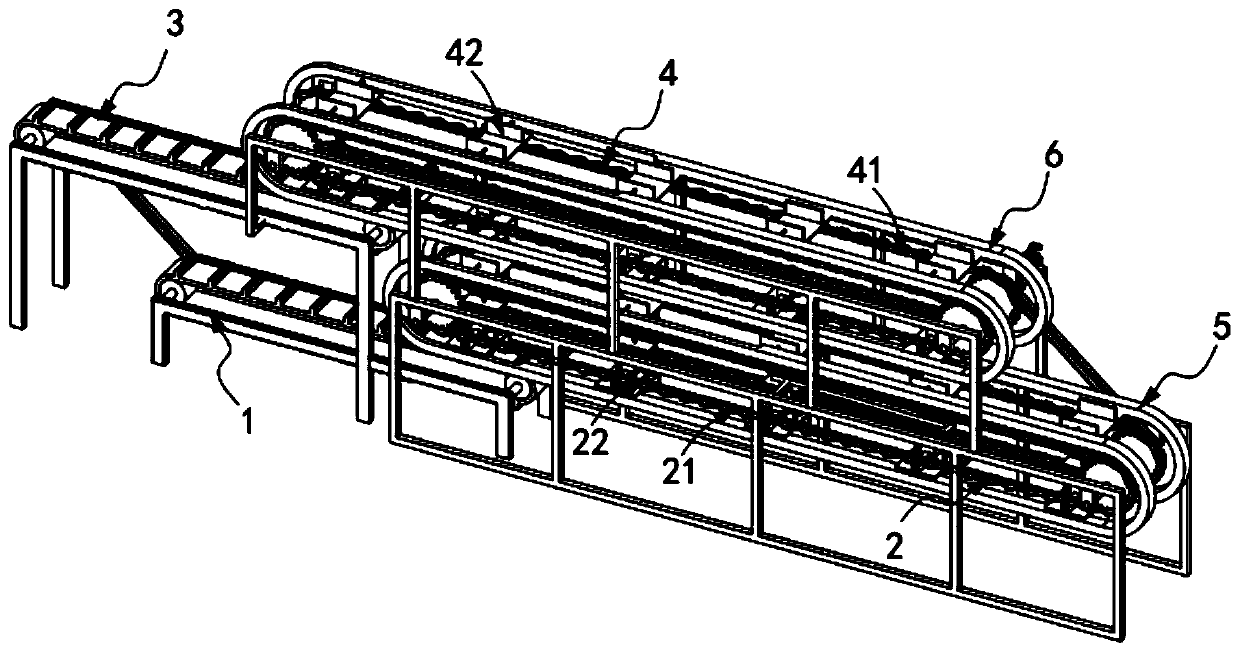

[0048] Such as figure 1 As shown, a lead-acid storage battery uses an electrode group continuous slotting device, including:

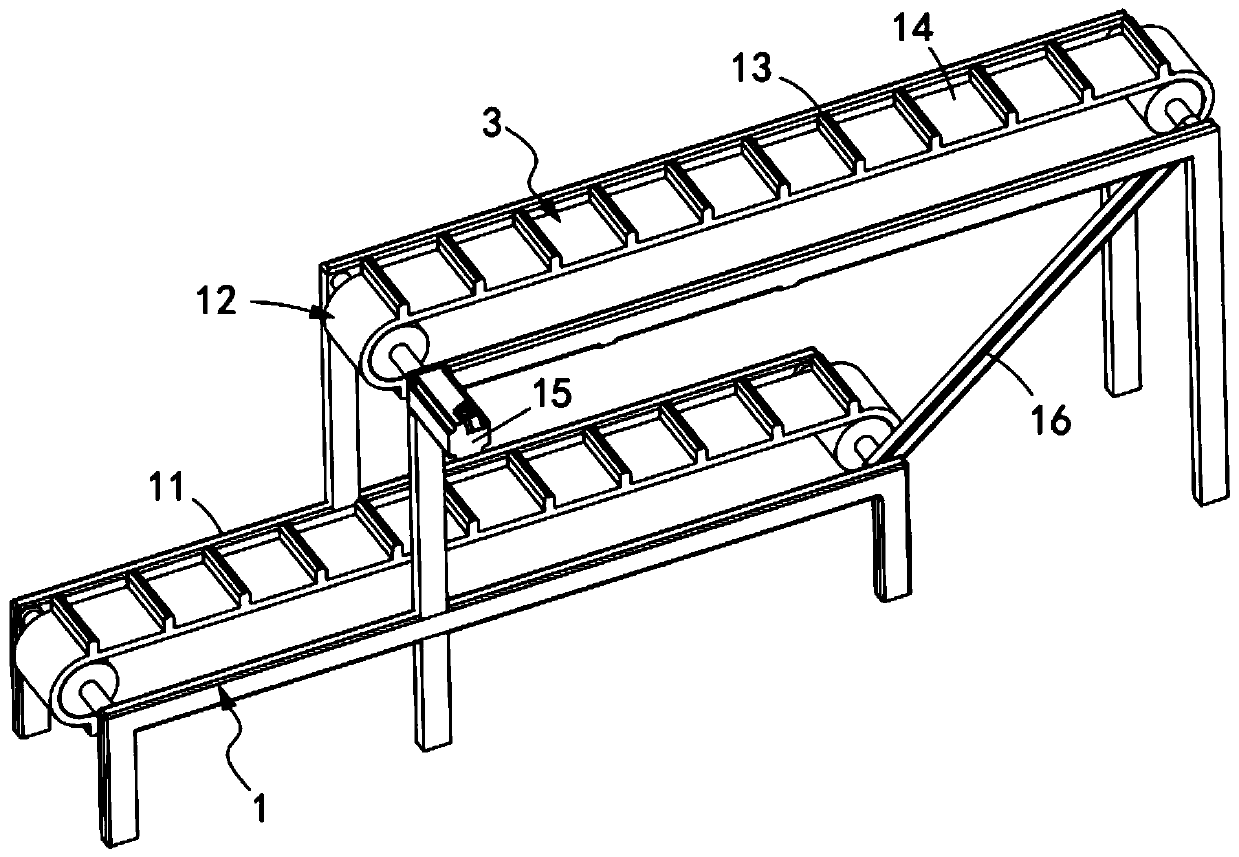

[0049] The pole group transmission mechanism 1, the pole group transmission mechanism 1 is used to sequentially transport several groups of pole groups 10 backward;

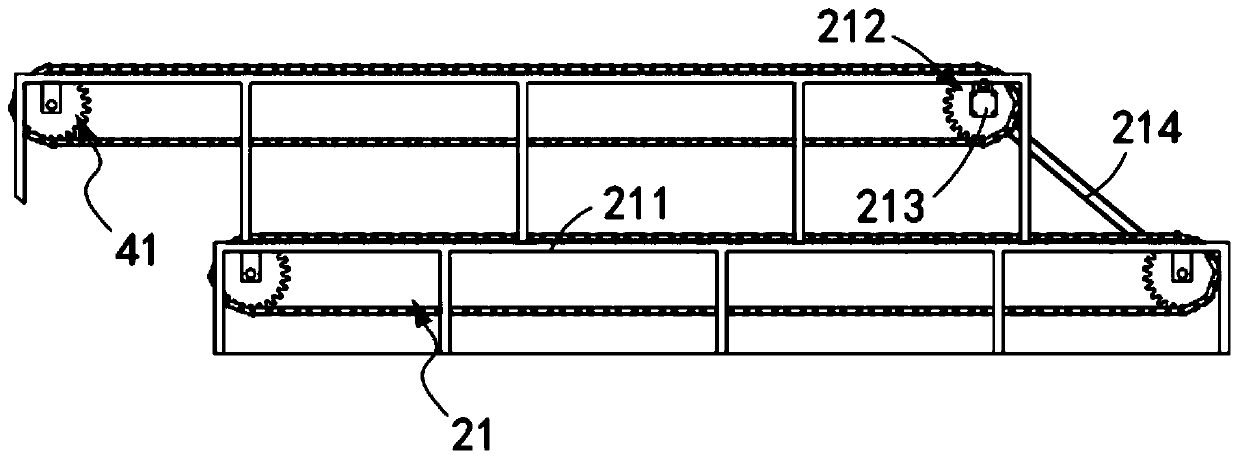

[0050] The pole group clamping mechanism 2, the pole group clamping mechanism 2 is located above the pole group transmission mechanism 1, and it includes a first transmission assembly 21 and a number of equidistant along the transmission direction of the first transmission assembly 21. A first tightening component 22 assembled and installed on the first conveying component 21;

[0051] A shell transmission mechanism 3, which is arranged above the pole group clamping mechanism 2, and is used to sequentially transport several groups of battery shells backwards; and

[0052] The shell clamping mechanism 4, the shell clamping mechanism 4 is located above the shell transmission mechanism 3, ...

Embodiment 2

[0074] As shown in Figure 16, Figure 14 As shown in FIG. 15 , the parts that are the same as or corresponding to those in the first embodiment are marked with the corresponding reference numerals of the first embodiment. For the sake of brevity, only the differences from the first embodiment are described below. The difference between this embodiment two and embodiment one is:

[0075] Further, as shown in Figure 16, Figure 14 As shown in FIG. 15, the third guide assembly 7 includes a sliding seat 71 vertically slidably arranged on the base 221 of the first tightening assembly 22, a connecting shaft 72 fixedly connected with the sliding seat 71, and The connecting shaft 72 is fixedly connected to the mounting plate 73, the control rod 74 installed on the mounting plate 73, and the guide track c75. The mounting plate 73 is fixedly connected to the outer wall of the base 221 through two sets of telescopic units b76. The telescopic unit b76 includes a telescopic rod b77 and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com