Agricultural plantation greenhouse

A greenhouse and agricultural technology, applied in the field of agricultural planting greenhouses, can solve the problems of affecting the growth of seedlings, single greenhouse structure, poor use effect, etc., and achieve the effect of high greenhouse space utilization, large space for seedling cultivation, and increased use functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

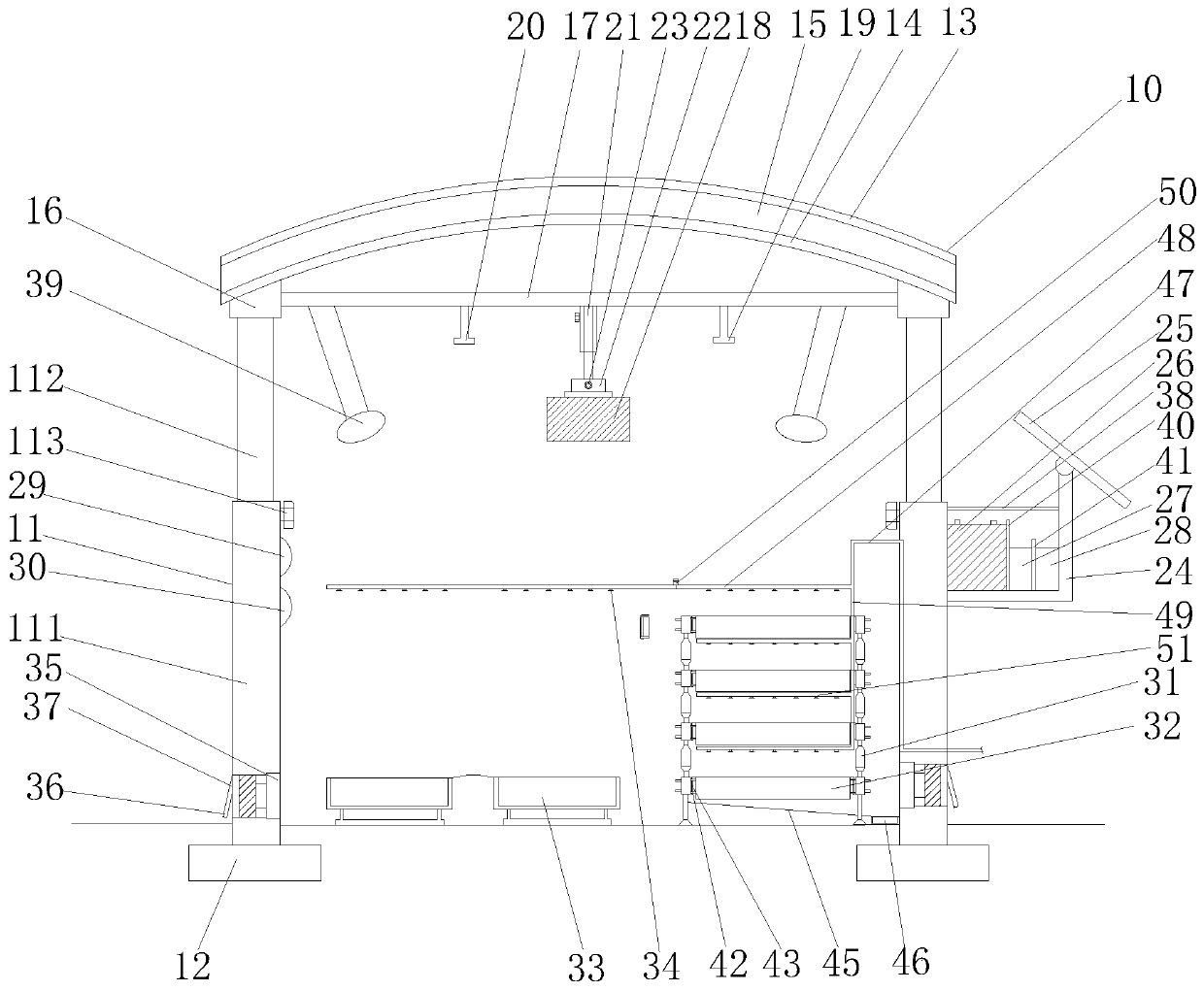

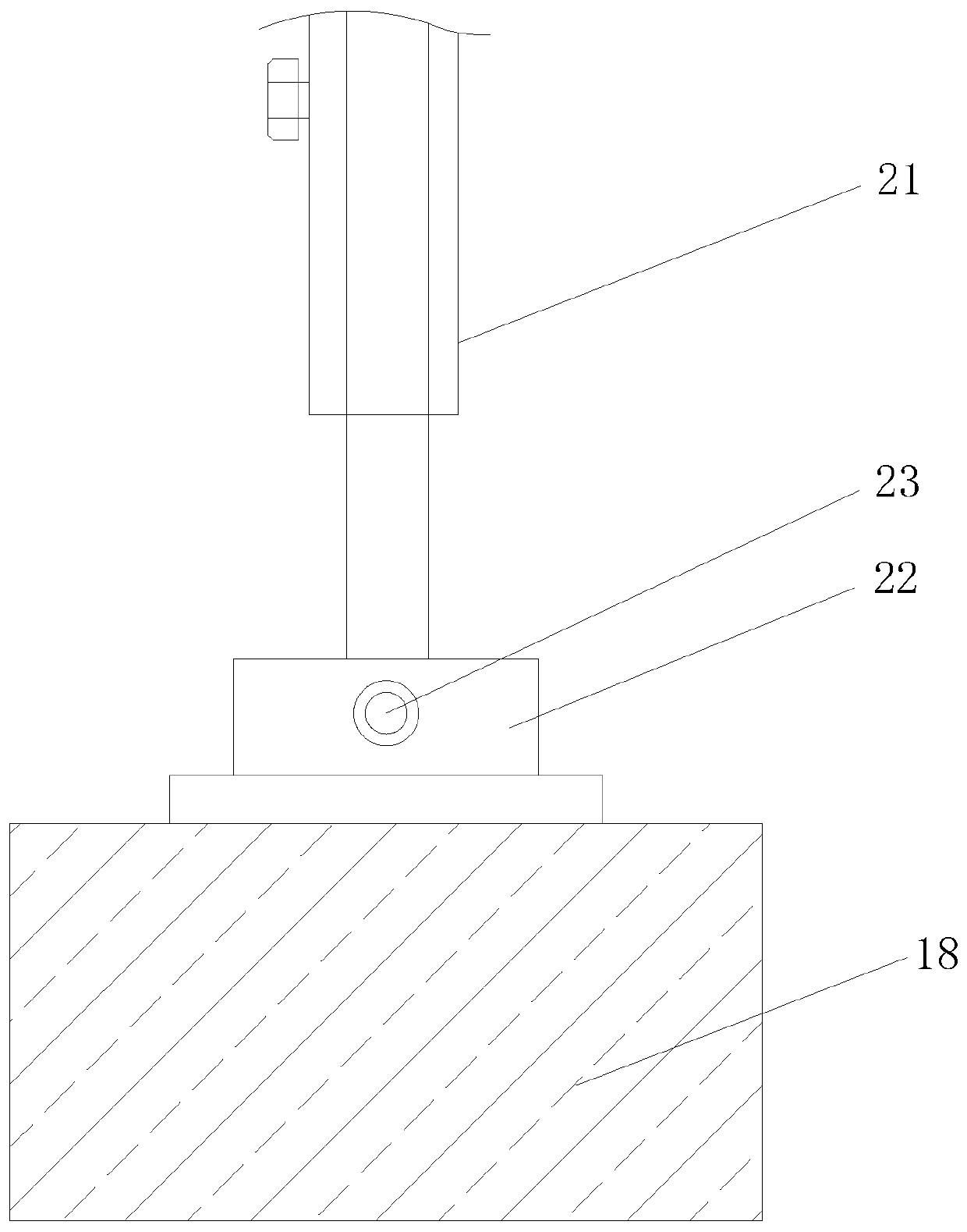

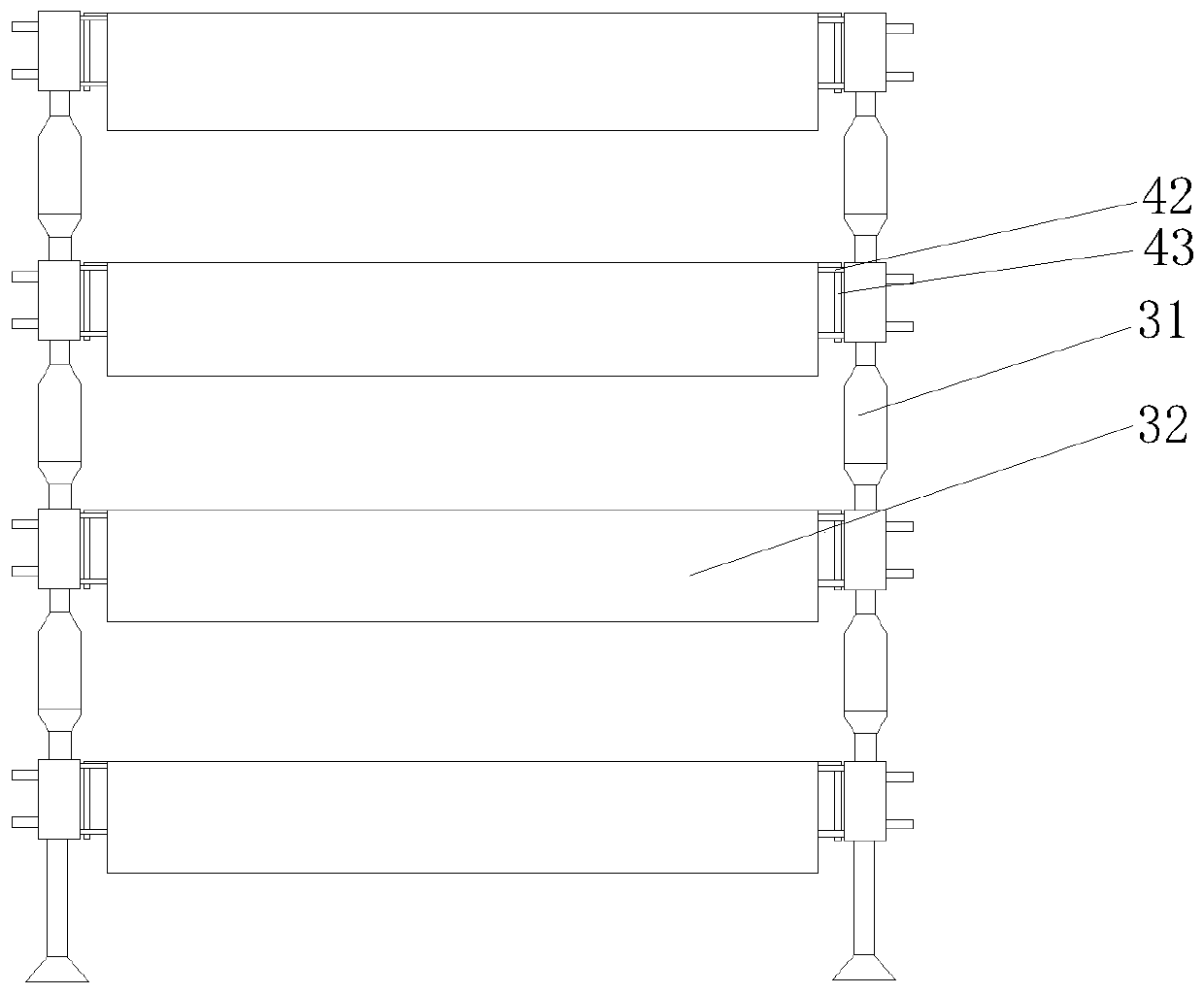

[0034] see Figure 1-6 , the present invention provides a technical solution: an agricultural planting greenhouse, including a roof board 10, a telescopic column 11 and a pre-embedded base 12, the roof board 10 is installed on the top of the telescopic column 11, and the telescopic column 11 is fixed on the embedded base 12 Above, the roof board 10 is respectively provided with a plastic film I13 and a plastic film II14 on the outside and inside, an air separation layer 15 is formed between the plastic film I13 and the plastic film II14, and a connecting seat 16 is provided between the roof board 10 and the telescopic column 11 , a beam 17 is arranged between the connecting seats 16, a display screen 18, a temperature sensor 19 and a humidity sensor 20 are installed at the bottom of the beam 17, and an adjustment rod 21 and a connecting rod 22 are arranged on the upper end of the display screen 18, and on the connecting rod 22 Camera 23 is installed, and temperature sensor 19,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com