Orthogonal glued bamboo material for building structure and preparation method thereof

A technology for building structures and bamboo materials, which can be applied to other plywood/plywood appliances, manufacturing tools, mechanical equipment, etc., can solve the problems of low mechanical properties of bamboo materials, and achieve uniform stress on the whole bamboo strips, solve stress concentration, and improve uniformity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention is described in further detail below in conjunction with accompanying drawing:

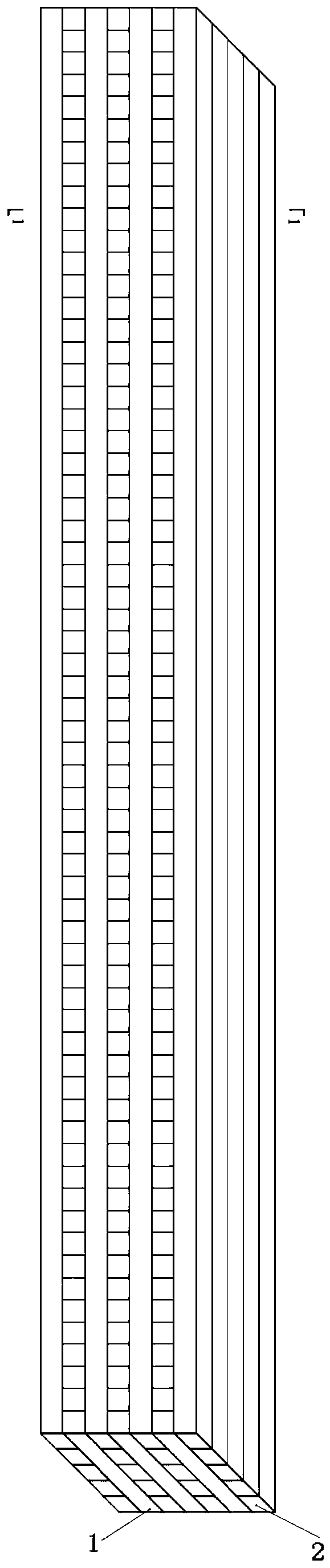

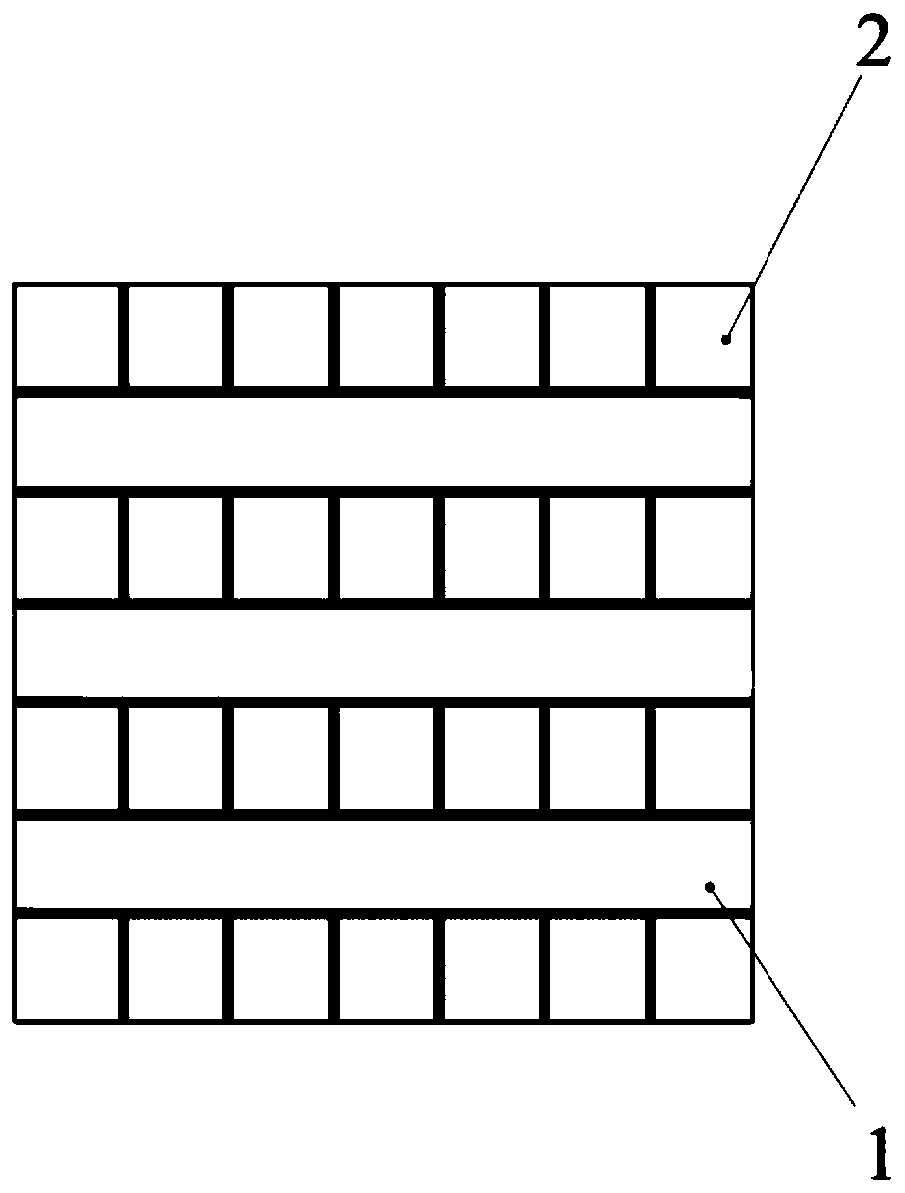

[0040] Such as figure 1 As shown, the bamboo material includes a plurality of bamboo strips.

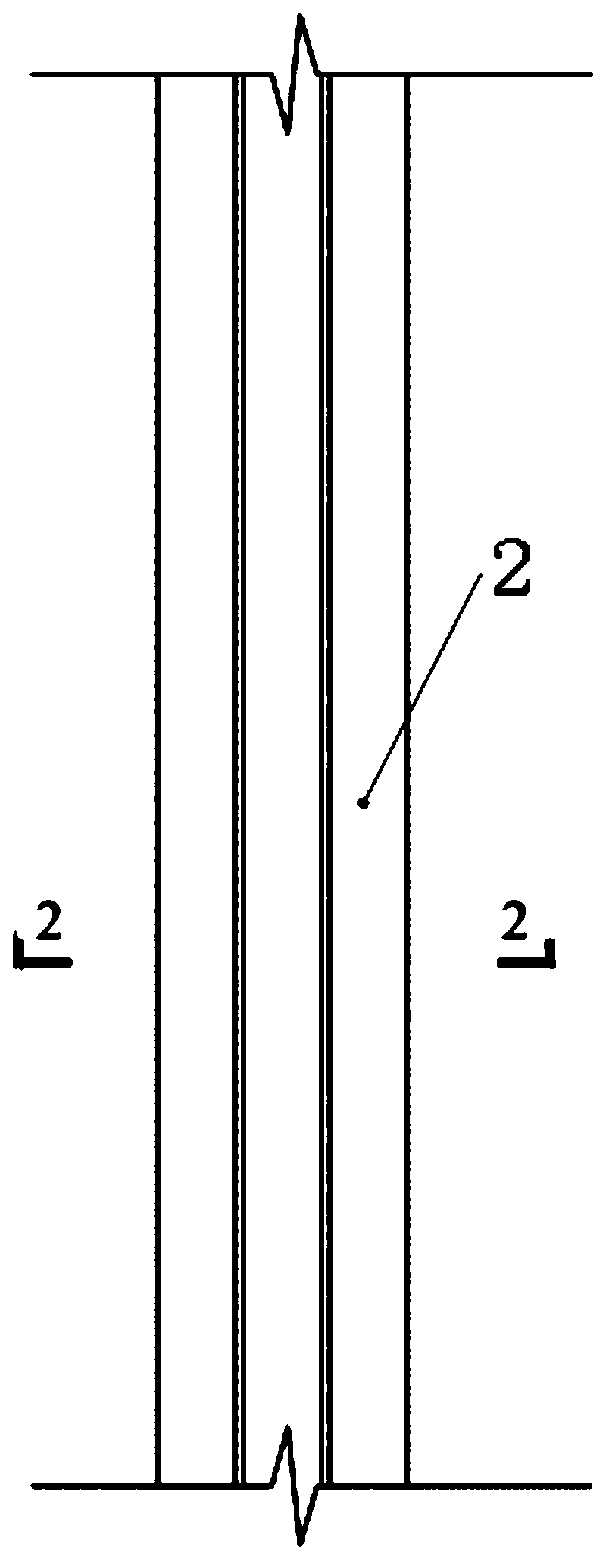

[0041] Bamboo strips include short bamboo strips 1 and long bamboo strips 2, and the cross-section sizes of short bamboo strips 1 and long bamboo strips 2 are the same; multiple short bamboo strips 1 are arranged side by side, and are arranged in parallel as longitudinal boards; multiple long bamboo strips 2 are arranged side by side, Side by side as horizontal boards; vertical boards and horizontal boards have the same size, the width of the vertical boards is equal to the length of the long bamboo strip 2, the width of the horizontal boards is equal to the length of the short bamboo strips 1, and the vertical boards and horizontal boards are staggered Bamboo is formed by stacking, the axes of the short bamboo strip 1 and the long bamboo strip 2 are perpendicular, and the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

| Brookfield viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com