Flexible knitting soft interlayer used for pulse engine and manufacturing method

An engine and interlayer technology, applied in the direction of machines/engines, rocket engine devices, mechanical equipment, etc., can solve problems such as stiffness and bearing capacity requirements, and achieve the effect of meeting the pressure resistance and solving the stiffness and bearing capacity requirements of different positions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] The length of the horizontal section of the prefabricated interlayer of the pulse engine soft interlayer in this embodiment is 30mm, the length of the prefabricated interlayer cone section is 150mm, and the length of the prefabricated interlayer column section is 460mm; the maximum diameter of the prefabricated interlayer cone section is 324mm, and the prefabricated The minimum diameter of the cone section of the body compartment is 103mm, and the diameter of the column section of the prefabricated body compartment is 103mm; the lateral projection length of the cone section of the prefabricated body compartment is 93.1mm, and the connection angle is 47.7°; the fiber is selected from aramid 1414, and the rubber matrix is selected from EPDM rubber. The matrix content is 60%.

[0044] Concrete preparation steps are:

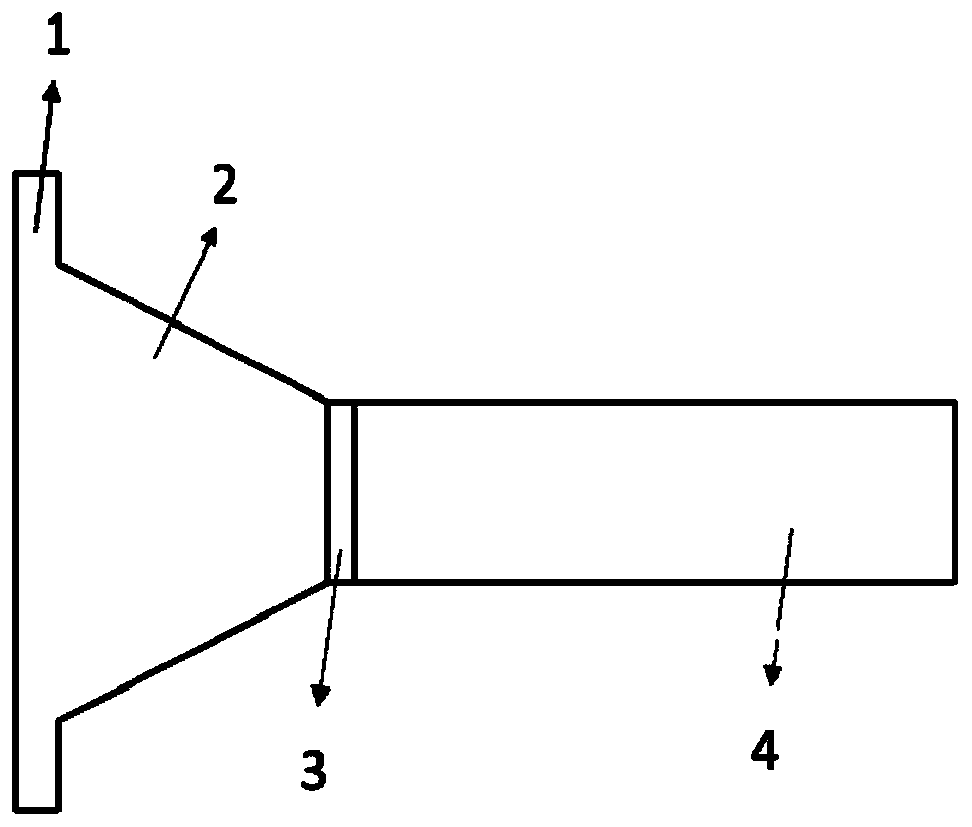

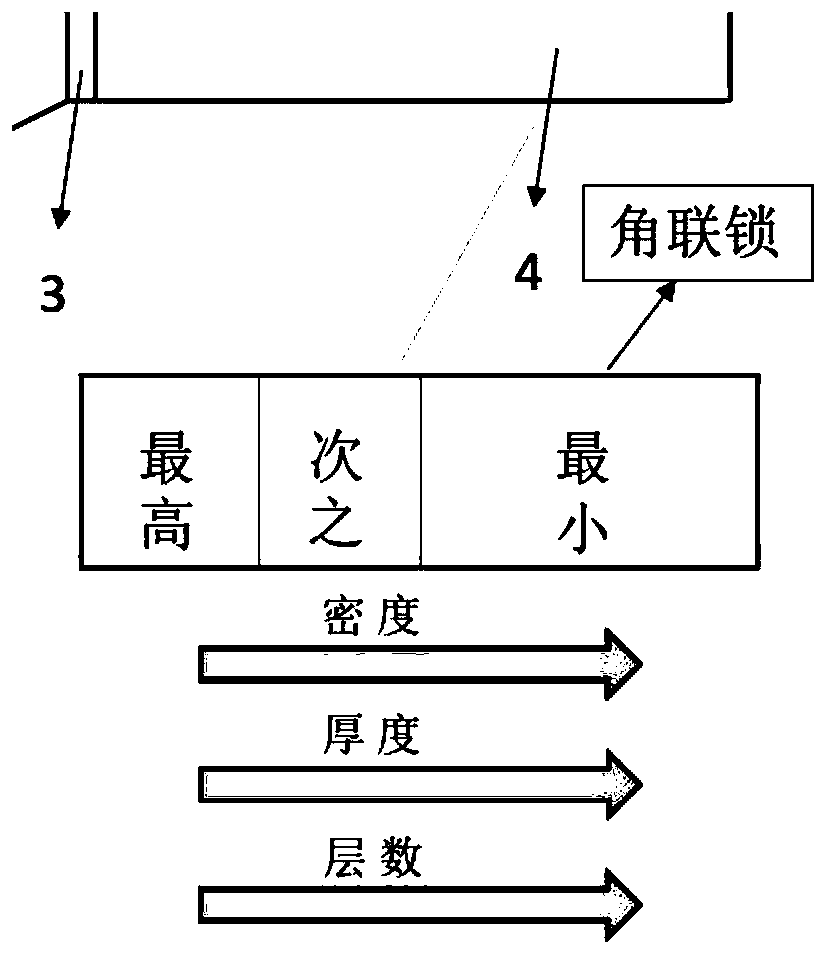

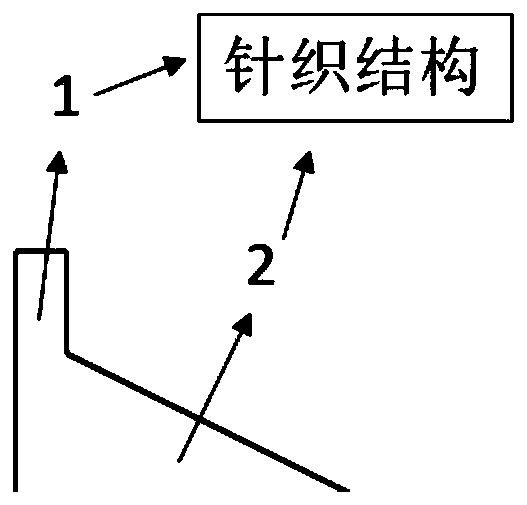

[0045] (1) if figure 1 Shown is a schematic diagram of the structure of the soft compartment. from figure 1 It can be seen that the soft interlayer of t...

Embodiment 2

[0053] The length of the horizontal section of the prefabricated interlayer of the pulse engine soft interlayer in this embodiment is 50mm, the length of the prefabricated interlayer cone section is 300mm, and the length of the prefabricated interlayer column section is 800mm; the maximum diameter of the prefabricated interlayer cone section is 600mm, and the prefabricated The minimum diameter of the cone section of the body compartment is 220mm, and the diameter of the column section of the prefabricated body compartment is 220mm; the lateral projection length of the cone section of the prefabricated body compartment is 180mm, and the connection angle is 47.7°; the fiber selection is aramid fiber 1414, and the rubber matrix is EPDM rubber. The content is 60%.

[0054] (1) A composite material soft interlayer for solid rocket multi-pulse motors, the soft interlayer of the pulse engine mainly includes three parts: the interlayer horizontal section, the interlayer cone section,...

Embodiment 3

[0062] The length of the horizontal section of the prefabricated interlayer of the pulse engine soft interlayer in this embodiment is 50mm, the length of the prefabricated interlayer cone section is 300mm, and the length of the prefabricated interlayer column section is 800mm; the maximum diameter of the prefabricated interlayer cone section is 600mm, and the prefabricated The minimum diameter of the cone section of the body compartment is 220mm, and the diameter of the column section of the prefabricated body compartment is 220mm; the lateral projection length of the cone section of the prefabricated body compartment is 180mm, and the connection angle is 47.7°; the fiber is selected from aramid 1313 fiber, and the rubber matrix is selected from polyurethane rubber. The content of the matrix is 60%.

[0063] The preparation method is the same as in Example 2. The pressure of the obtained flexible braided soft interlayer for pulse engines is 38MPa, the pressure time is 44s, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal decomposition temperature | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com