Material lifting device for building engineering construction and using method thereof

A technology of construction engineering and materials, applied in the direction of building structure, processing of building materials, elevators in buildings, etc., can solve the problems that affect the service life of the transport box, easily endanger the health of workers, and the device is easy to be contaminated with dust, etc., to achieve The structural design is novel and compact, which can ensure the health of the body and improve the effect of resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

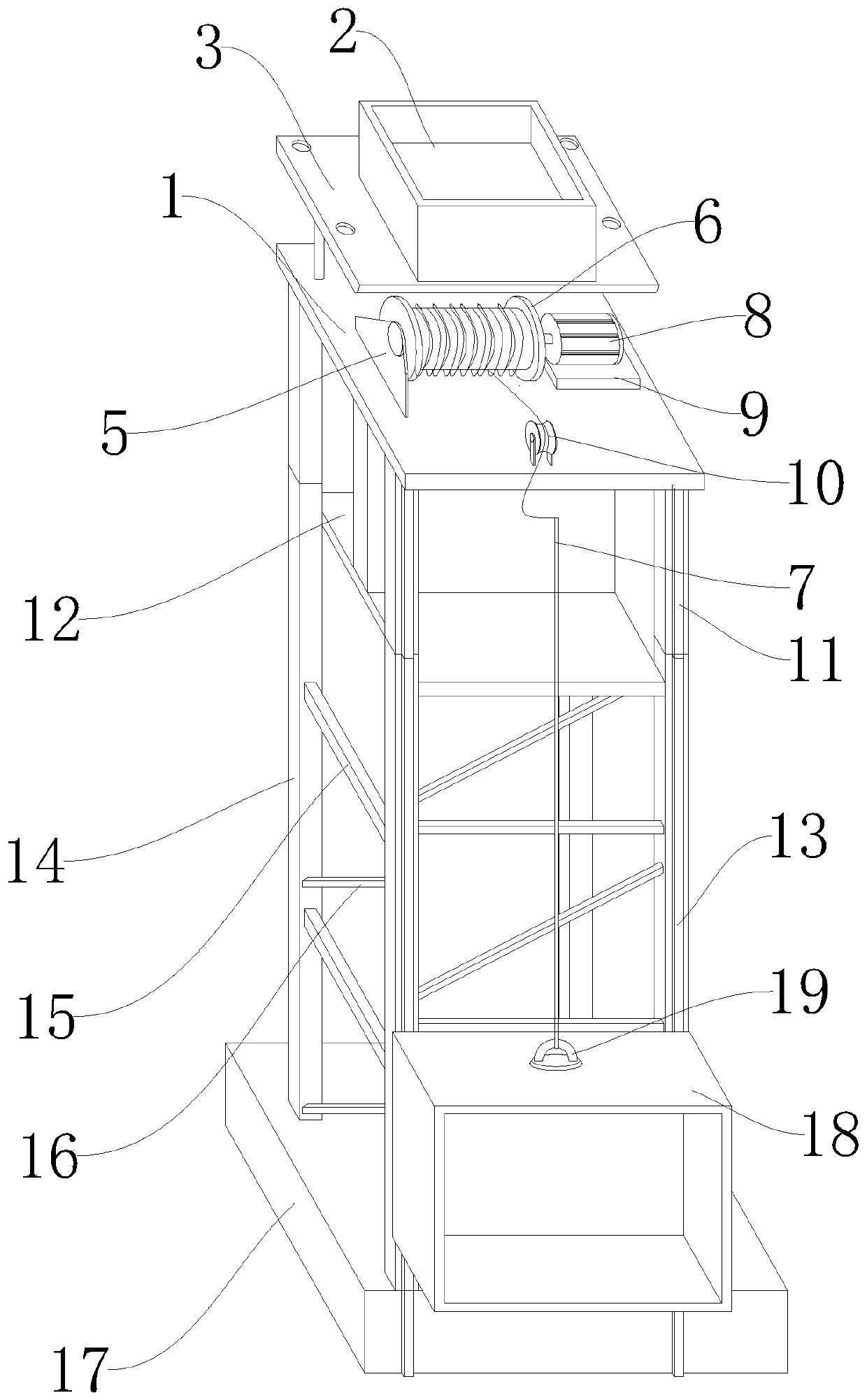

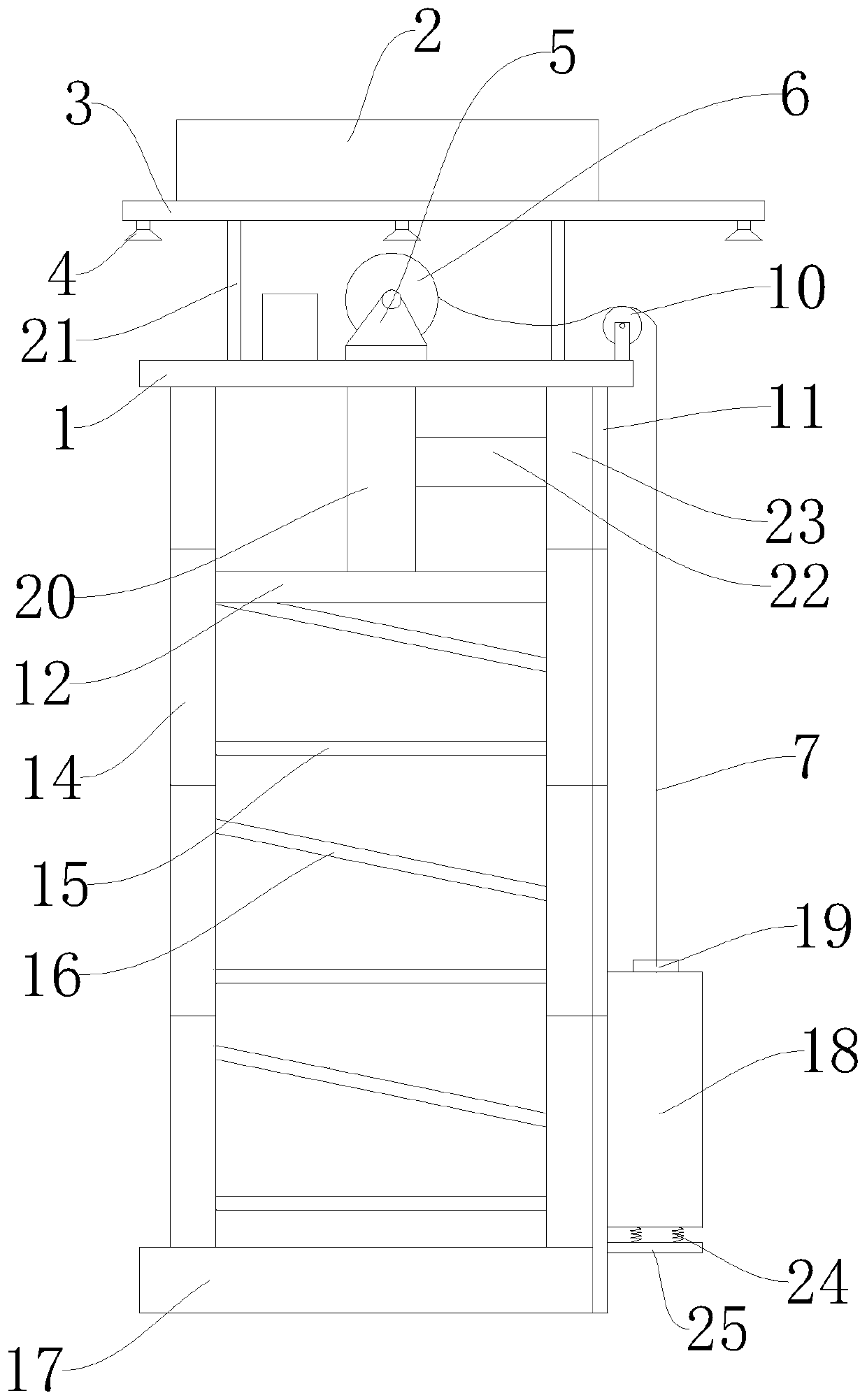

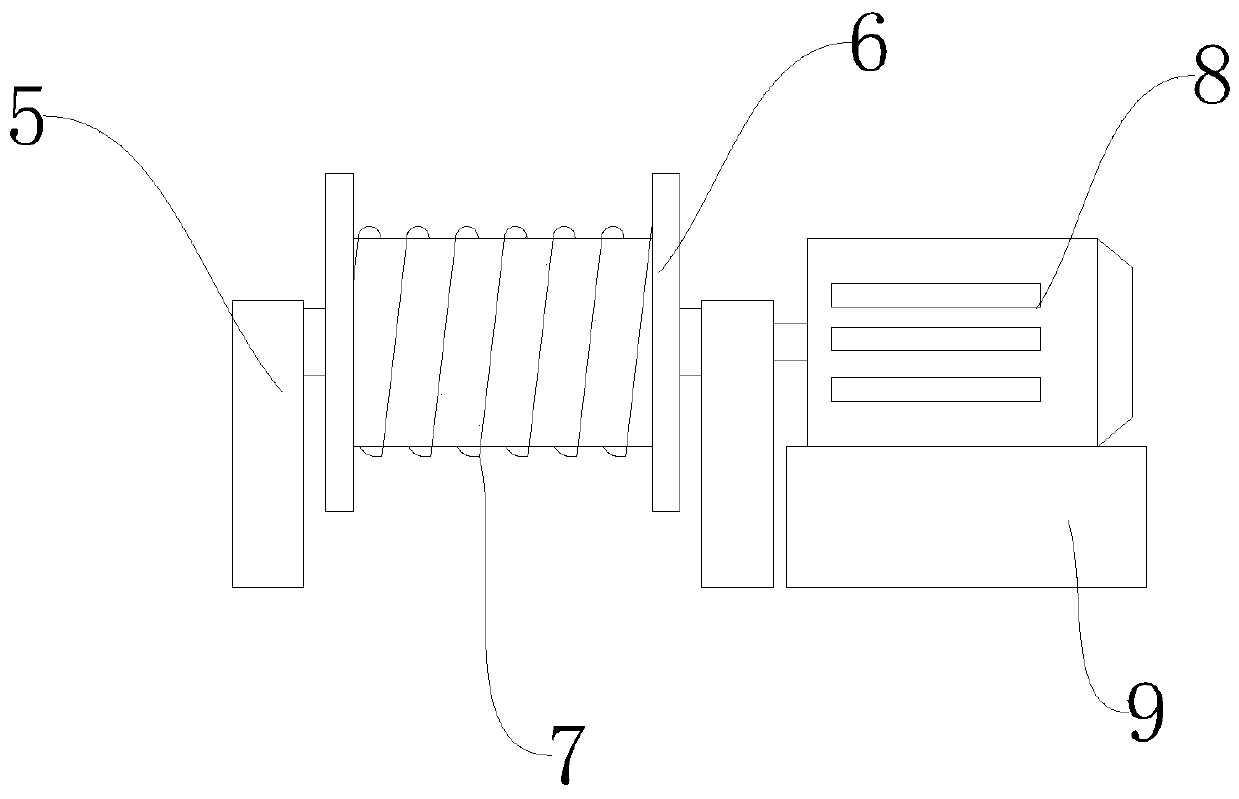

[0036]The present invention is a material hoisting device for construction engineering, comprising a rectangular base 17 and a transport box 18, a support rod 14 is respectively arranged at the four corners of the base 17, and the upper and top parts of the four support rods 14 are The support platform 12 and the top plate 1 are respectively arranged through bolt connection, the two support rods 14 on the same side of the four support rods 14 are correspondingly provided with the second slide rail 13, and the upper part of the second slide rail 13 is connected with the first Slide rail 11; Described transport case 18 is arranged on the second slide rail 13; Described top plate 1 is provided with traction device, and this traction device is connected with described transport case 18; The middle part of described support table 12 and top plate 1 A support plate 20 is provided, one side of the support plate 20 is connected with an electric push rod 22 through bolts, one side of th...

Embodiment 2

[0045] The method of using a material lifting device for construction engineering described in Example 1 is characterized in that: when in use, the device is connected to an external power supply, and the terminal control device is used to run the material that needs to be lifted into the In the transport box 18, the motor 8 is controlled by the terminal to work, and the motor 8 drives the reel 6 to rotate, so that the steel rope 7 is retracted, and the steel rope 7 is carried out by the fixed pulley 10. guide and drive the transport box 18 to move upward along the second slide rail 13, and when the transport box 18 moves to the position of the first slide rail 11, the terminal controls the electric push rod 22 to push the The sliding plate 23 moves, and then pushes the first slide rail 11 and the transport box 18 to move laterally through the sliding plate 23, so as to facilitate unloading after reaching a predetermined position, greatly improving work efficiency and increasin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com