Fiber strand detection device for four-roller ring frame

A detection device and technology of spinning frame, applied in textiles and papermaking, etc., can solve problems such as inconvenience, inability to realize capacitive whisker detector, and no stable state of yarn whiskers in spinning section, and achieve the effect of setting optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

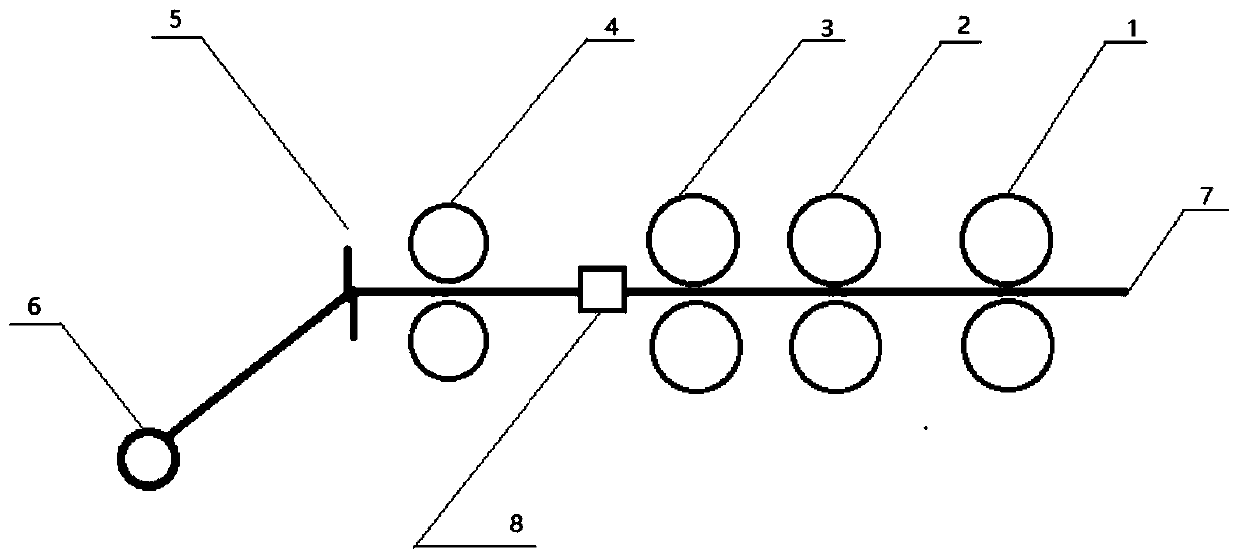

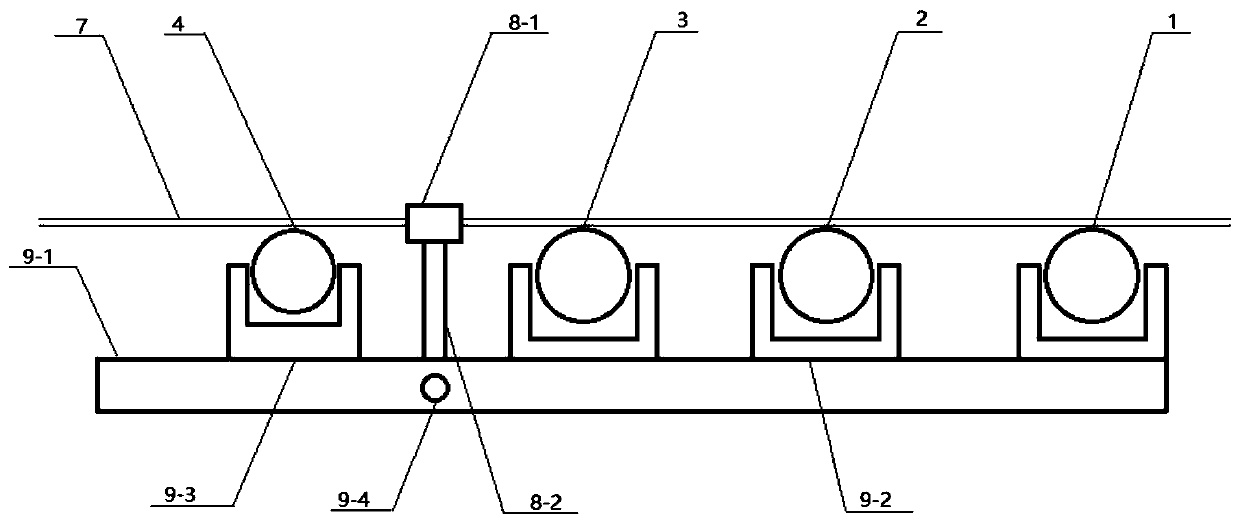

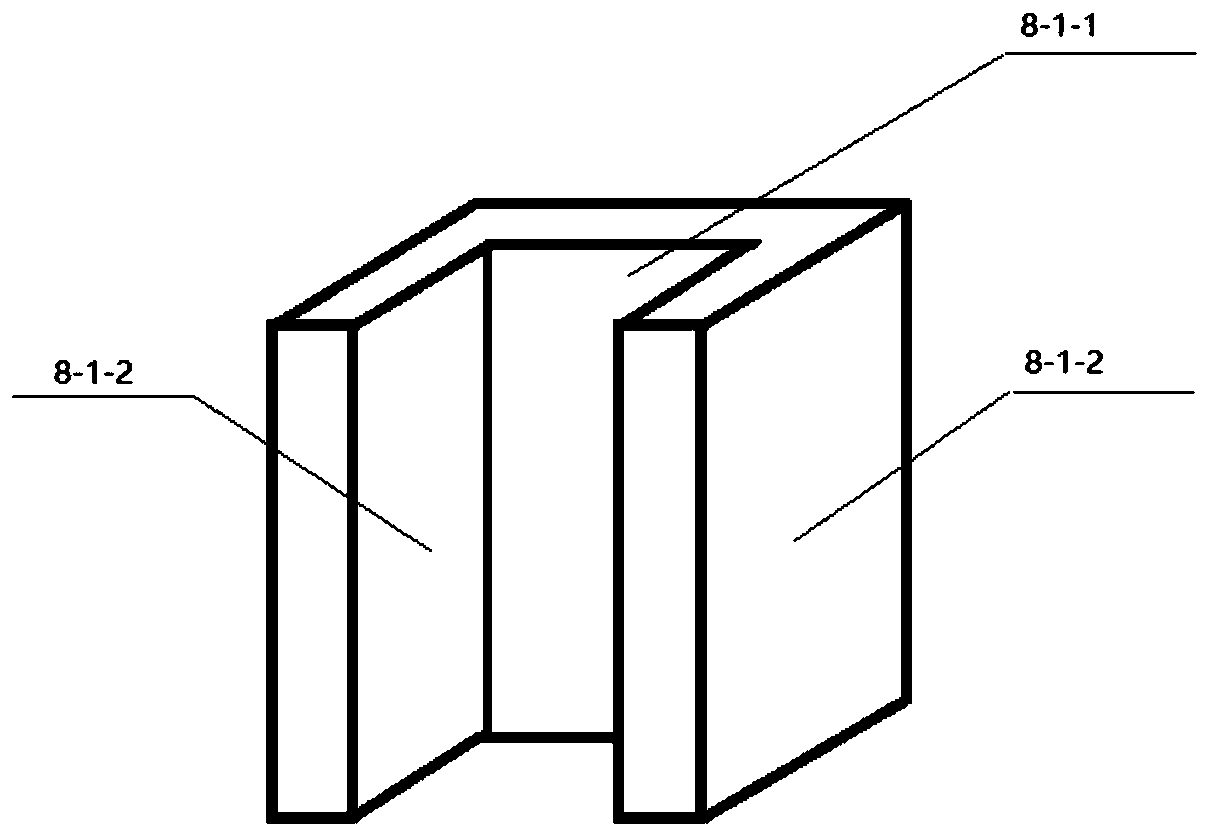

[0025] A sliver detection device for a four-roller ring spinning frame disclosed in this embodiment includes a drafting mechanism unit, a signal detection mechanism unit, and a signal acquisition unit. Among them, the drafting mechanism unit has a four-roller drafting mechanism, such as figure 1 As shown, the four-roller drafting mechanism includes a rear roller pair 1, a middle roller pair 2, a front roller pair 3, an output roller pair 4, and a roller support device, which are combined to form a four-roller controlled drafting mechanism, and the ring spinning frame The yarn guide hook 5 and the spindle 6 jointly constitute a four-roller ring spinning frame. The signal detection mechanism includes a capacitive sliver detection device 8, and the capacitive sliver detector 8 is arranged between the front roller pair 3 and the output roller pair 4, and the front roller pair 3 and the output roller pair 4 provide control for the passing yarn sliver 7, The yarn 7 is in a relative...

example 2

[0032] A sliver detection device for a four-roller ring spinning frame disclosed in this embodiment includes a drafting mechanism unit, a signal detection mechanism unit, and a signal acquisition unit. The drafting mechanism unit has a four-roller drafting mechanism, such as figure 1 As shown, the four-roller drafting mechanism includes a rear roller pair 1, a middle roller pair 2, a front roller pair 3, an output roller pair 4 and a roller supporting device, which are combined to form a four-roller controlled drafting mechanism, and the ring spinning frame The yarn guide hook 5 and the spindle 6 jointly constitute a four-roller ring spinning frame. The signal detection mechanism includes a capacitive sliver detection device 8, and the capacitive sliver detector 8 is arranged between the front roller pair 3 and the output roller pair 4, and the front roller pair 3 and the output roller pair 4 provide control for the passing yarn 7 , the yarn 7 is in a relatively stable state ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com