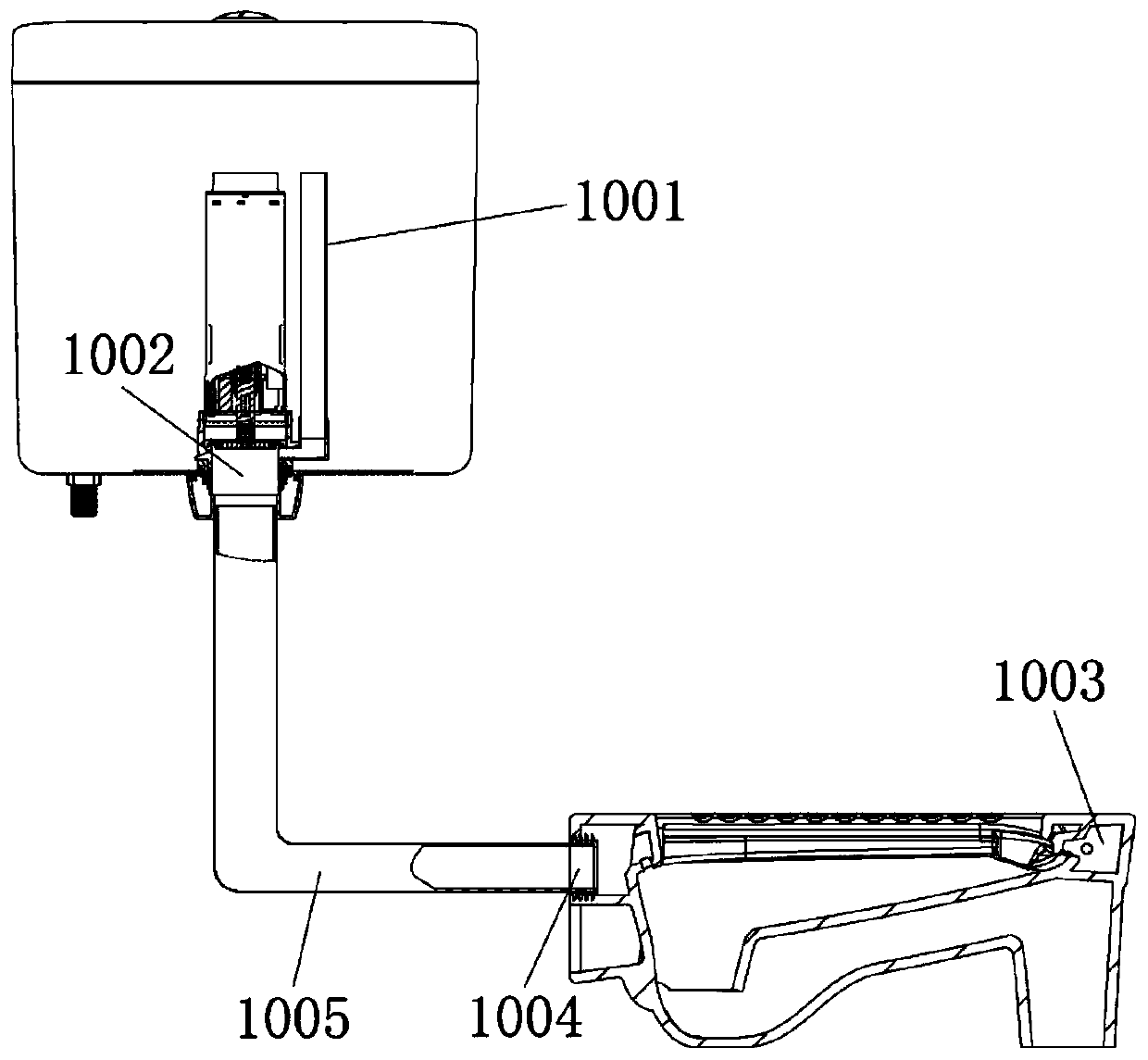

Squatting pan and squatting pan flushing system

A squatting toilet and flushing technology, applied in the field of bathroom, can solve the problems of reduced drainage speed and large drainage noise, and achieve the effects of saving stroke, reducing noise and improving flushing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

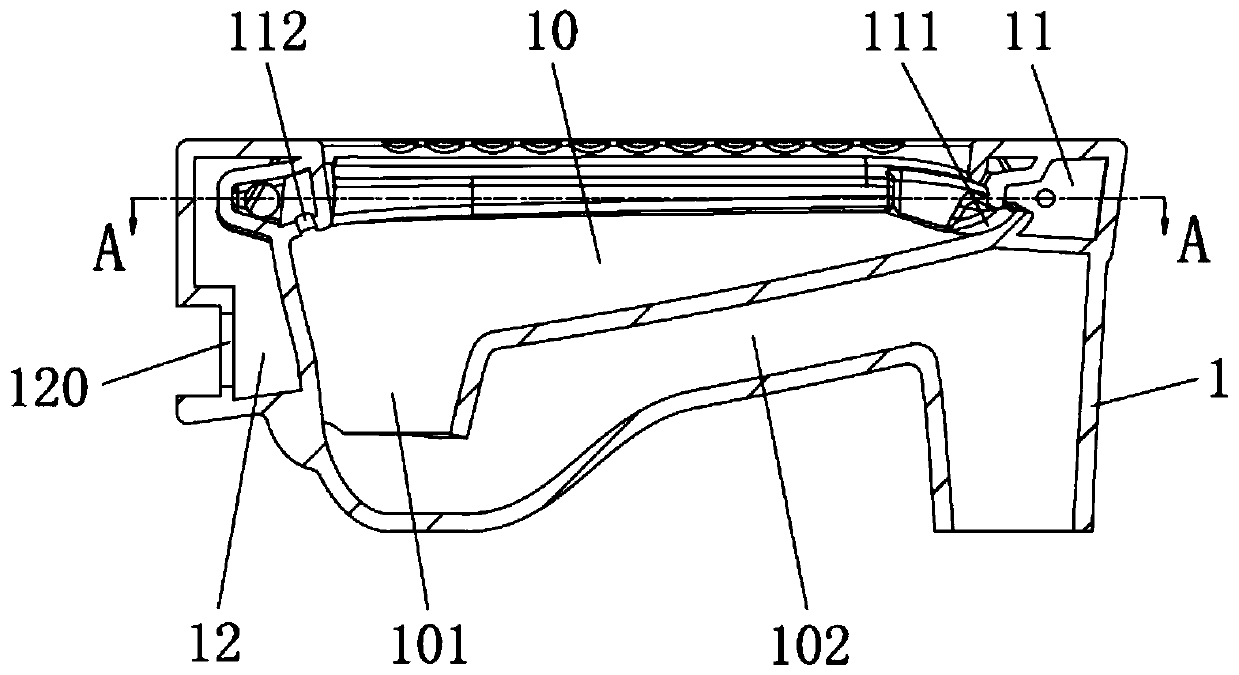

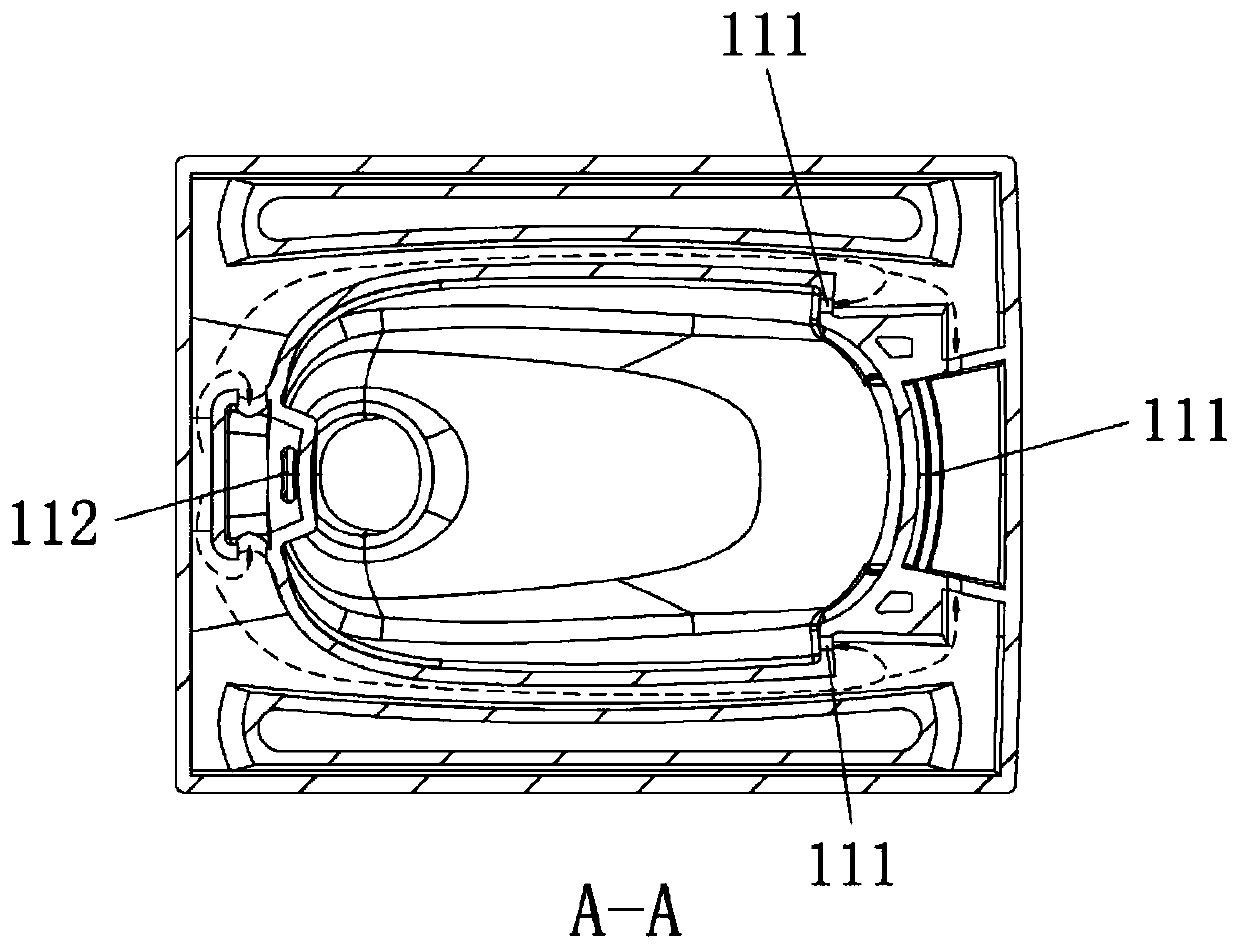

[0029] Such as figure 2 , image 3 As shown, a squatting pan includes a squatting pan ceramic body 1, a urinal 10 is provided on the top of the squatting pan ceramic body 1, a sinking bay 101 is provided at the bottom of the squatting pan 10, and a sewage siphon 102 is connected to the sinking bay 101. The top of the urinal 10 is surrounded by an annular flushing pipe 11 along the edge, and flushing hole groups are opened on the wall of the annular flushing pipe 11 . The flushing hole group includes one or more first flushing holes 111 for flushing the surrounding wall of the urinal 10 and one or more second flushing holes 112 for flushing the sinking bay 101 . The first flushing hole 111 is arranged on the side of the annular flushing pipe 11 and faces the peripheral wall of the urinal 10 , and the second flushing hole 112 is arranged at the bottom of the annular flushing pipe 11 and faces the sinking bay 101 .

[0030] The inside of the squatting pan ceramic body 1 is pro...

Embodiment 2

[0035] Such as Image 6 , Figure 7 As shown, the difference between the present embodiment and the first embodiment is only that the position of the water inlet 120 is higher than the position of the flushing hole group, and a block is fixed inside the water storage bay 12 to separate the water inlet 120 from the annular flushing pipe 11 Water baffles 121 on both sides. The top of the water baffle 121 is sealed and connected to the top wall of the water storage bay 12, and the bottom is provided with a flow gap 122 for connecting the water inlet 120 and the annular flushing pipe 11, and the position of the bottom end surface of the water baffle 12 is lower than that of the flushing hole group . The rest of the structures and principles of this embodiment are the same as those of Embodiment 1.

Embodiment 3

[0037] Such as Figure 8-10 As shown, the difference between this embodiment and the first embodiment is that the water storage space is an S-shaped delivery pipe 13, and the position of the water inlet 120 is lower than that of the flushing hole group. The bottom inlet of the S-shaped delivery pipeline 13 is connected to the water inlet 120 , and the top outlet faces the annular flushing pipeline 11 and is lower than the annular flushing pipeline 11 . The end face of the top outlet side of the S-shaped delivery pipeline 13 is inclined to the right and downwards and forms an obtuse angle α of 120-145° with the horizontal plane. The rest of the structure of this embodiment is the same as that of Embodiment 1.

[0038] The working principle of this embodiment is: under the normal water-stop state, the overflow device 6 isolates the outside air and communicates with the drain outlet of the drain valve 4 base through the overflow pipe 5 . The water stored in the S-shaped delivery ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com