Method for plugging sulfuric acid container leakage point under pressure

A container and leak point technology, applied in the direction of engine sealing, pipe/pipe joint/pipe fittings, engine components, etc., can solve the problems such as the need to stop production of leak points, reduce the stoppage time of acid production, etc., to ensure no sulfuric acid leakage, reduce The effect of acid production shutdown time and environmental pollution reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

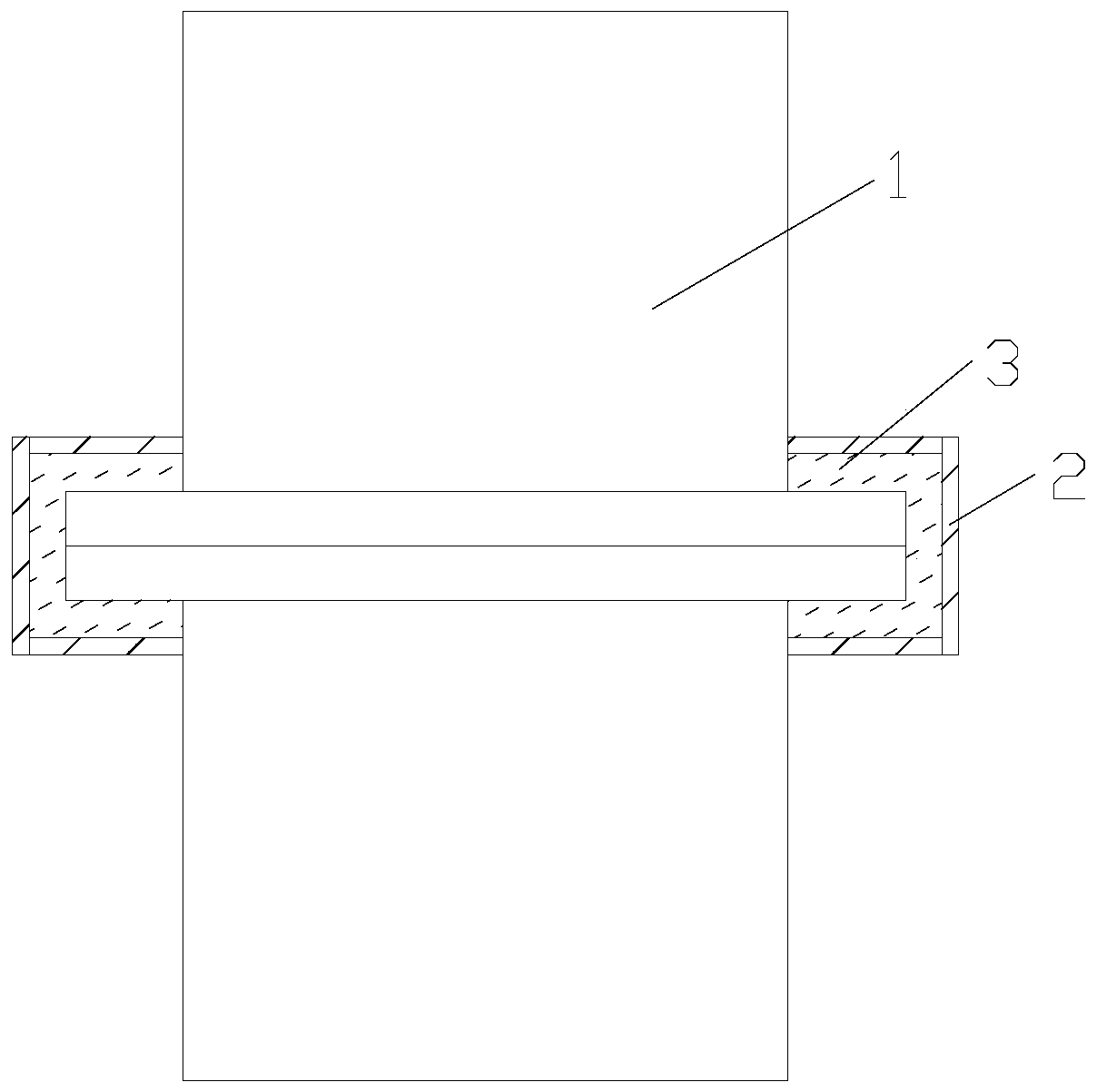

[0027] The leak point is the connection flange port of the upper and lower tower body of the sulfuric acid tower and the connection position between the upper tower body and the flange.

[0028] The method for plugging the leakage point of the sulfuric acid container under pressure comprises the following steps:

[0029] 1) Check to determine the size of the sulfuric acid leak in the container and the thinning area of the surrounding container wall.

[0030] 2) Make a repair cover. In order to control this leakage, the plugging plan is to block the connecting flanges of the upper and lower tower bodies and the connection position between the upper tower body and the flange as a whole, and make a ring-shaped repair cover with grooves. The groove can wrap the flange and the surrounding vessel wall thinning position;

[0031] 3) Clean up the leakage point and the surface of the surrounding container to expose the original surface of the sulfuric acid tower; for larger leakage ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com