Automatic calcium carbide stoking robot

A robot and calcium carbide technology, which is applied in the field of calcium carbide furnace slamming, can solve the problems of low degree of freedom, small operating range, and poor maneuverability of drill rods, and achieve the effects of improving production efficiency, reducing safety hazards, and improving operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

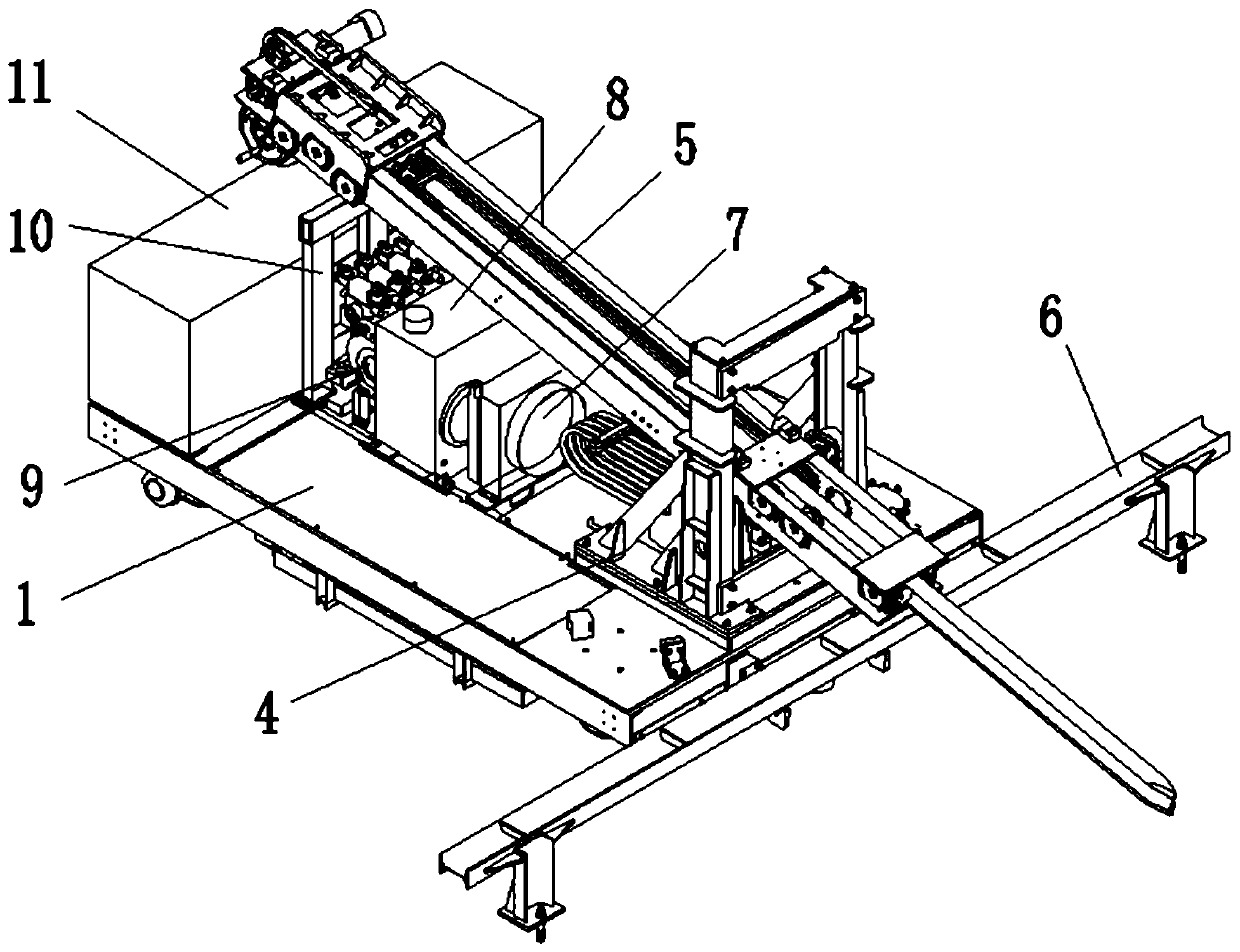

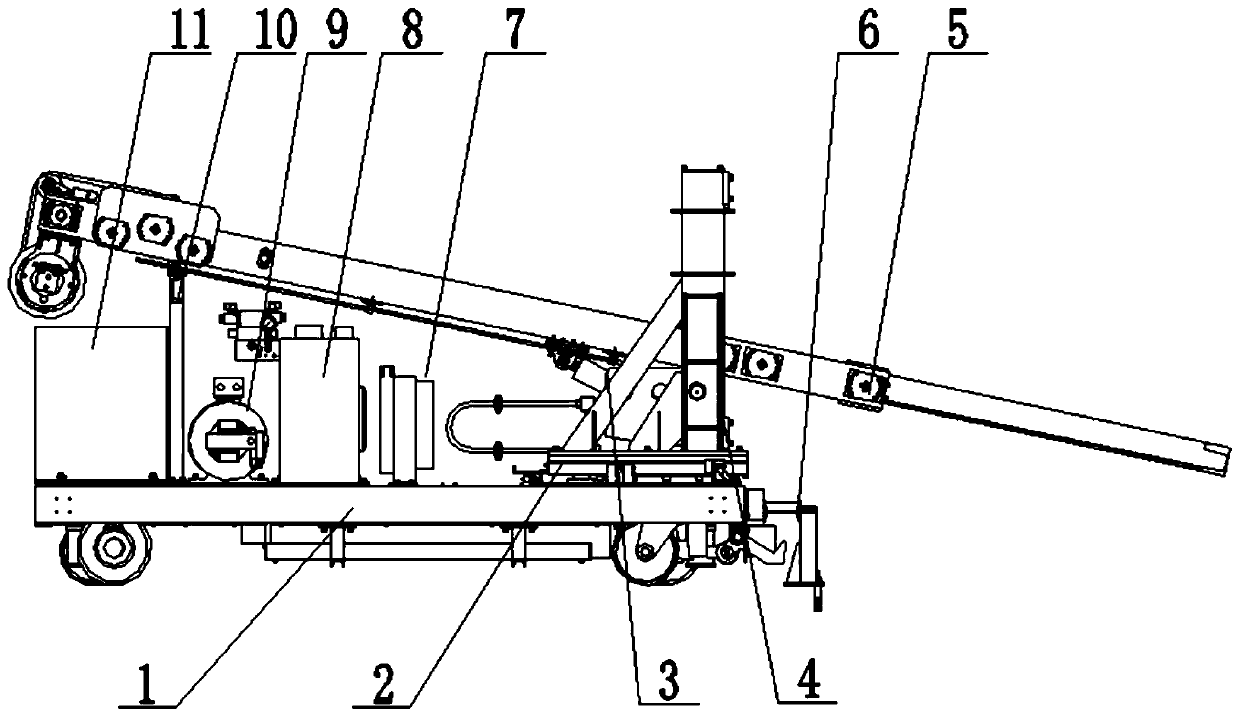

[0038] Such as Figure 1 to Figure 15 As shown, an automatic calcium carbide furnace robot according to the present invention includes a walking vehicle 1, a rotating mechanism 2, a pitch support mechanism 3, a lifting guide mechanism 4 and a drill rod driving mechanism 5;

[0039] The trolley 1 is provided with a rotary mechanism 2, the rotary mechanism 2 is provided with a lift guide mechanism 4, the pitch support mechanism 3 is slidably arranged on the lift guide mechanism 4, one end of the drill rod drive mechanism 5 is placed on the trolley 1, and the drill rod The middle part of the drive mechanism 5 is hinged with the pitch support mechanism 3 .

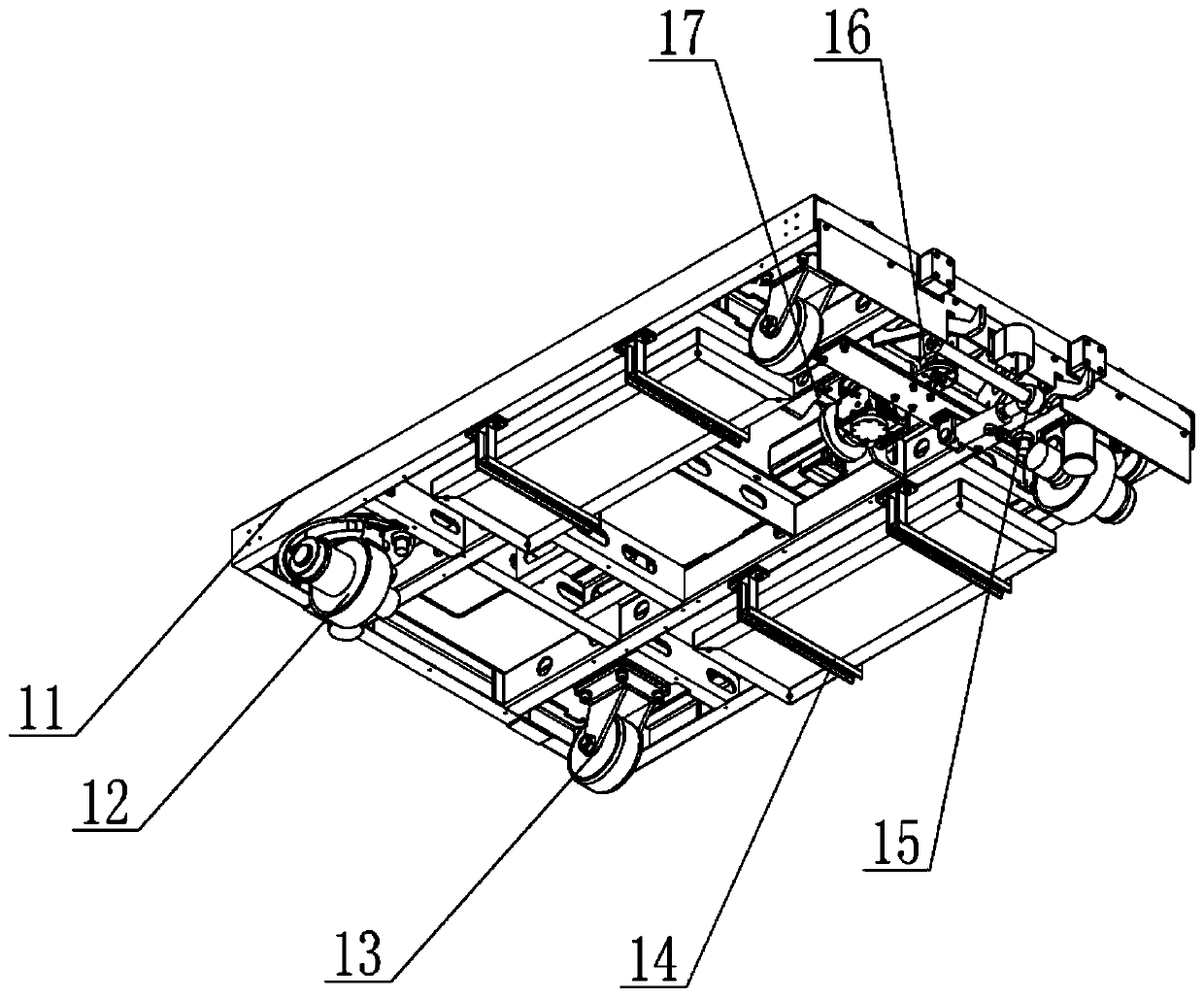

[0040] Further: the trolley 1 includes a vehicle frame, a steering wheel 12, a universal wheel 13, a battery support 14, a hydraulic hook mechanism 15, a press rotary joint 16 and a rotary dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com