Hybrid structure interferometer sensor for three-parameter measurement

A hybrid structure and interferometer technology, applied in the direction of converting sensor output, instruments, measuring devices, etc., can solve the problems of high price and complicated sensor manufacturing process, and achieve the effect of improving the sensitivity of the refractive index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

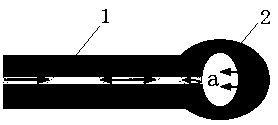

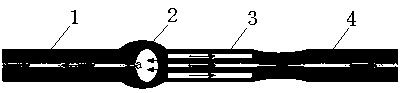

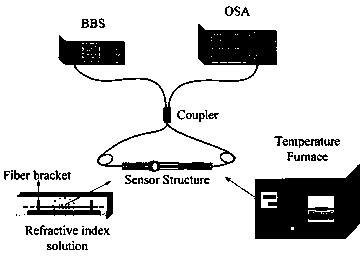

[0021] like figure 1 As shown, a hybrid structure interferometer sensor for three-parameter measurement in this embodiment includes a first single-mode optical fiber 1, a coreless optical fiber microsphere cavity 2, a photonic crystal optical fiber 3 and a second single-mode optical fiber fused sequentially from left to right. Mode fiber4.

[0022] When making this embodiment, firstly, the first single-mode optical fiber 1 is cut flat and ready for use, and then the first single-mode optical fiber 1 and the coreless optical fiber are fused by using an optical fiber fusion splicer. After fusion splicing, keep the coreless fiber at a length of 200 microns, and perform two arc discharges on the end of the coreless fiber on the fusion splicer, so that the silica layer at the end of the coreless fiber is fused together to form a coreless fiber microsphere cavity 2 , the coreless fiber microsphere cavity 2 is filled with air. The contact surface of the core of the first single-mod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com