Manufacturing method of metal film plated double-humped resonance liquid sensor based on SPR (Surface Plasmon Resonance)

A technology of liquid sensor and bimodal resonance, which is applied in the field of liquid sensor manufacturing to achieve the effect of long-distance telemetry, high performance-price ratio, and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings, but the present embodiments are not intended to limit the present invention, and all similar methods and similar changes of the present invention should be included in the protection scope of the present invention.

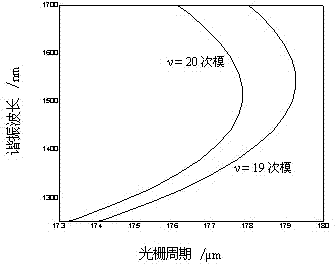

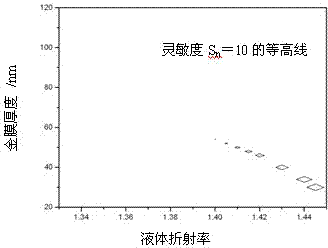

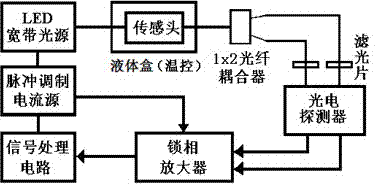

[0029] In order to maximize the change of the double peak spacing in the transmission spectrum of the metal-coated long-period fiber grating based on the SPR effect, it is necessary to select an appropriate grating period and metal film thickness to improve the sensor’s sensitivity to the liquid’s refractive index (or concentration). Monitor sensitivity. Therefore, there is a need for a novel method for manufacturing a metal-coated long-period fiber grating sensor. Compared with the traditional conductivity liquid sensor, the fiber grating liquid sensor has the characteristics of anti-electromagnetic interference, large dynamic r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com