Optical fiber Bragg grating sensor making method

A technology of fiber optic Bragg and grating sensors, which is applied in light guides, optics, instruments, etc., can solve the problems of inability to measure the thickness of microbial films online, and achieve high stability, high precision, and improved sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

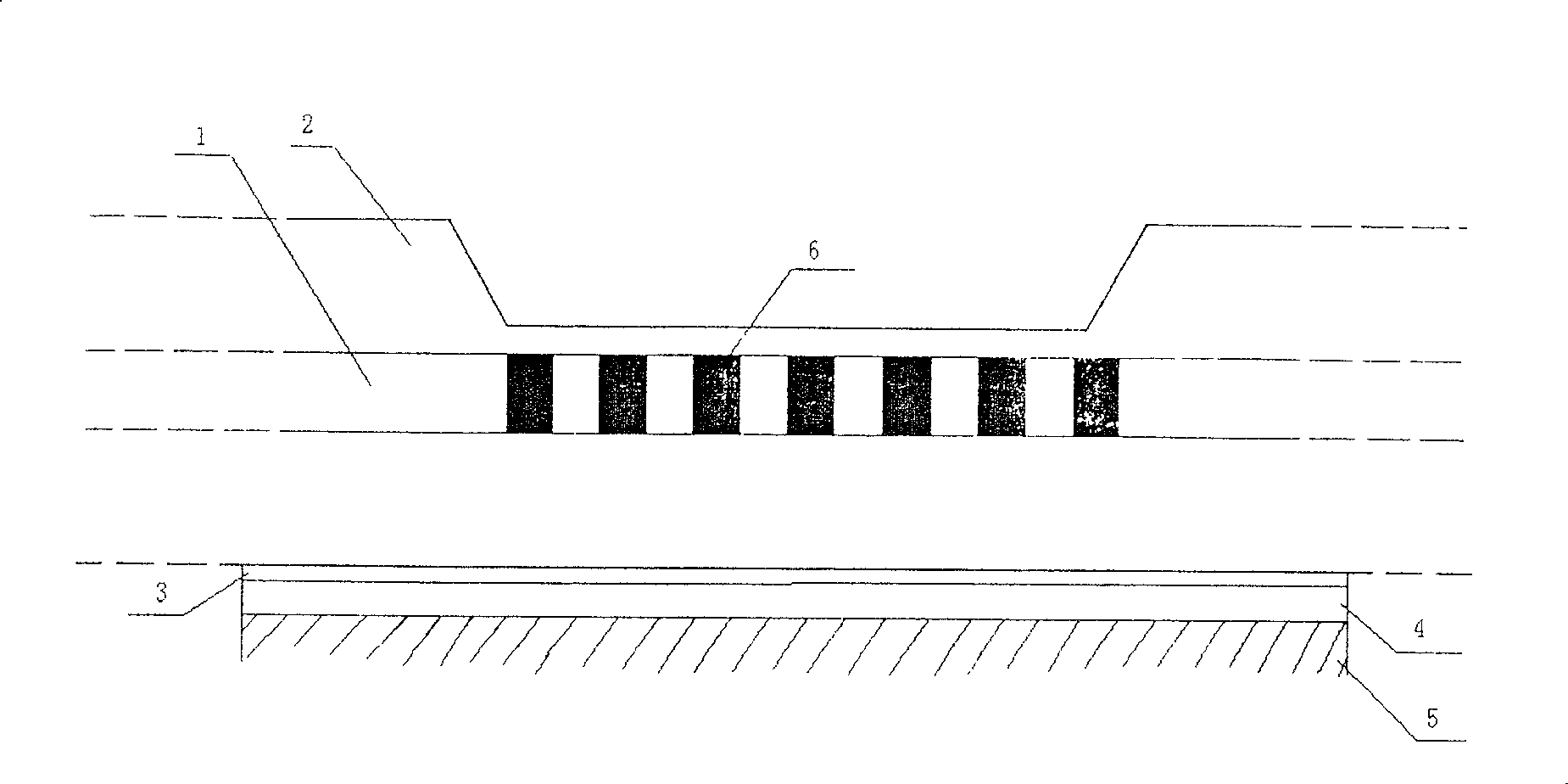

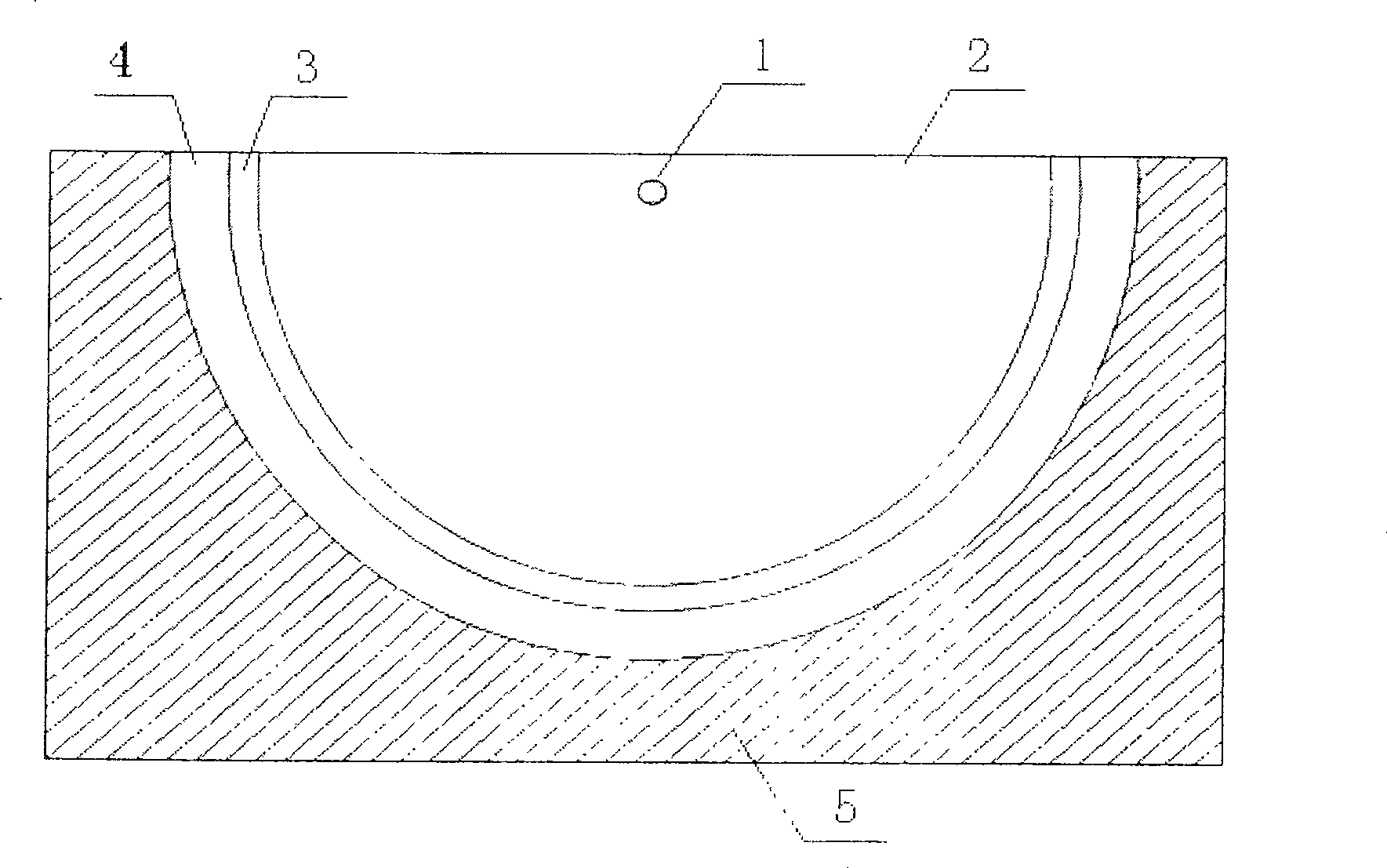

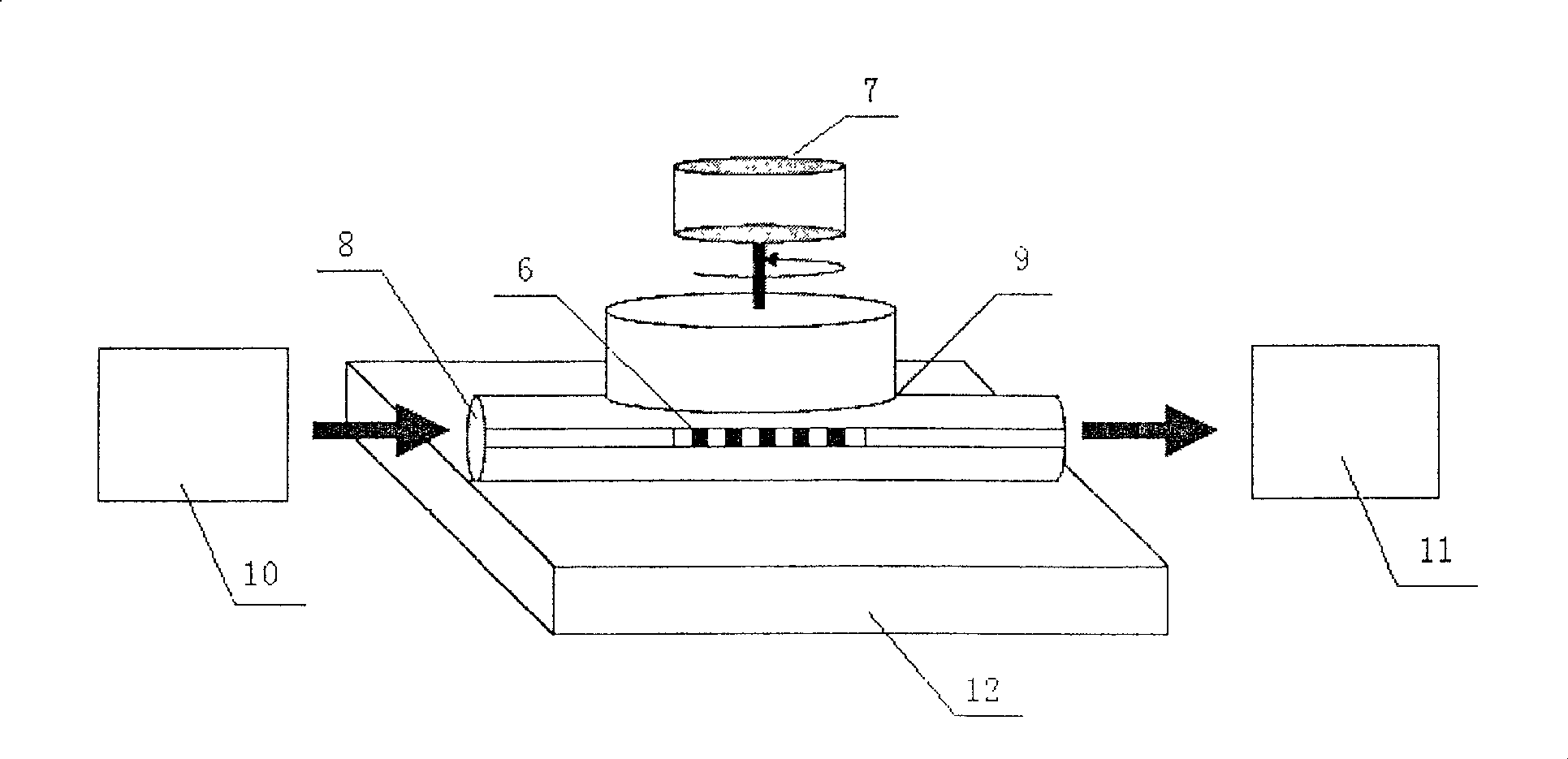

[0034] see figure 1 , figure 2 , image 3 , Figure 4, Figure 5 and Image 6 , a kind of manufacture method of fiber Bragg grating sensor, manufacture step is:

[0035] The first step: the making of fiber Bragg grating: select photosensitive single-mode fiber 8, described photosensitive single-mode fiber 8 is made up of fiber core 1, cladding 2 and fiber coating layer 3, selects the diameter of described fiber core 1 to be about 3 μm-4 μm, using phase template technology, using a KrF excimer laser as an ultraviolet light source to write a fiber Bragg grating 6 with a period of 0.530 μm and a grid number of 20,000 in the photosensitive single-mode fiber 8; during the writing process Among them, use a spectrum analyzer 11 with a wavelength range of 600nm-1700nm and a resolution greater than or equal to 0.01nm to monitor the resonance center wavelength and resonance peak intensity of the grating, and it is optimal when the reflectance of the resonance center wavelength is abov...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com