Automatic guided vehicle path planning method for routing inspection

An automatic guided vehicle and path planning technology, which is applied in the direction of motor vehicles, vehicle position/route/height control, non-electric variable control, etc. The effect of widening the product detection area, reducing labor costs, and improving the efficiency of the inspection system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below with reference to the drawings and embodiments. It can be understood that the specific embodiments described here are only used to explain the present invention, but not to limit the present invention. In addition, it should be noted that, for ease of description, the drawings only show a part but not all of the structure related to the present invention.

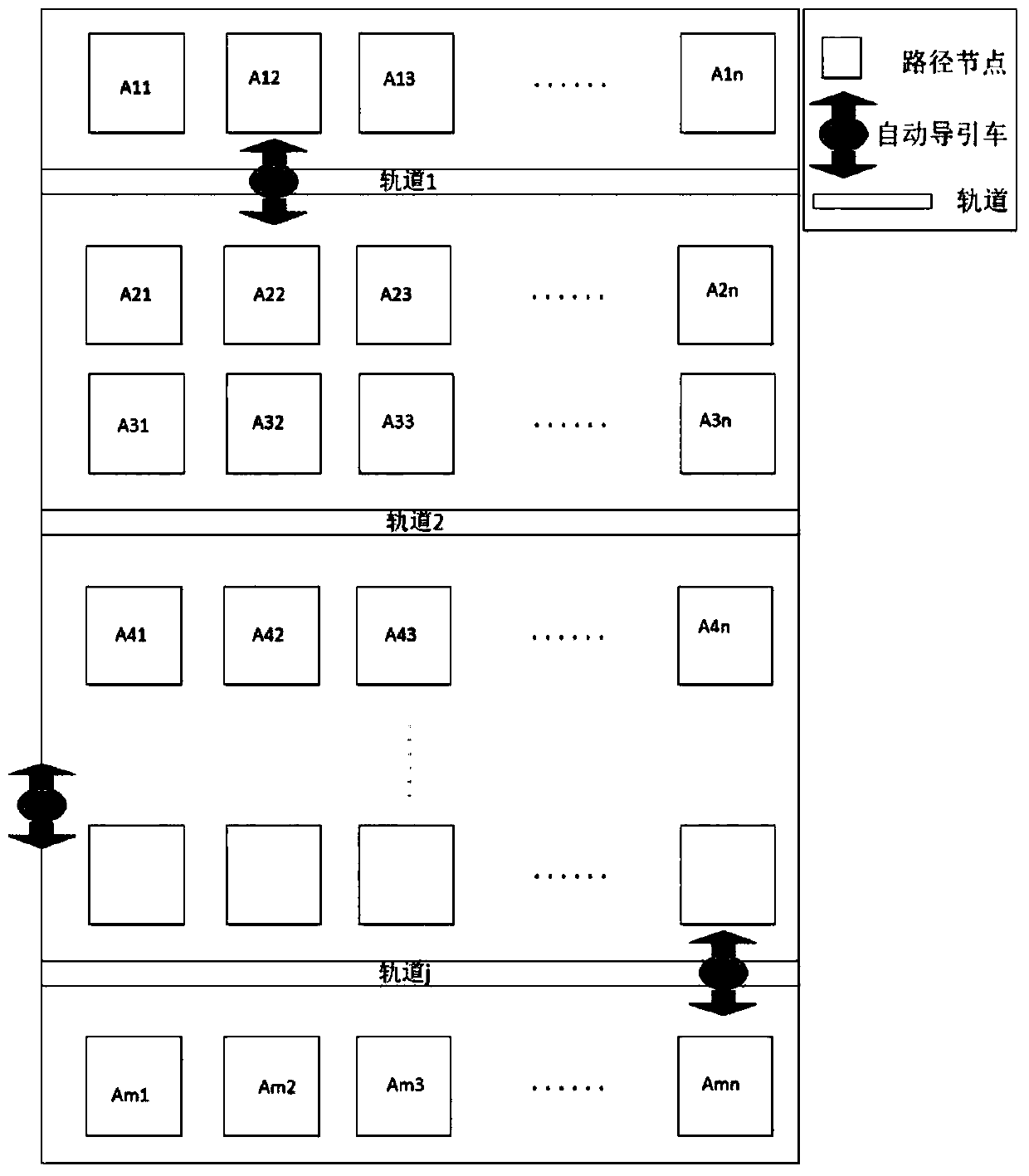

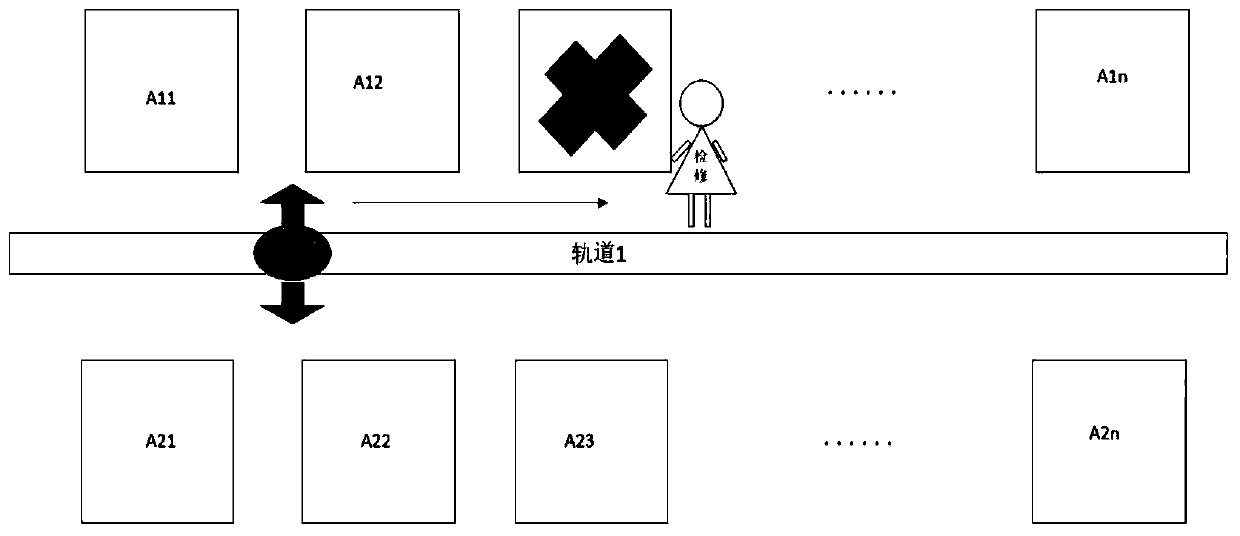

[0030] Aiming at the automatic inspection of textile weaving, the present invention proposes an automatic guided vehicle instead of manual inspection, especially a path planning method under a specific site.

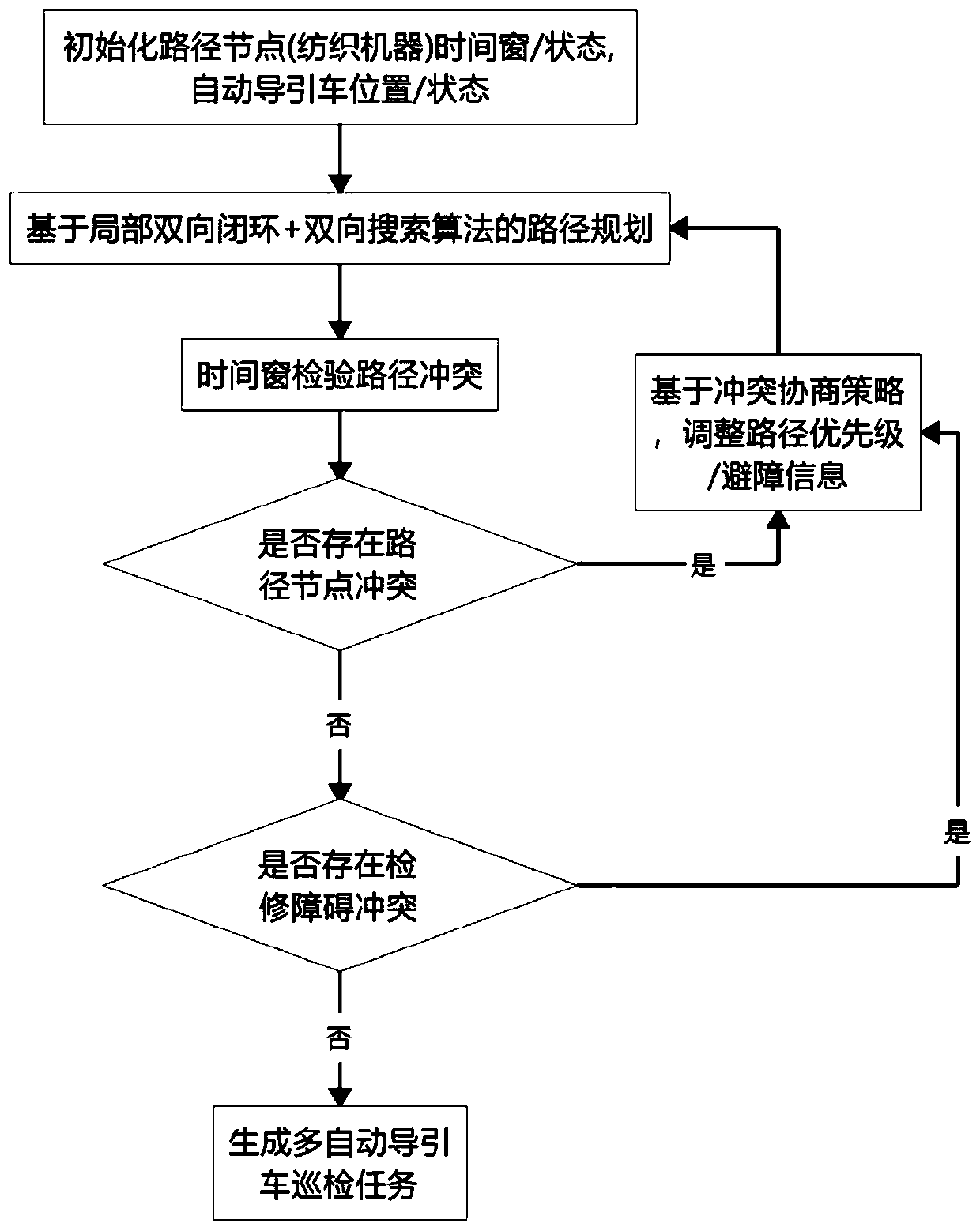

[0031] Firstly, the map is constructed by using topology modeling method according to the textile weaving inspection environment. A two-way breadth search algorithm based on the time factor, and a local two-way closed-loop method is designed to realize the global optimal path planning of multiple automatic guided vehicles and the path re-planning after...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com