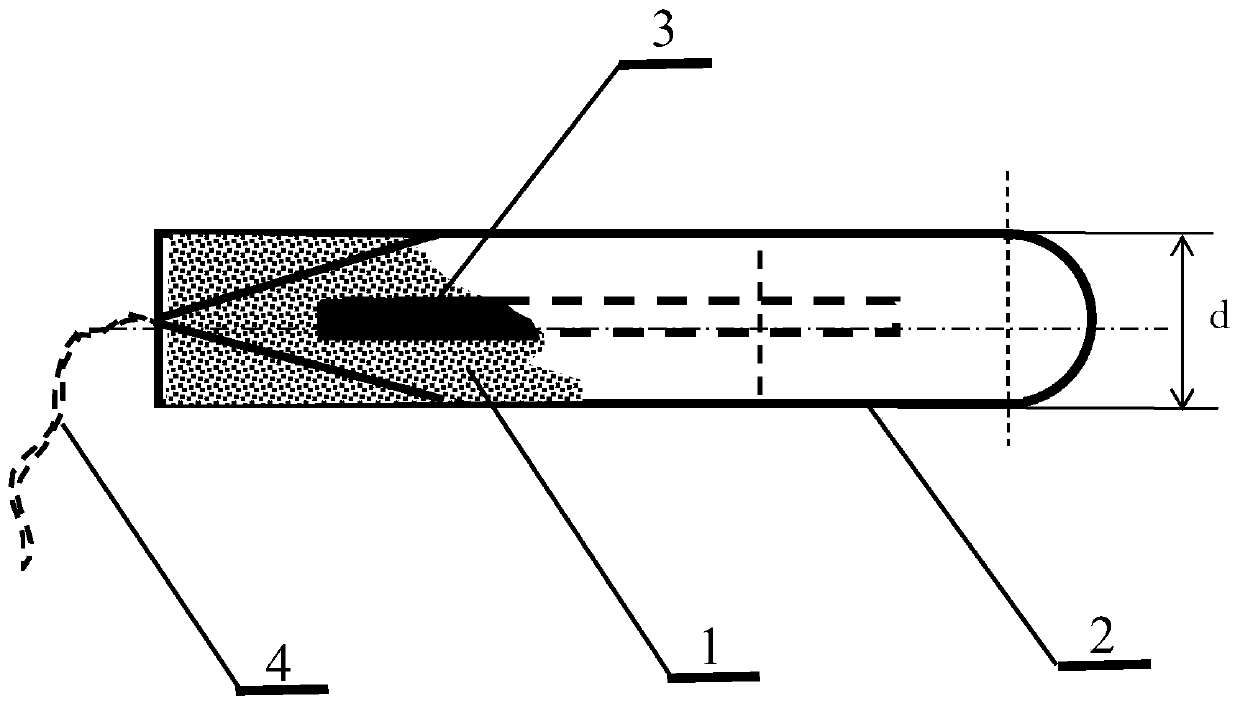

Anti-adhesive low-compression set polyurethane foam material for nasal hemostasis and preparation method of polyurethane foam material

A polyurethane foam and anti-adhesion technology is applied in the field of nasal medical consumables and its preparation, which can solve the problems of poor storage stability and inconvenient use, and achieve the effects of preventing adhesion, alleviating pain, and avoiding a decrease in comfort.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

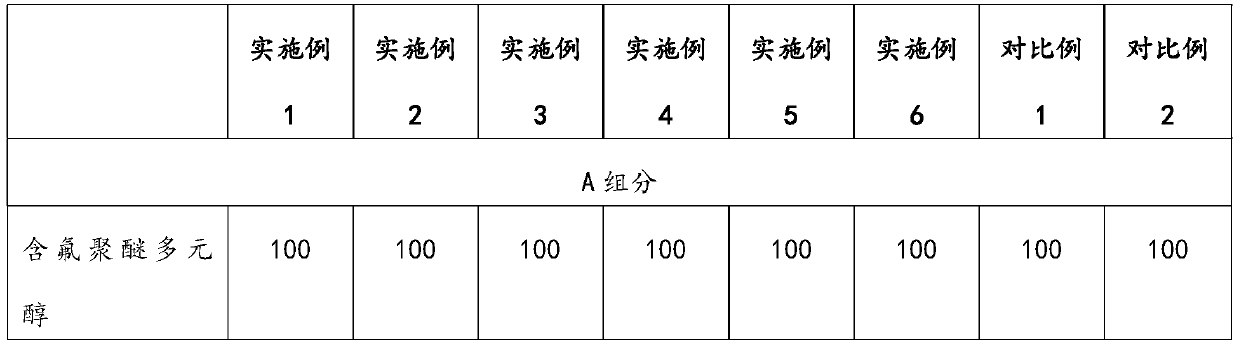

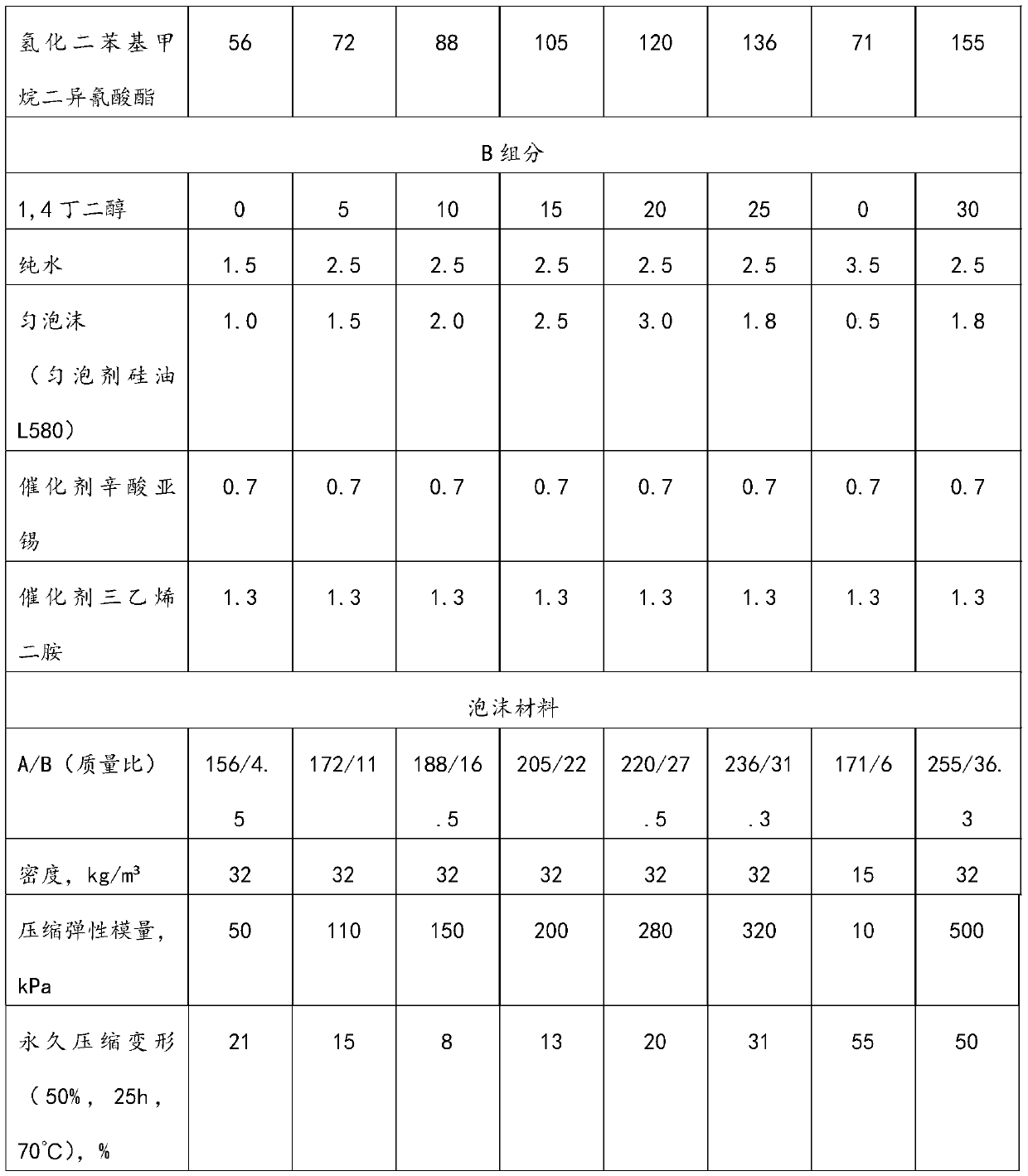

Embodiment 1-6

[0056] (1) Preparation of component A polyurethane:

[0057] A. Accurately weigh the fluorine-containing polyether polyol into the three-necked flask according to the addition amount of each component listed in Table 1, start stirring, and raise the temperature to 110°C, vacuumize (-0.098MPa), 2h, carry out Raw materials are refined and dehydrated.

[0058] B. Stop heating and cool down to 50°C, weigh and add hydrogenated diphenylmethane diisocyanate according to the addition amount in Table 1, and start stirring and mixing.

[0059] C. Heat up to 80-95°C and react for 3 hours.

[0060] D. Cool down to 50°C, stand still for 8 hours, and use as component A.

[0061] (2) Preparation of component B crosslinking agent:

[0062] A. According to component B listed in Table 1, add 1,4 butanediol, pure water, foam stabilizer silicone oil, stannous octoate catalyst and triethylenediamine catalyst in sequence.

[0063] B. Start stirring, raise the temperature to 50°C, and mix for 3 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com