Magnetic nanocomposite material, magnetic effervescent tablet and magnetic effervescent enhanced microextraction method and application

A composite material, magnetic nanotechnology, applied in the field of detection, can solve the problem of long time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

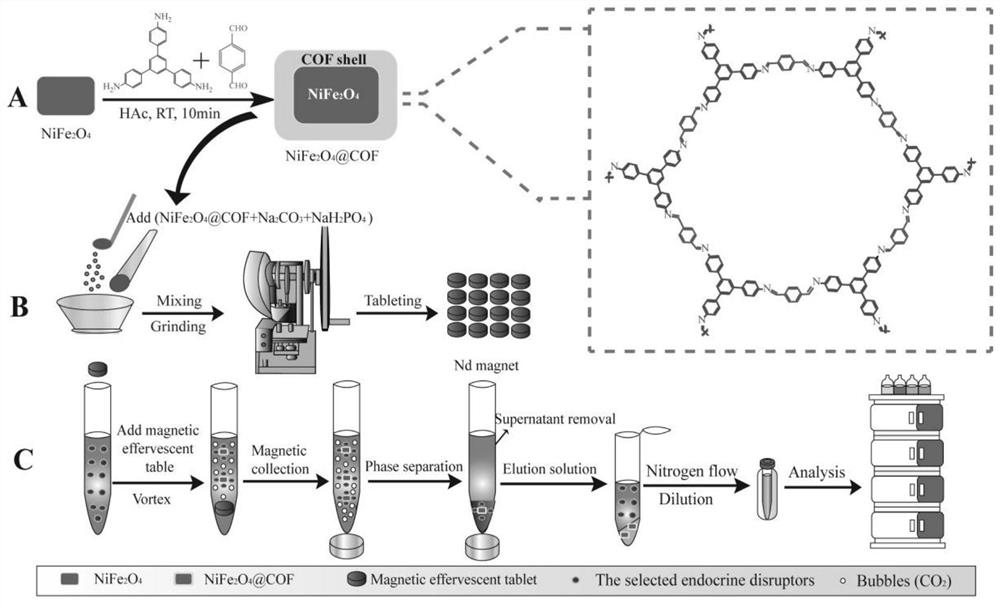

[0036] Embodiment 1: Based on NiFe 2 o 4 @COF's magnetic effervescence enhanced microextraction technology

[0037] Step 1: Magnetic Nanocomposite NiFe 2 o 4 Preparation of @COF

[0038] with FeCl 3 ·6H 2 O and NiCl 2 ·6H 2 O and urea were used as raw materials, dissolved in ultrapure water for 10-25min under strong magnetic stirring to dissolve completely, then the mixed solution was transferred to a stainless steel high-temperature and high-pressure reactor with a 100mL polytetrachlorethylene liner, and Place in a constant temperature drum drying oven, set the temperature at 160-180°C, and the reaction time is 9-16h; after the reaction is completed, cool to room temperature, collect the solid reactants with a magnet, and wash them with ultrapure water and ethanol in turn Three times, the obtained solid was dried in vacuum; after the sample was cooled to room temperature, it was ground and weighed, and finally marked as NiFe 2 o 4 magnetic nanoparticles.

[0039] N...

Embodiment 2

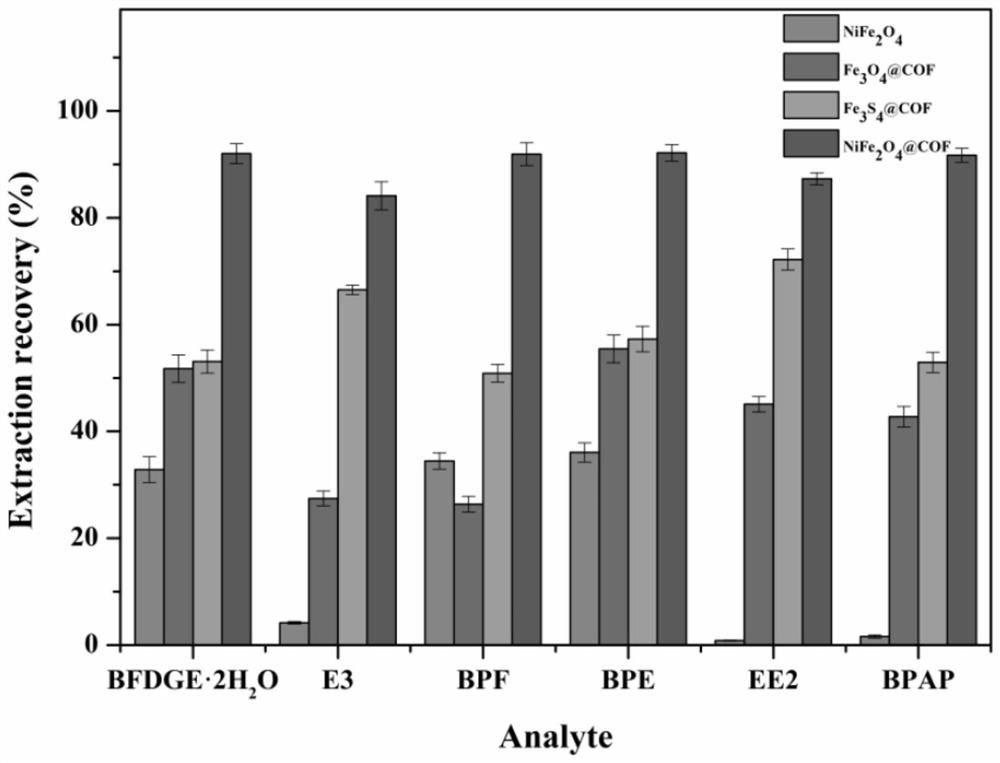

[0044] Example 2: Synthesized NiFe 2 o 4 , Fe 3 o 4 @COF、Fe 3 S 4 @COF and NiFe 2 o 4 Comparison of @COF extraction efficiency

[0045] Synthetic NiFe 2 o 4 , Fe 3 o 4 @COF、Fe 3 S 4 @COF and NiFe 2 o 4 The extraction efficiency of the six EDs by @COF was measured by the extraction recovery. Such as figure 2 As shown, in order to evaluate the extraction efficiency of EDs, the as-synthesized NiFe 2 o 4 、NiFe 2 o 4 @COF、Fe 3 S 4 @COF and Fe 3 o 4 @COF's ER. NiFe 2 o 4 @COF gives the highest average extraction recovery, for BFDGE 2H 2 The ERs of O, E3, BPF, BPE, EE2 and BPAP were 92.02%, 84.93%, 91.93%, 92.16%, 87.30% and 91.73%, respectively. The present invention studies the ERs of four different nanomaterials, from high to low: NiFe 2 o 4 @COF>Fe 3 S 4 @COF>Fe 3 o 4 @COF>NiFe 2 o 4 . Especially NiFe 2 o 4 , its ER for EE2, E3 and BPAP is less than 10%. These results indicate that all magnetic nanocomposites based on COFs can extract EDs ...

Embodiment 3

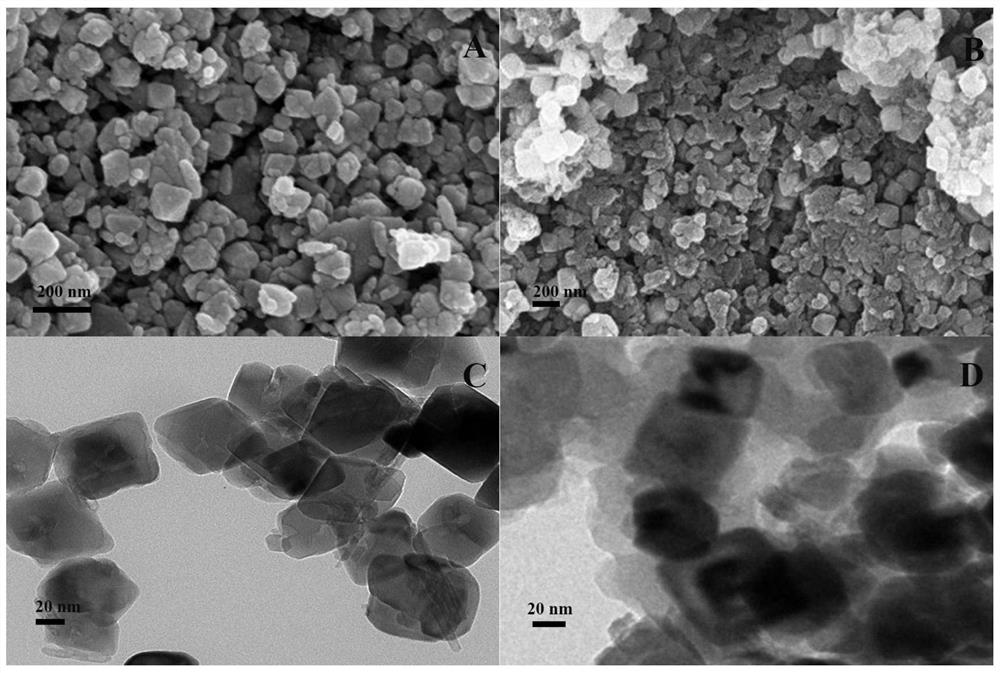

[0046] Example 3: NiFe 2 o 4 、NiFe 2 o 4 Characterization of @COF magnetic nanocomposites

[0047] NiFe 2 o 4 and NiFe 2 o 4 The SEM and TEM images of @COF magnetic nanocomposites are as follows image 3 A and 3C, image 3 Shown in B and 3D. At 30,000x magnification, bare NiFe 2 o 4 The magnetic nuclei are square and evenly dispersed. with NiFe 2 o 4 Compared to NiFe 2 o 4 Images of the @COF magnetic nanocomposite show subtle changes, indicating the formation of a polyimide network-like COF shell with a rough surface after polymerization. Therefore, it is proved that the COF shell has been successfully covered in NiFe 2 o 4 on the surface of nanoparticles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com