Method for preparing nano sulfur materials with different shapes based on H2O2 regulation

A technology of H2O2 and nano-sulfur, applied in the field of sulfur nanomaterials, can solve the problem of less research on the preparation method of layered sulfur nanosheets and sulfur nanorods, and achieve good multi-band PL emission characteristics, good stability, and easy availability of raw materials. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

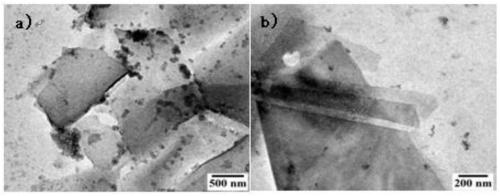

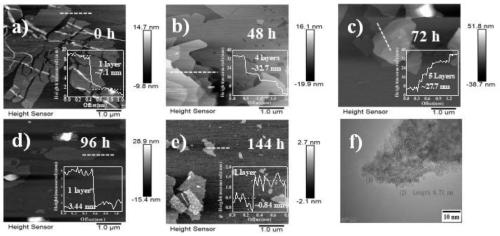

[0036] Embodiment 1 prepares nano-sulfur flakes

[0037] 1) Treat 3.4g of sublimated sulfur powder with nitric acid at 65°C for 54h, centrifuge and wash the precipitate four times; place the precipitate in a round bottom flask, add 50mL of deionized water and 6mL of polyethylene glycol PEG-600 at room temperature Stir for 40min to obtain a yellow suspension;

[0038] 2) Add 4.5 g of solid KOH to the yellow suspension mixture, stir at 85°C for 56 hours, the sulfur powder in the yellow suspension mixture is gradually dissolved by heating until the yellow suspension mixture turns into a red mixture;

[0039] 3) Cool the red mixture to room temperature; take 15mL of the red mixture, add 9mol / L, 2.3mL of H 2 o 2 While stirring, it can be observed that the red mixture turns into a light yellow transparent solution;

[0040] 4) Transfer the obtained light yellow transparent solution to a 100mL polytetrafluoroethylene reactor, and keep it in an oven at a temperature of 170° C. for ...

Embodiment 2

[0042] Embodiment 2 prepares nano-sulfur flakes

[0043] 1) Treat 1.4g of sublimated sulfur powder with nitric acid at 70°C for 48h, centrifuge and wash the precipitate three times; place the precipitate in a round bottom flask, add 50mL of deionized water and 4mL of polyethylene glycol PEG-400, at room temperature Stir for 30min to obtain a yellow suspension mixture;

[0044] 2) Add 4 g of solid NaOH to the yellow suspension mixture, stir at 70°C for 24 hours, the sulfur powder in the yellow suspension mixture is gradually dissolved by heating until the yellow suspension mixture turns into a red mixture;

[0045] 3) Cool the red mixture to room temperature; take 15mL of the red mixture, add 9.8mol / L, 2.1mL of H 2 o 2 , while stirring, it can be observed that the red mixed solution turns into a light yellow transparent solution;

[0046] 4) Transfer the obtained light yellow transparent solution to a 100 ml polytetrafluoroethylene reaction kettle, and keep it in an oven at ...

Embodiment 3

[0047] Embodiment 3 prepares nano-sulfur flakes

[0048] 1) Treat 1.0g of sublimated sulfur powder with nitric acid at 80°C for 40h, centrifuge and wash the precipitate three times; place the precipitate in a round bottom flask, add 50mL of deionized water and 6mL of polyethylene glycol PEG-200, at room temperature Stir for 25min to obtain a yellow suspension;

[0049] 2) Add 3.5 g of solid NaOH to the yellow suspension mixture, stir at 60°C for 72 hours, the sulfur powder in the yellow suspension mixture is gradually dissolved by heating until the yellow suspension mixture turns into a red mixture;

[0050] 3) Cool the red mixture to room temperature; take 15mL of the red mixture and add 10mol / LH dropwise to it 2 o 2 1.8mL, while stirring, it can be observed that the red mixture turns into a light yellow transparent solution;

[0051] 4) The obtained light yellow transparent solution was transferred to a 100 ml polytetrafluoroethylene reactor, and kept in an oven at a temper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap