Movable jaw supporting mechanism and jaw crusher

A technology of supporting mechanism and movable jaw, applied in the field of mining machinery, can solve the problems of increased manufacturing cost, weight and volume, increased manufacturing, assembly, transportation cost, increased weight and volume of eccentric shaft, etc. The effect of reducing the weight of the equipment and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

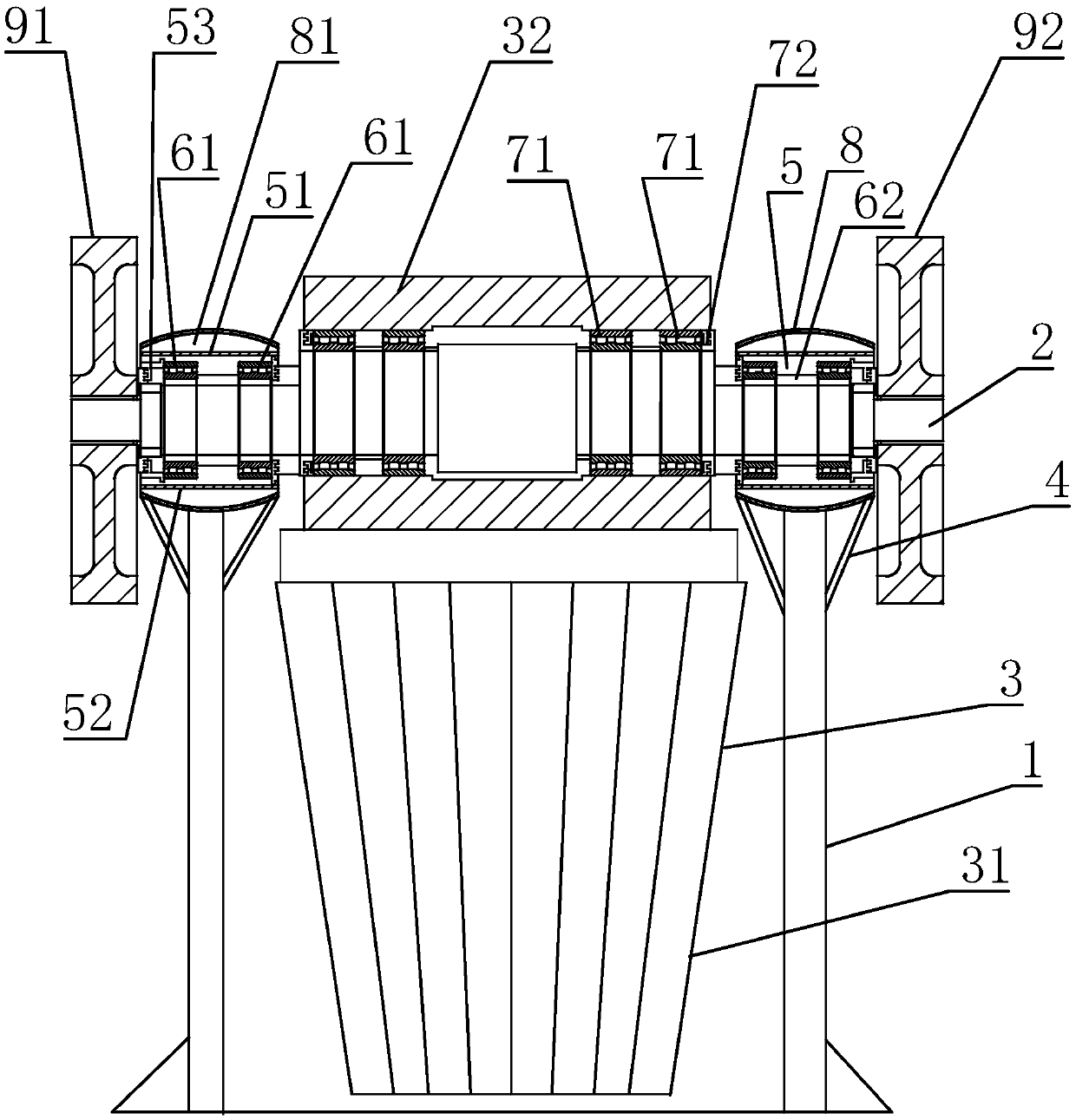

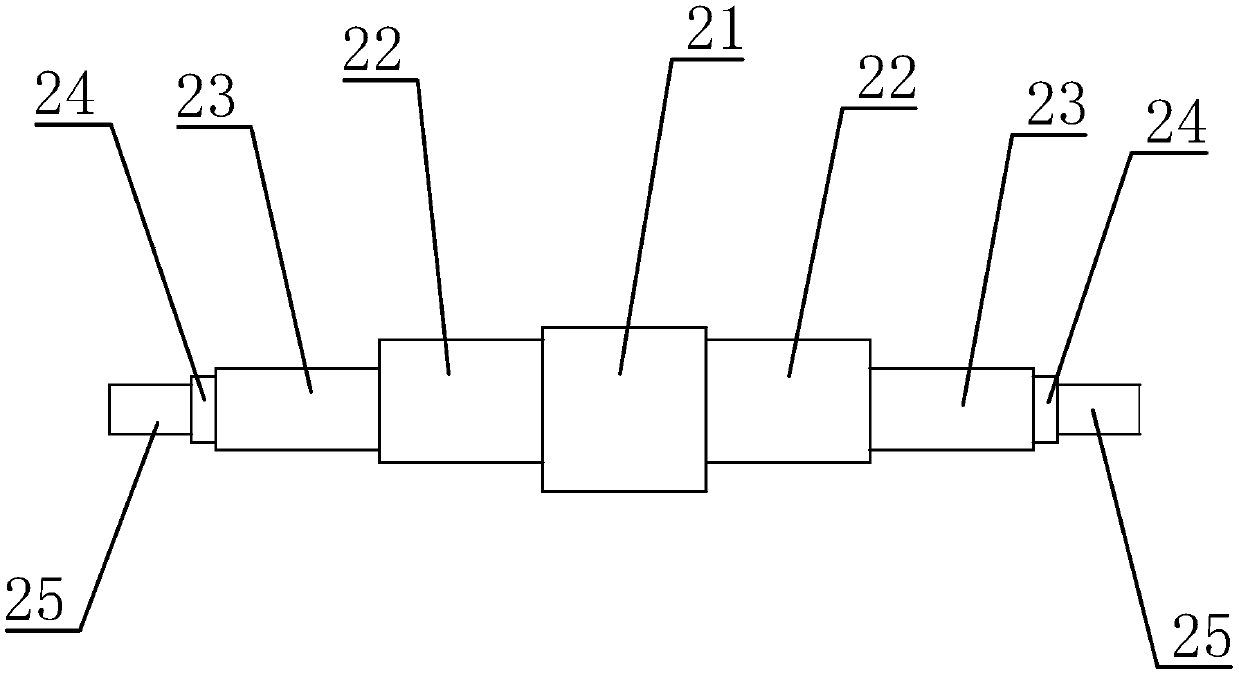

[0028] Embodiment one, see figure 1 , figure 2 , a movable jaw support mechanism, including a frame 1, an eccentric shaft 2 erected on the frame 1, and a movable jaw 3 pivotally connected to the eccentric shaft 2, the eccentric shaft 2 includes a connecting section 21 and is symmetrically connected in turn The eccentric section 22, the supporting section 23, the locking section 24, and the transmission section 25 at the two ends of the section 21, the axis lines of the supporting section 23, the locking section 24, and the transmission section 25 are located on the rotation centerline of the eccentric shaft 2, and the eccentric The axis line of the section 22 is located on the eccentric center line of the whole shaft of the eccentric shaft 2; two supporting parts are arranged symmetrically on the frame 1, and the supporting parts 23 on each side are erected on the supporting parts through two frame bearings 61; The support parts are all provided with a bearing box 5 for supp...

Embodiment 2

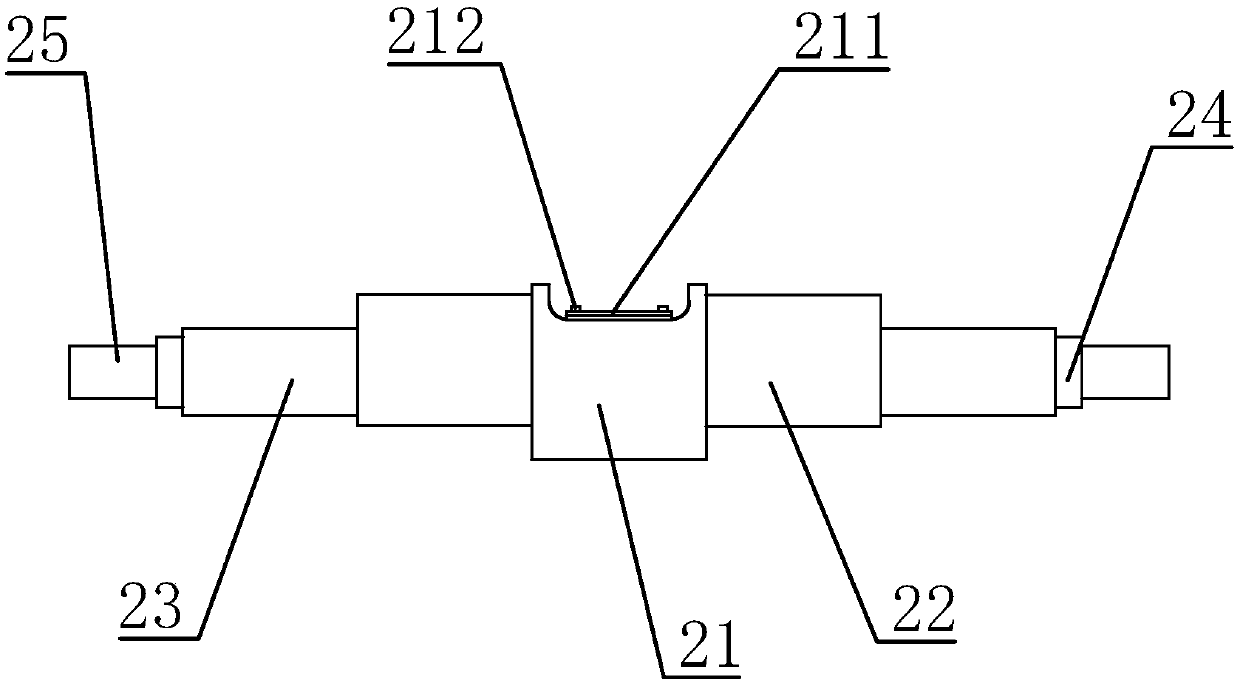

[0029] Embodiment two, see image 3 , the difference from Embodiment 1 is that the eccentric shaft 2 of the movable jaw support mechanism has a self-balancing function, and a cutting plane is provided on the connecting section 21 of the eccentric shaft 2, and the cutting plane is the same as the eccentric side of the eccentric section 22. On the side, the center line of the cutting plane is located on the plane where the eccentric center line of the eccentric section 22 and the rotation center line of the support section 23 are located, and the eccentric moment of the connecting section 21 is equal to the eccentric moment of the eccentric section 22; A counterweight 211 is also provided, and the counterweight 211 is locked by an adjusting screw hole and an adjusting bolt 212. The adjusting screw is located on the plane where the center line of the cutting plane is located, and the entire connection can be made by superimposing or reducing the counterweight 211. The center of m...

Embodiment 3

[0030] Embodiment three, see Figure 4 , the difference from Embodiment 1 is that three fine-tuning holes 213 are arranged on the center line of the cutting plane of the connecting section 21, and the fine-tuning holes 213 are equipped with fine-tuning bolts 214, and the fine-tuning bolts 214 equipped with the middle fine-tuning holes 213 The arrangement is symmetrical on both sides of the reference, and the settings of the fine-tuning holes 213 and the fine-tuning bolts 214 can fine-tune the centroid of the connecting section 21 to achieve precise balance of the eccentric moment of inertia, and an odd number can easily achieve equal distribution on both sides.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com