Intelligent oil film bearing oil supply monitoring sensing joint

An oil film bearing and oil supply technology, which is applied in the field of intelligent oil film bearing oil supply monitoring and sensing joints, can solve the problems of low heat resistance of shaft sleeves and tapered bushings, burden of unit shutdown, damage, etc., and achieves a compact and lightweight shape and structure. , The effect of stable transmission performance and good anti-interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

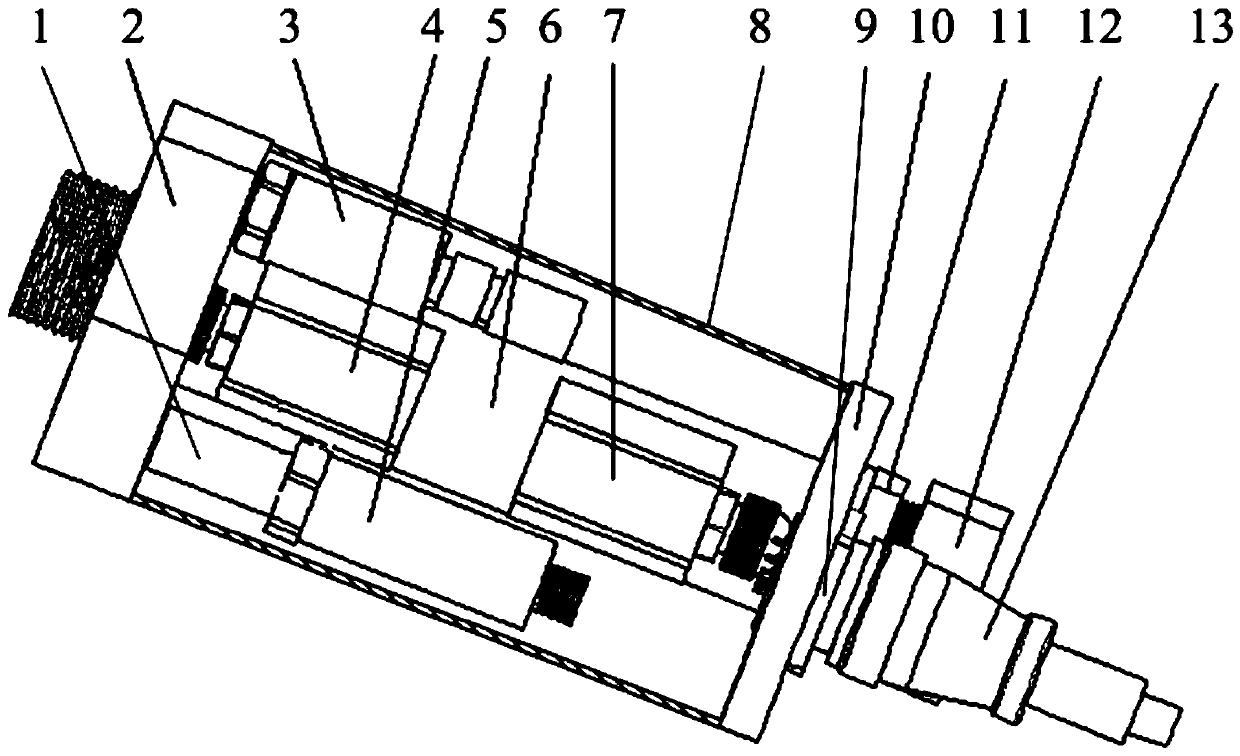

[0027] Please combine figure 1 As shown, an intelligent oil film bearing oil supply monitoring sensor joint provided by the present invention includes: a hose, a hard pipe on the rolling machine hydraulic line, and a remote central control room. The above is a part of the prior art. No longer. Different from the prior art, it also includes: a sleeve 8, the two ends of the sleeve 8 are respectively connected with a left end cover 2 and a right end cover 10, and the left end cover 2 has an outlet, which is connected with the rolling machine pressure The hard pipe connection on the pipeline, the right end cover 10 is tightly pressed against the end of the sleeve 8 through the locking effect of the lock nut 11, and the right end cover 10 is provided with an aviation joint 13, a movable nut 12 and a connector base 9. The movable ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com