A stamping die set and its working method

A stamping die and stamping head technology, applied in the field of die manufacturing technology and stamping die, can solve the problems of sheet fracture and non-brittle sheet protection, and achieve the effect of preventing fracture and preventing fracture and improving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will now be described in detail with reference to the accompanying drawings, and these figures are schematically illustrated, and only the basic configuration of the present invention is illustrated in a schematic manner, and therefore it is shown only related to the present invention.

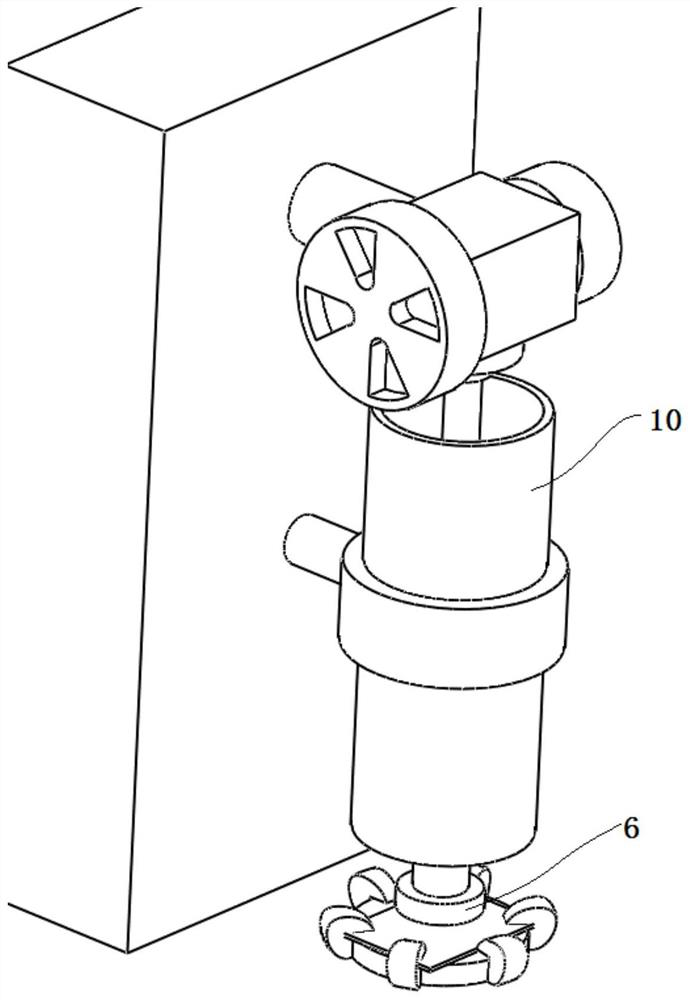

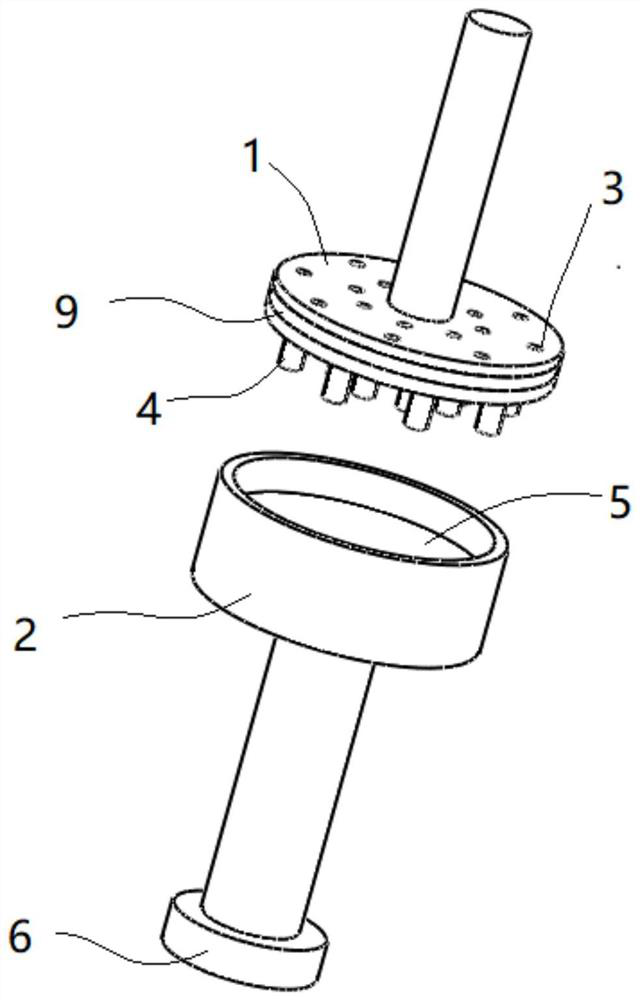

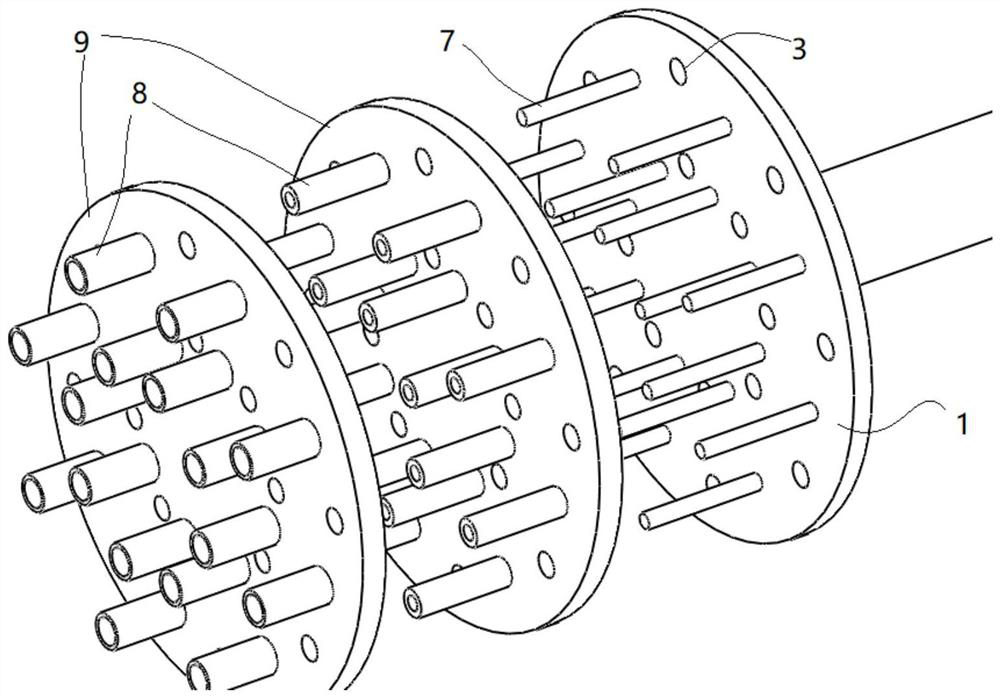

[0027] figure 1 A schematic structural diagram of a stamping bucket 10 is shown, and a stamping module comprising: a stamping tub 10 having a driving mechanism, a mold cavity, a mold cavity, a cavity, a cavity, The surface of the cavity is provided with a sheet, and the upper pressure plate 1 and the lower pressure plate 2 connected by the rope 10, the upper press plate 1 and the lower pressure plate 2 can be subjected to a rushing bucket 10 in the stamped bucket 10; There is a through hole 3, and a plurality of top posts 4 are provided at the lower surface of the upper pressure plate 1, the free end end of the top post 4 is flat; the upper surface of the lower pressu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com