Radial sealing type full-automatic material cover and material transport vehicle

A radial sealing and fully automatic technology, applied in the direction of transportation and packaging, containers, packaging, etc., can solve the problems of easy safety accidents and overall cost increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

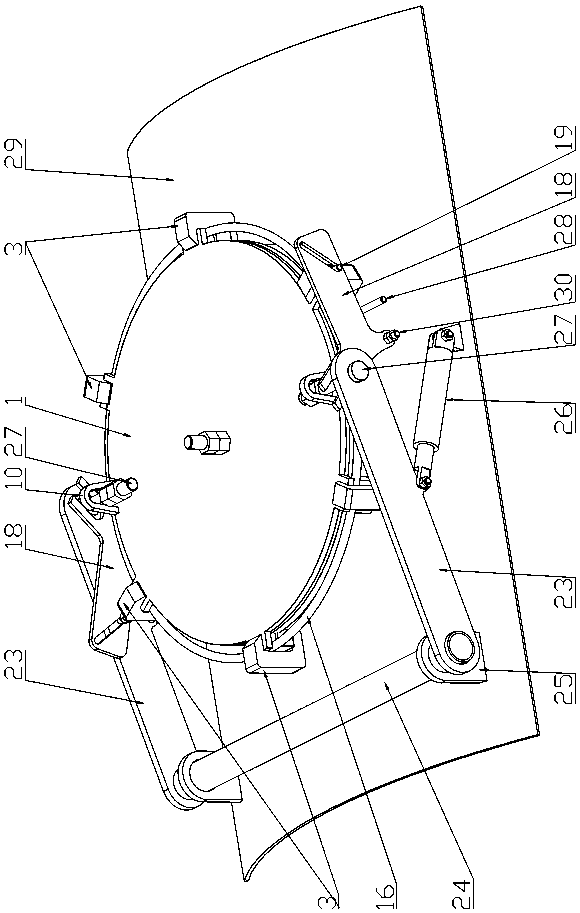

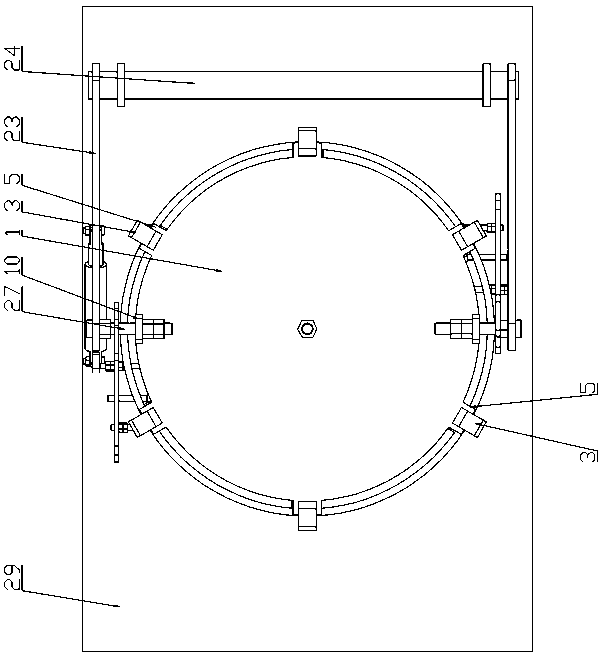

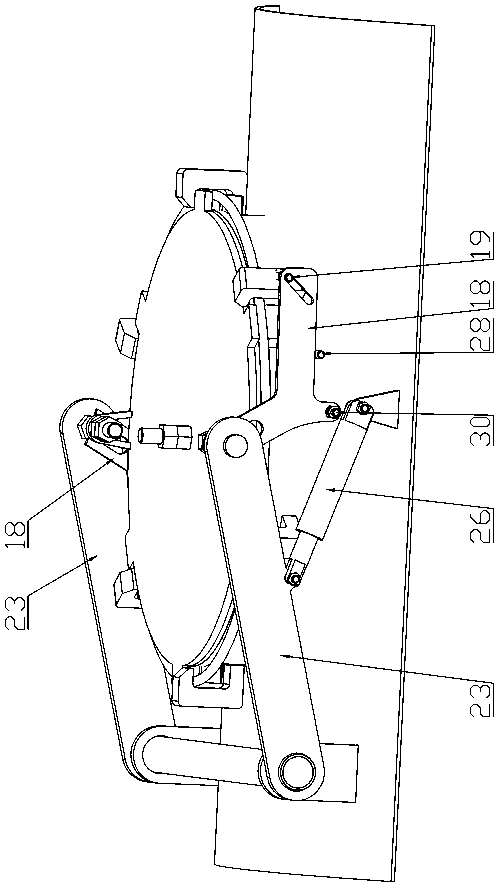

[0038] Such as Figure 1~Figure 10 As shown, a radially sealed fully automatic material cover includes a material cover 1, a discharge opening ring 2, a drive unit, a locking hook 3 and a linkage mechanism.

[0039]The material cover 1 comprises a material cover upper plate 4 and a material cover lower plate 7, the outer periphery of the material cover upper plate 4 is provided with an upper limit plate that is annular and spaced apart, and the radial two ends of the upper end surface of the material cover upper plate are equipped with Suspension hook 10, suspension hook 10 is provided with first guide hole 11, and the lower end surface of material cover upper plate 4 is equipped with upper pressure ring 6, and the upper end surface of material cover lower plate 7 is equipped with lower retaining ring 9, surrounds lower retaining ring 9 The first sealing ring 8 arranged on the outside, the first sealing ring 8 is a hollow sealing ring, the diameter of the upper plate 4 of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com