Silicon wafer surface defect visual detection device and detection method

A visual inspection device and a technology for the surface of silicon wafers, which are used in measurement devices, optical testing of flaws/defects, and material analysis by optical means. It can solve problems such as inability to obtain silicon wafers accurately, reduce manual intervention, and improve the success rate. and efficiency, the effect of high practical value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065] A silicon wafer surface defect visual detection device and detection method of the present invention will be described in detail below in conjunction with the embodiments and the accompanying drawings.

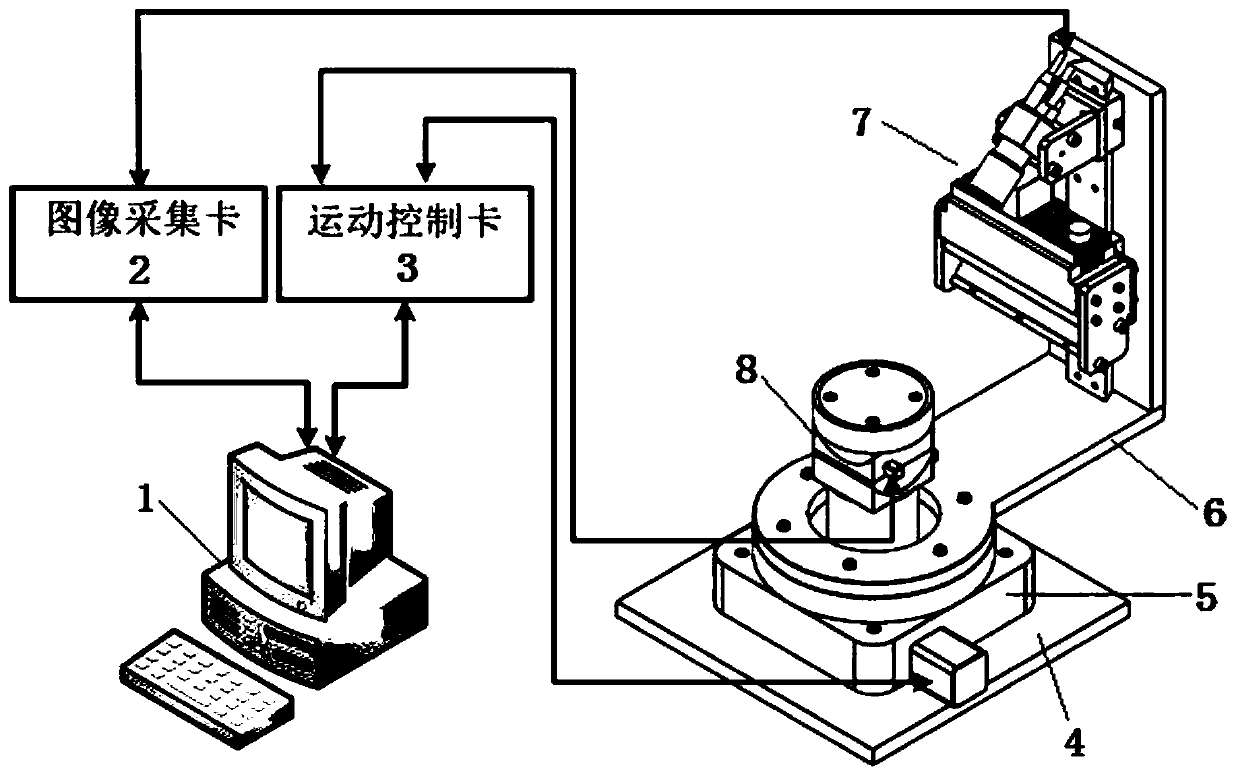

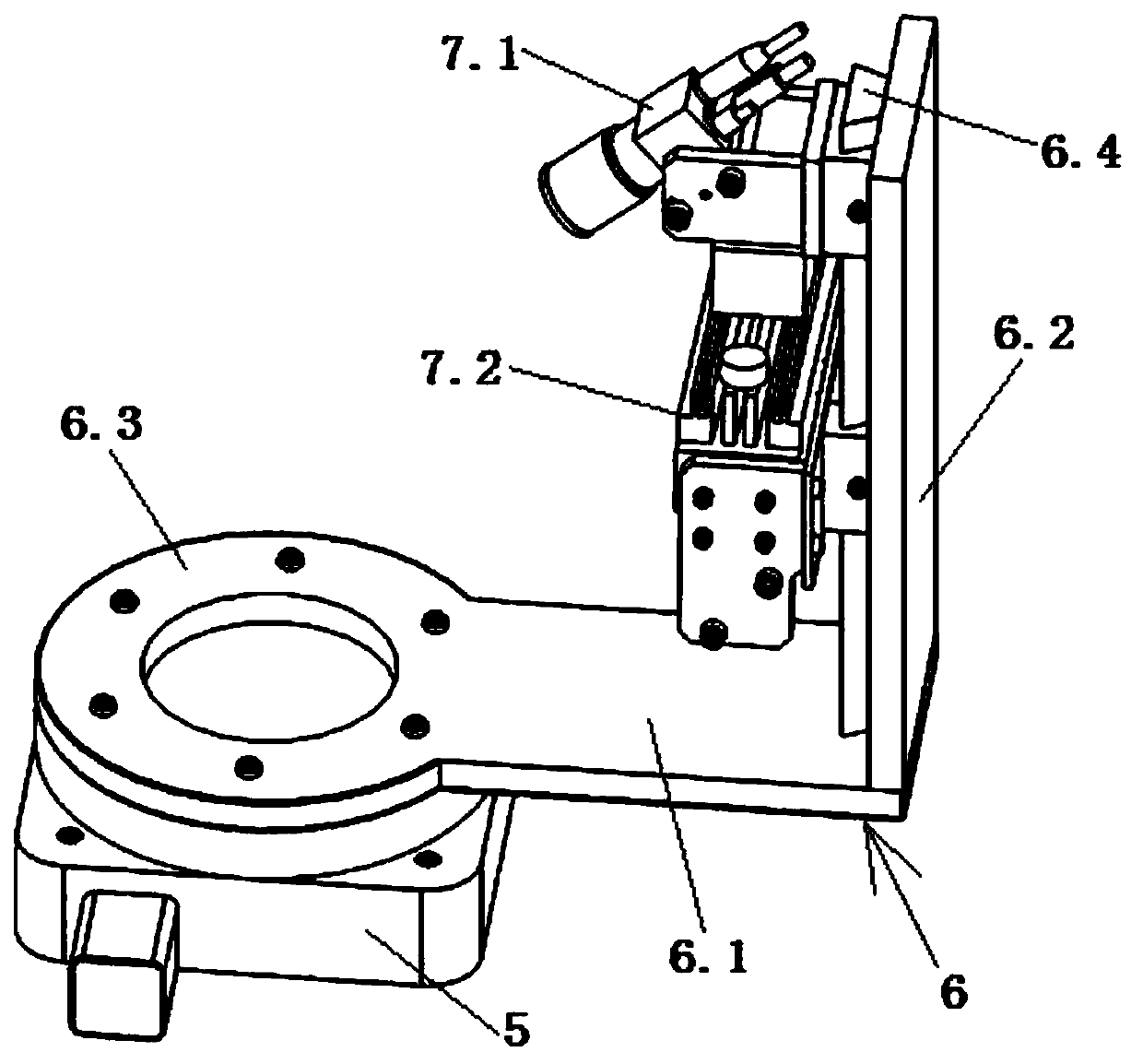

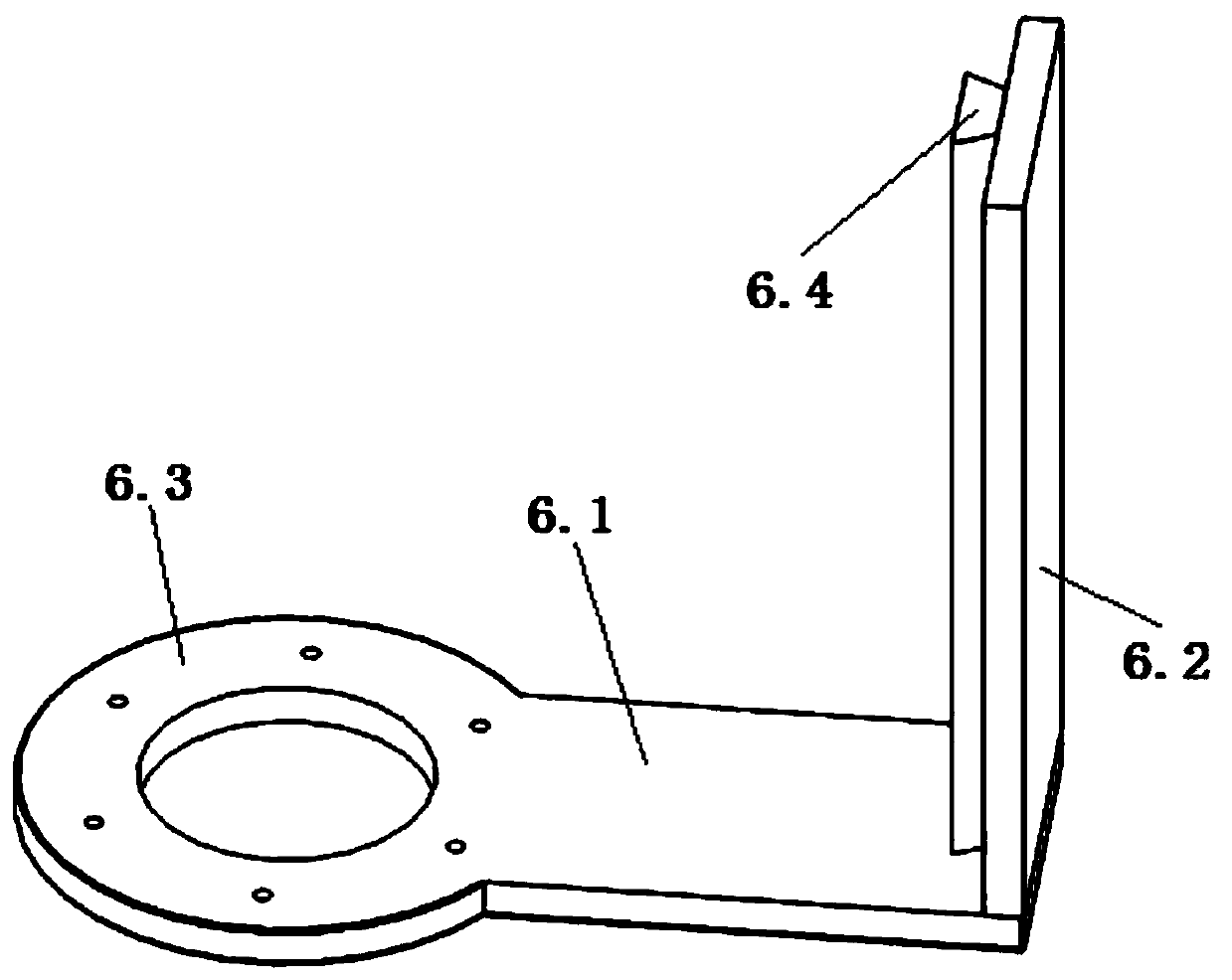

[0066] Such as figure 1 As shown, a visual detection device for silicon wafer surface defects of the present invention includes a computer 1, an image acquisition card 2 and a motion control card 3 connected to the computer 1 respectively, and the image acquisition part of the computer 1 passes through the image acquisition card 2 Connect the lighting and imaging unit 7, the drive control part of the computer 1 is respectively connected to the silicon wafer carrier 8 and the hollow electric rotary table 5 through the motion control card 3, wherein the hollow electric rotary table 5 is fixed on the machine platform 4 , and connect the illumination imaging unit 7 through the L-shaped connection bracket 6 fixed on the hollow electric rotary table 5, for driving the illumin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com