A Registration Method of Aircraft C-Beam Based on Local Invariance

An aircraft and registration technology, which is applied in graphics and image conversion, image analysis, image enhancement, etc., to achieve the effects of ensuring registration accuracy and method reliability, solving technical problems, and high application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] In order to better understand the technical content of the present invention, specific embodiments are given together with the attached drawings for description as follows.

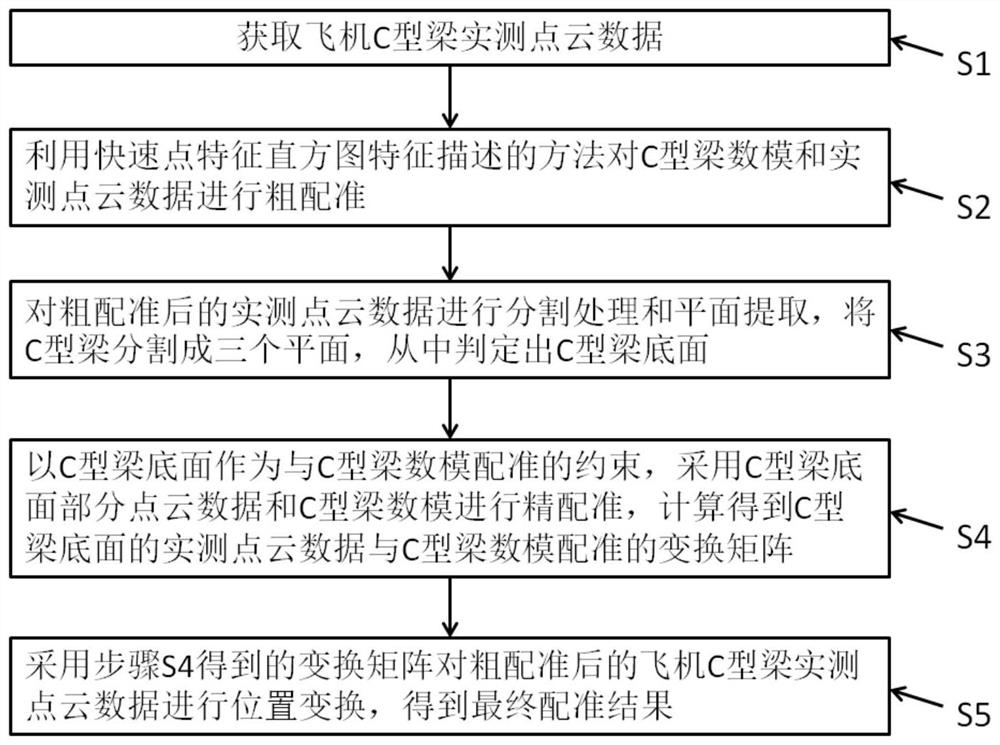

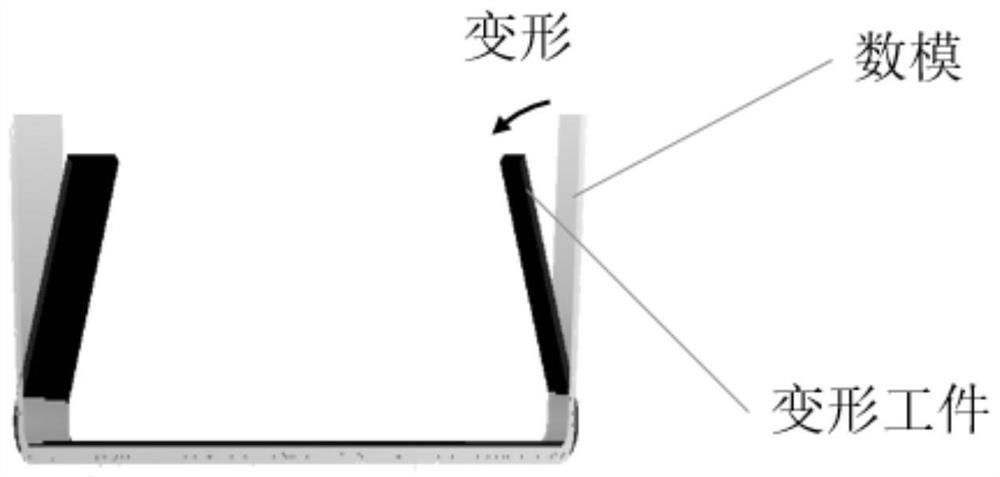

[0050] combine figure 1 , the present invention proposes a local non-deformable aircraft C-beam registration method, which is especially suitable for deformed aircraft C-beam workpieces. The registration method includes:

[0051] S1, obtain the measured point cloud data of the aircraft C-beam.

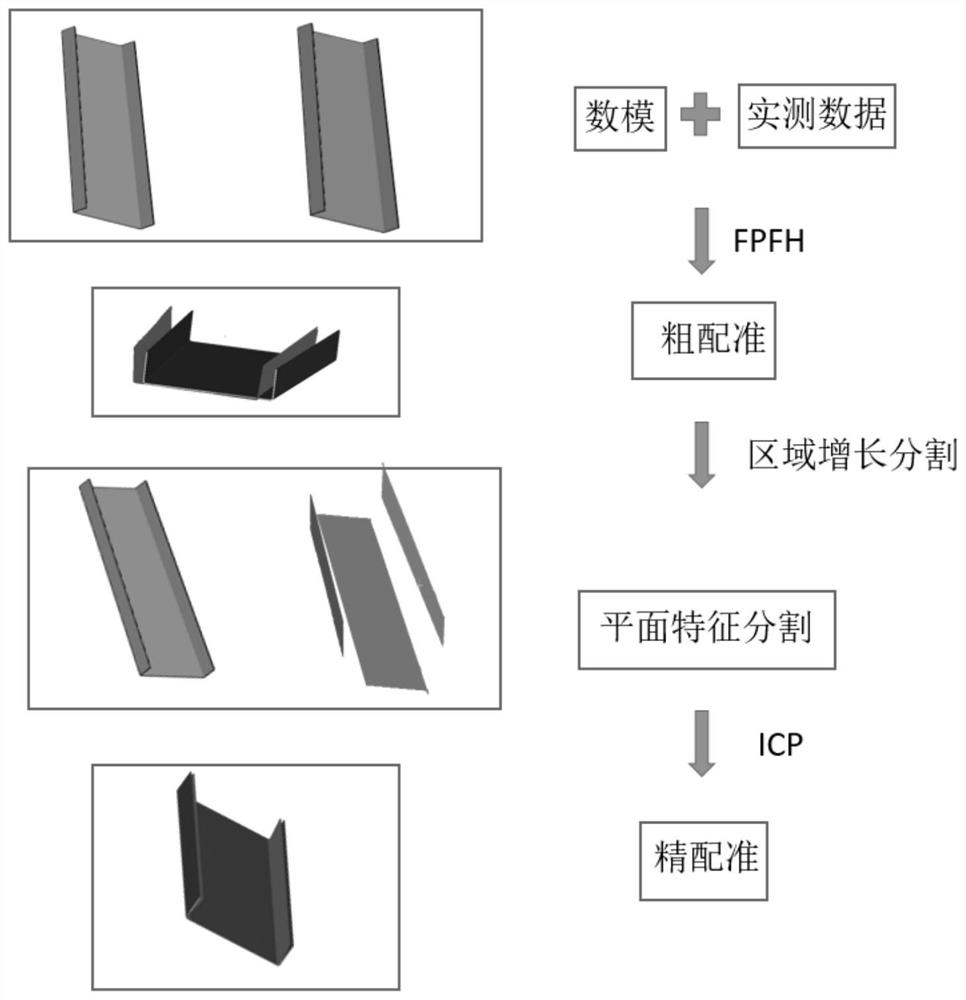

[0052] S2, use the fast point feature histogram feature description method to perform rough registration on the C-beam digital model and the measured point cloud data.

[0053] S3, performing segmentation processing and plane extraction on the measured point cloud data after rough registration, dividing the C-beam into three planes, and determining the bottom surface of the C-beam from them.

[0054] S4, using the bottom surface of the C-beam as a constraint for registration with the digital model of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com