Control system, rotary milking parlor, and method and computer program for controlling a rotary milking parlor

A control system and technology for milking parlors, applied in the field of computer programs and non-volatile data carriers, the control system of rotating milking parlors, can solve problems such as unreliable results, and achieve the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

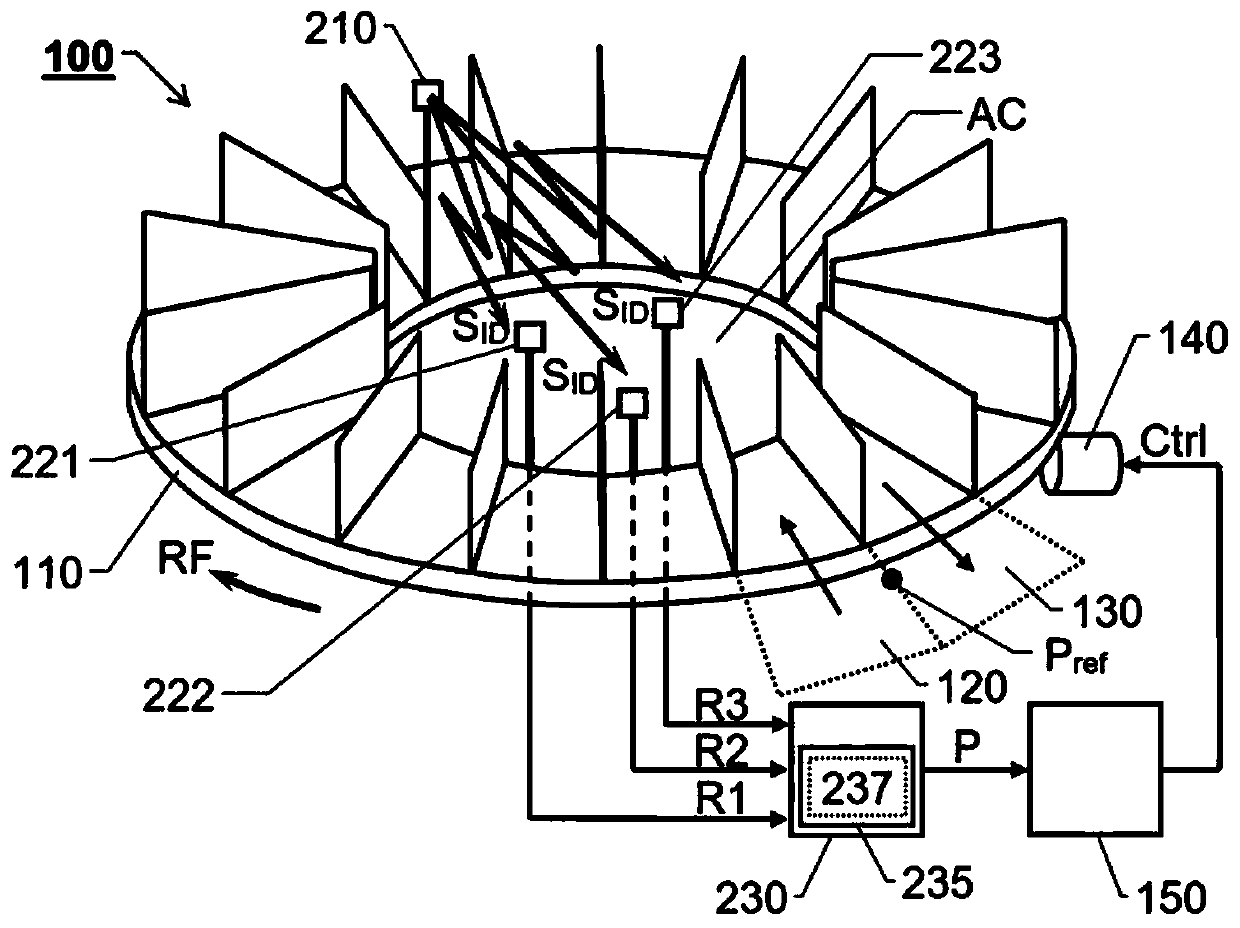

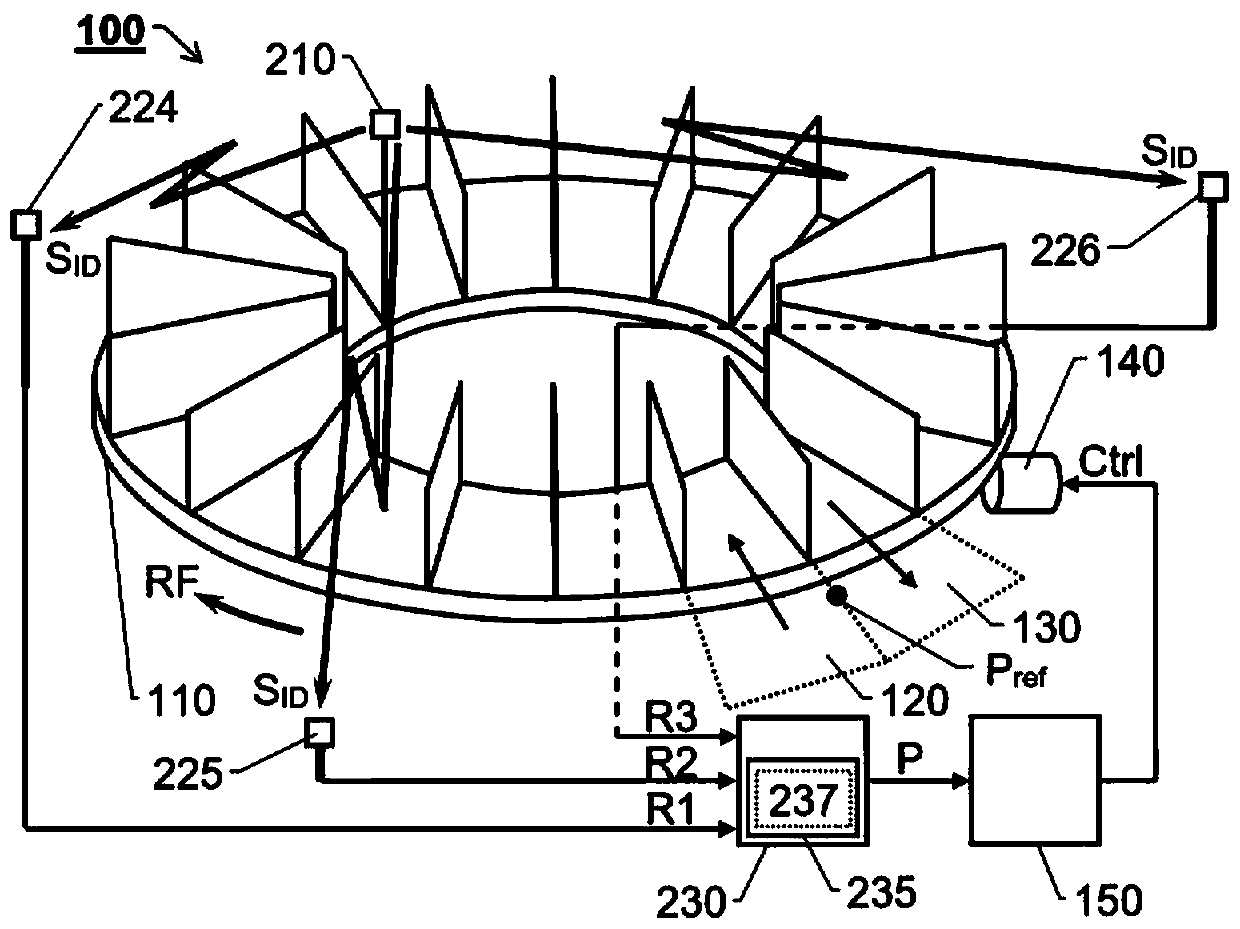

[0025] figure 1 A first example of a rotary milking parlor 100 and its control system according to an embodiment of the present invention is shown. The proposed control system comprises sensor means and a control unit 150 .

[0026] The sensor arrangement is configured to measure the movable platform 110 representing the carousel 100 relative to a static reference point P ref The positional parameter P. The control unit 150 is configured to receive the parameter P and based thereon to generate a control signal Ctrl affecting the motion of the movable platform 110, eg its rotational speed.

[0027] The sensor device again comprises a first transmitter unit 210 , at least three receiver stations 221 , 222 and 223 respectively and a processing unit 230 .

[0028] The first transmitter unit 210 has a first transmitter antenna and is configured to be placed on the movable platform 110 so as to move with any movement of the movable platform 110 . The first transmitter unit 210 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com