Hollow negative curvature photonic crystal fiber with high birefringence and low loss

A technology of photonic crystal fiber and high birefringence, which is applied in the direction of bundle optical fiber, light guide, optics, etc., can solve the problems of not studying the optical characteristics of HCF, and achieve excellent optical performance, broad application prospects, and large adjustable range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing, the present invention is described in further detail:

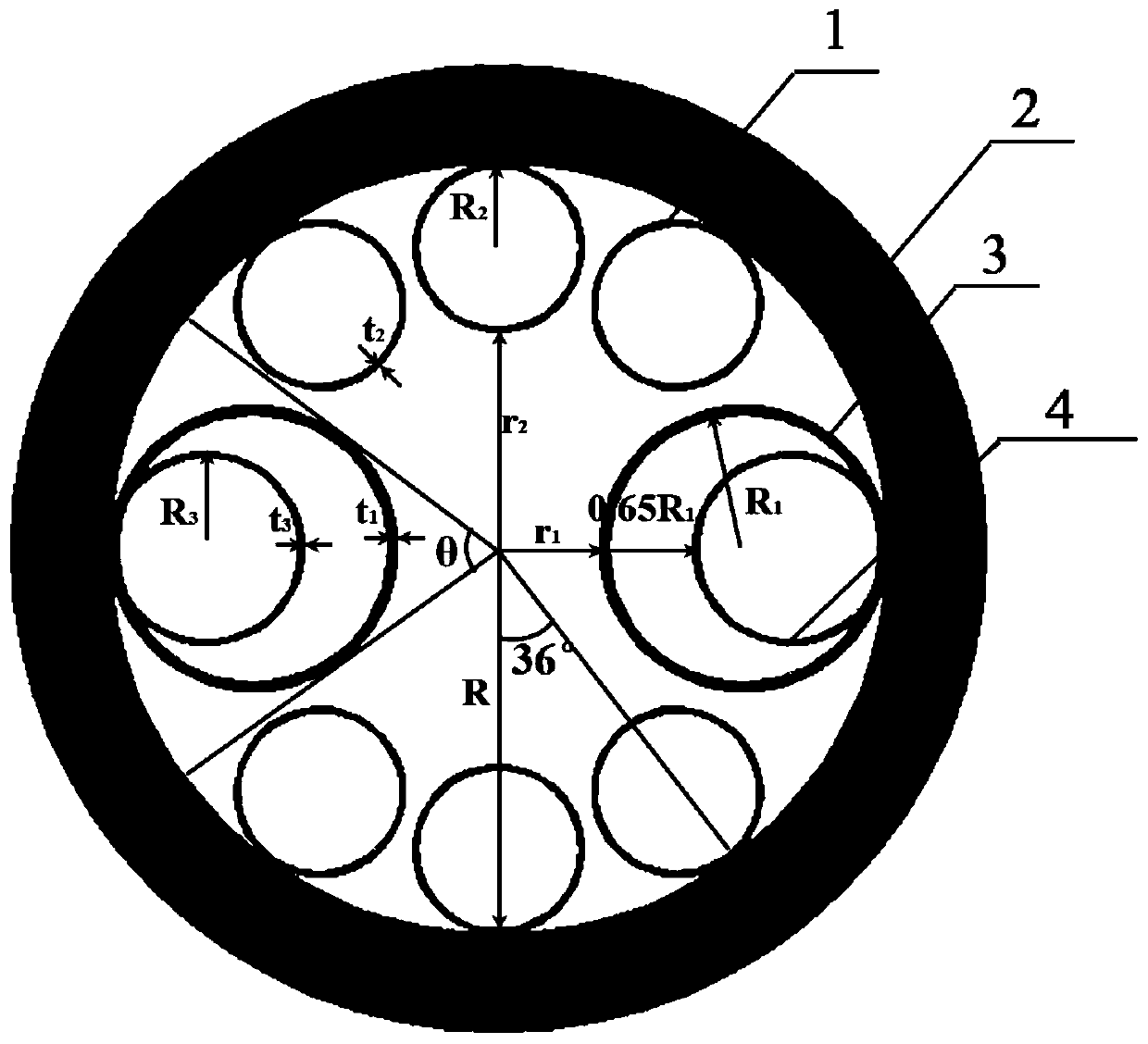

[0019] Such as figure 1 As shown, a hollow-core negative-curvature photonic crystal fiber with high birefringence and low loss includes an optical fiber tube body with a circular cross section and a hollow core inside, a tube wall fiber cladding 2 of the fiber tube body, and an optical fiber tube body Two large capillaries 3 with a circular cross-section and inscribed with the optical fiber cladding 2 are arranged symmetrically in the hollow core, and three large capillaries are arranged in the hollow core of the optical fiber body above and below between the two large capillaries 3. The same small capillary 1 whose cross section is circular and inscribed with the optical fiber cladding 2, and the two large capillaries 3 are provided with a middle capillary 4 with a circular cross section and inscribed with the large capillary 3. , the inscribed tangent point between...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com