Method and apparatus for modeling and designing multi-dimensional cellular structures for additive manufacturing

A cell and microstructure technology, applied in the direction of additive processing, 3D modeling, general control system, etc., can solve problems such as the limitations of general microstructure feature changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

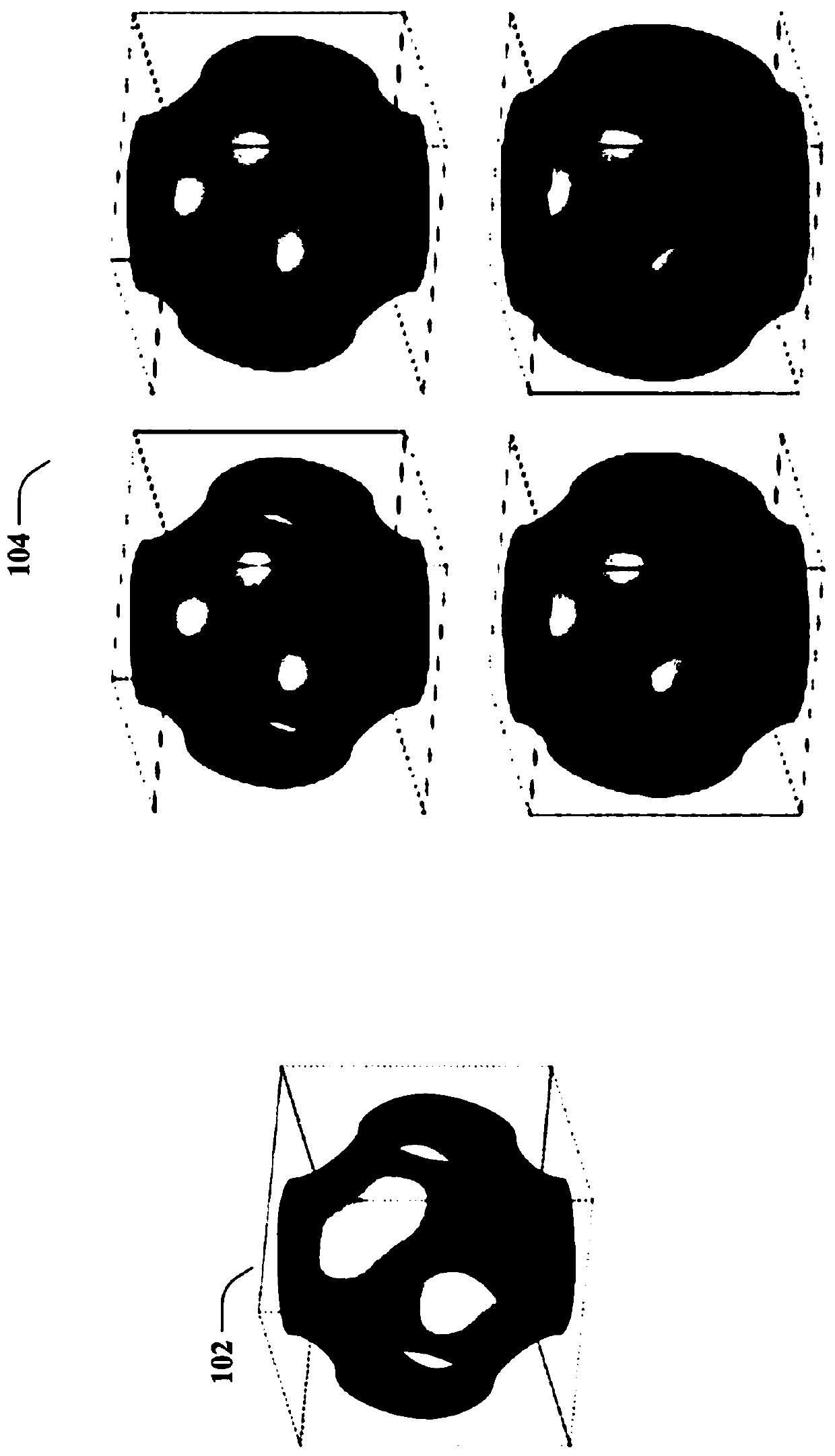

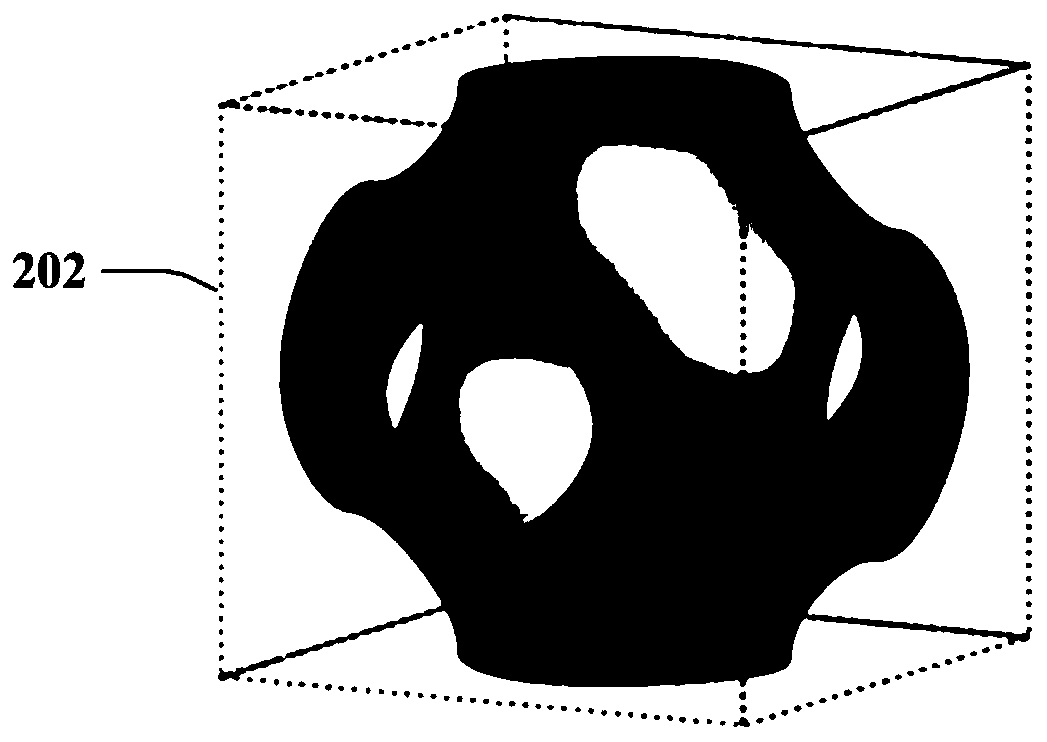

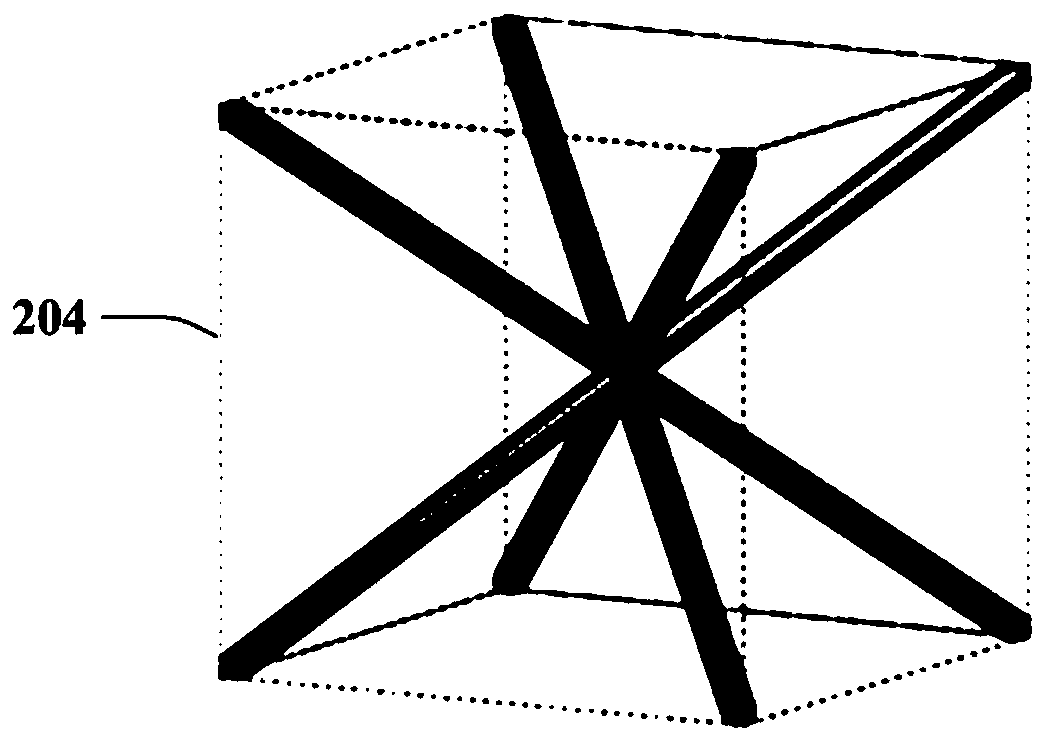

[0044] As mentioned earlier, the modeling of conformal and variable cellular structures has become an area of increasing research interest in design and fabrication processes. When designing variable cell structures, the goal is to ensure complete geometric connections between the cells of the microstructure. For microstructure cells whose interface between adjacent cells lacks complete geometric connections, the unconnected parts cannot bear external loads, and there are often fabrication difficulties in additive manufacturing. Areas of interface mismatch can lead to stress concentrations and should be completely avoided in the design.

[0045] A set of constraints can be set during the design process on the complete geometric connectivity between all microstructural cells. But this approach has severe constraints on the design options and leads to potential difficulties in convergence. Smoothing can be done as a post-processing to improve geometric connectivity after gen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com