Method for preparing purple perilla seed oil microcapsules by adding corn oligopeptides

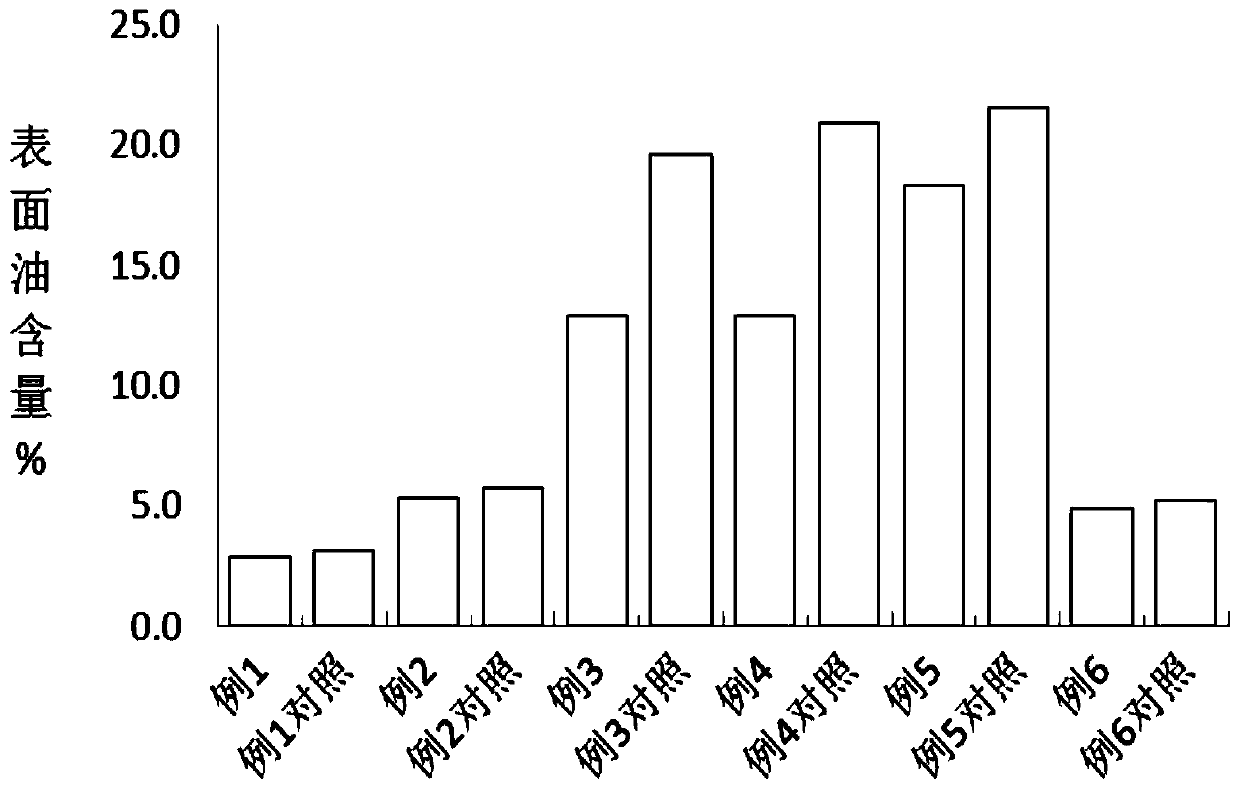

A technology of corn oligopeptide and perilla seed oil, which is applied in the direction of microcapsule preparation, microsphere preparation, food ingredients as antimicrobial preservation, etc., can solve the problems of industrial application limitations, reduce oil content, and meet nutrition and health demand, improve the effect of embedding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A method for preparing perilla seed oil microcapsules by adding corn oligopeptides, comprising the following steps:

[0039] A1: Weigh 250g of modified starch, add it to 1500g of 55°C hot water, stir at high speed to dissolve it completely, and form a water phase;

[0040] A2: Weigh 20g of corn oligopeptide, add it into the water phase, stir at high speed to dissolve it;

[0041] A3: Weigh 250g perilla seed oil, that is, the oil phase, and use a high-speed shearing machine to perform high-speed shearing on the water phase obtained in A2 at 10,000 rpm, and slowly add the oil phase, and keep shearing for 10 minutes after the oil phase is completely added , to obtain emulsion;

[0042] A4: Use a high-pressure homogenizer to homogenize the emulsion obtained in A3 at 30-60°C for 3 times, and the homogenization pressure is 40Mpa;

[0043] A5: Spray-dry the homogenized emulsion in A4, the air inlet temperature is 140°C, and the air outlet temperature is 85°C to obtain corn o...

Embodiment 2

[0051] A method for preparing perilla seed oil microcapsules by adding corn oligopeptides, comprising the following steps:

[0052] B1: Weigh 200g of gum arabic, 100g of sodium caseinate and 50g of soybean protein isolate, add them to 1750g of hot water at 55°C, stir at high speed to dissolve them completely, and form a water phase;

[0053] B2: Weigh 20g of corn oligopeptide, add it into the water phase, stir at high speed to dissolve it;

[0054] B3: Weigh 350g perilla seed oil, that is, the oil phase, and use a high-speed shearer to perform high-speed shearing on the water phase obtained in B2 at 10,000 rpm, and slowly add the oil phase. After the oil phase is completely added, keep shearing for 10 minutes. get an emulsion;

[0055] B4: Use a high-pressure homogenizer to homogenize the emulsion obtained in B3 at 30-60°C for 3 times, and the homogenization pressure is 40Mpa;

[0056] B5: Spray-dry the homogenized emulsion in B4, the air inlet temperature is 140°C, and the ...

Embodiment 3

[0060] A method for preparing perilla seed oil microcapsules by adding corn oligopeptides, comprising the following steps:

[0061] C1: Weigh 200g of soybean protein isolate and 100g of gum arabic, add them to 2000g of hot water at 55°C, stir at high speed to dissolve them completely, and form a water phase;

[0062] C2: Weigh 15g of corn oligopeptide, add it into the water phase, stir at high speed to dissolve it;

[0063] C3: Weigh 300g perilla seed oil, that is, the oil phase, and use the high-speed shearing machine C2 to cut the water phase at 10,000rpm at a high speed, and slowly add the oil phase. After the oil phase is completely added, keep shearing for 10 minutes to obtain Emulsion;

[0064] C4: Use a high-pressure homogenizer to homogenize the emulsion obtained in C3 at 30-60°C for 3 times, and the homogenization pressure is 40Mpa;

[0065] C5: Spray-dry the homogenized emulsion in C4, the air inlet temperature is 140°C, and the air outlet temperature is 83°C, to o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com